In many industrial filtration projects, achieving efficient solid-liquid separation can be a real challenge. When filtration speed, cake dryness, and equipment reliability become critical, the plate and frame filter press stands out as one of the most proven solutions in the field.

A plate and frame filter press is a pressure-driven filtration system designed to separate solids from liquids using a series of alternating plates and frames lined with filter cloths. The slurry is pumped into these chambers, where liquid passes through the cloth while solids remain to form a compact filter cake.

Let’s explore how it works and why it remains a core choice across industries.

What Are The Types Of Plate And Frame Filter Presses?

Depending on how automated, how much capacity, and how the control system works, plate and frame filter presses come in different shapes and sizes.

There are three main types of filter presses: fully automatic, semi-automatic, and manual. Each model is made to meet different needs for running and making things.

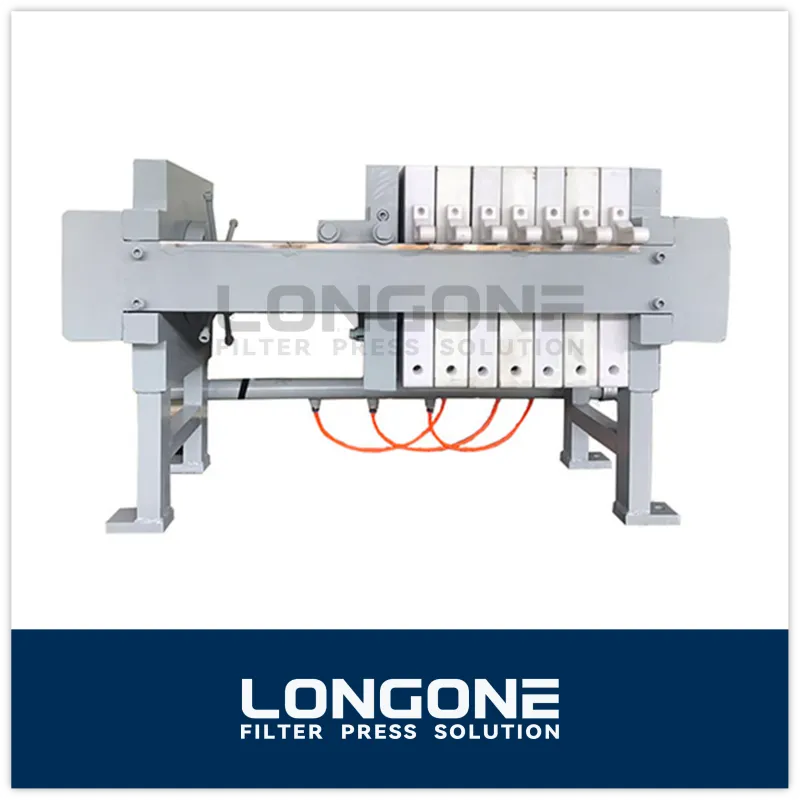

Manual Frame And Plate Filter Press

This type is the most basic version, operated by manual tightening or hydraulic hand pumps. It is suitable for small-scale operations, laboratories, or pilot testing lines. Its structure is simple, cost-effective, and easy to maintain, making it ideal for applications where throughput is not the priority.

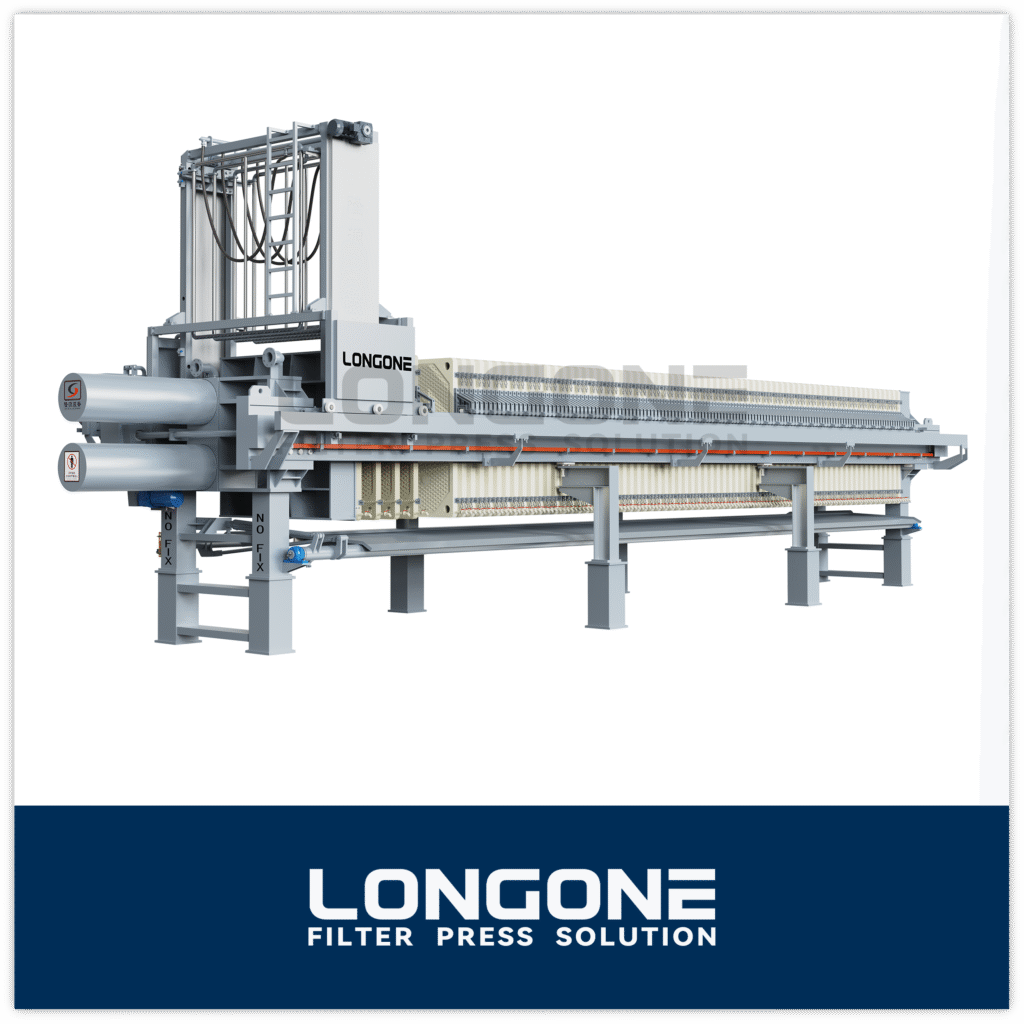

Semi-Automatic Frame And Plate Filter Press

This model combines manual setup with partial automation such as hydraulic plate shifting or cake discharge mechanisms. It offers higher efficiency and reduced labor compared to manual presses. Operators benefit from consistent filtration pressure and faster cycle times.

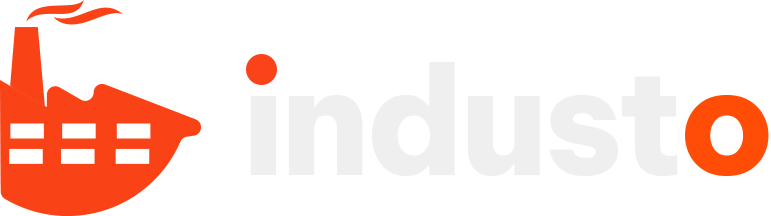

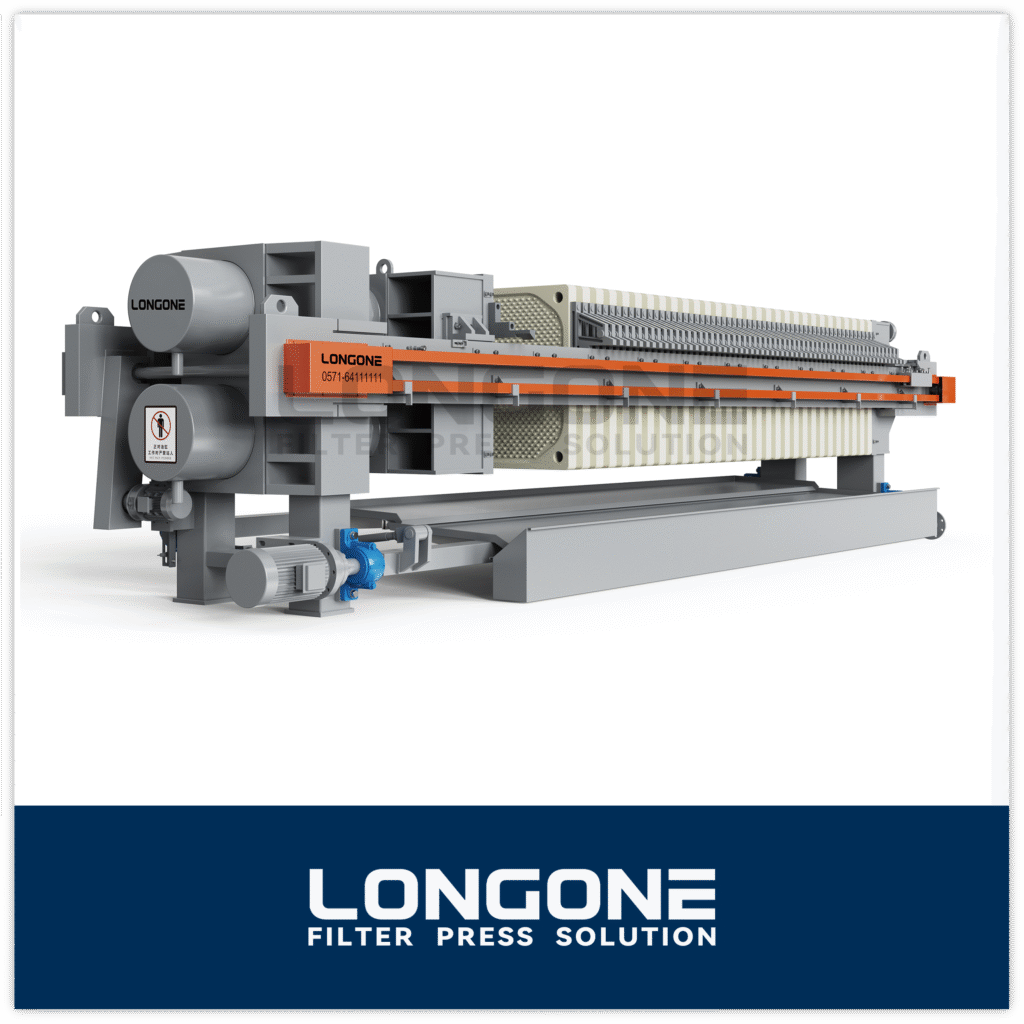

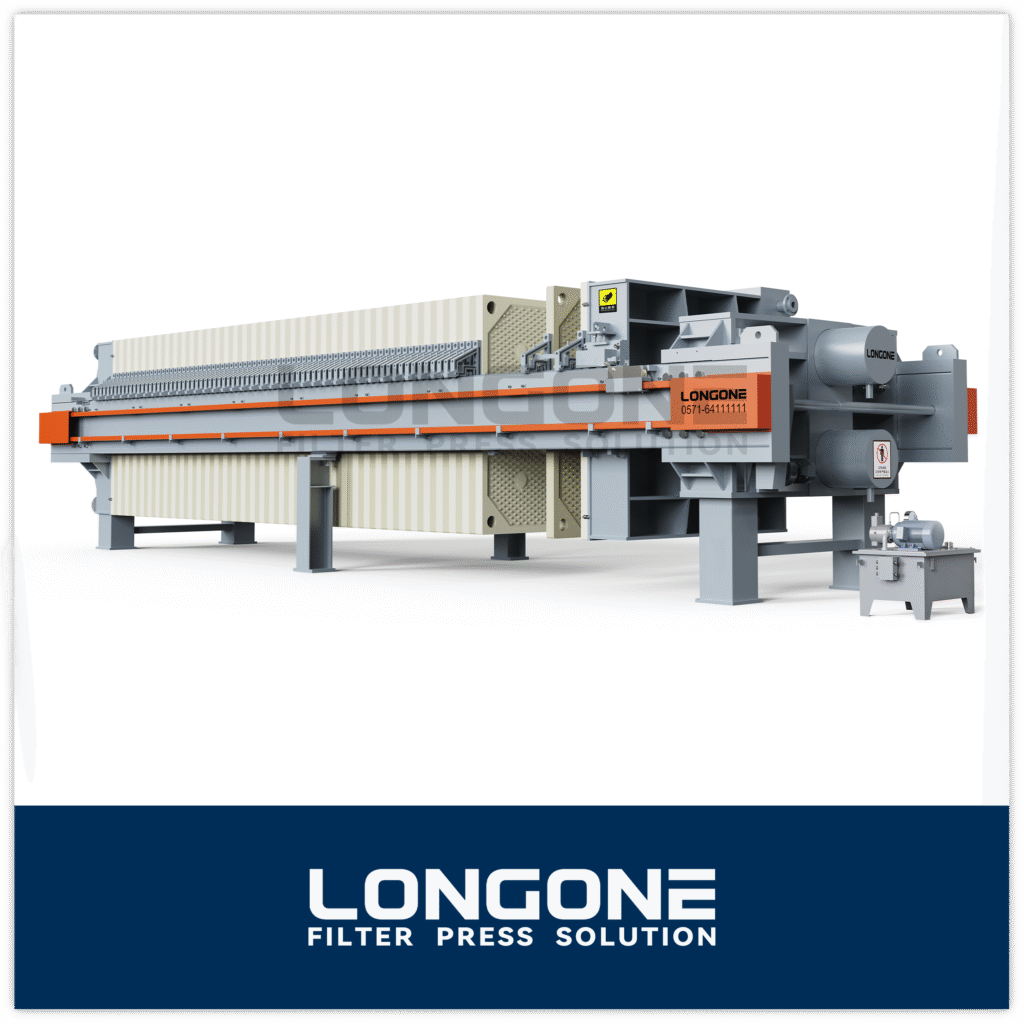

Fullly Automatic Frame And Plate Filter Press

Fully automatic systems are equipped with PLC control panels, automatic plate shifters, and remote monitoring. These systems are great for big industrial uses that need to run all the time, need little work, and need to control filtration very precisely.

In short, the best model depends on how big the project is, how often it is made, and how much automation is needed.

How Does A Plate And Frame Filter Press Work?

Understanding the plate and frame filter press working principle is key to maximizing performance and efficiency. The process can be divided into several main steps:

- Feeding: Slurry is pumped into the press chambers formed between alternating plates and frames.

- Filtration: Under high pressure, liquid passes through the filter cloth while solids are retained, gradually forming a filter cake.

- Cake Formation: The pressure continues until a compact, dry cake is built up in the chambers.

- Filtrate Discharge: The filtered liquid (filtrate) exits through drainage ports for further use or disposal.

- Cake Release: Once filtration ends, the plates are separated, and the solid cakes are discharged.

- Cleaning & Preparation: Filter cloths are cleaned, and the system is prepared for the next cycle.

This plate and frame filter press working process is entirely pressure-driven and allows for high filtration efficiency and low moisture content in the filter cake.

What Are The Uses Of A Plate And Frame Filter Press?

Plate and frame filter presses are used in many different industries because they are very precise and can be used in many different ways.

In the chemical processing, mining and minerals, food and drink, pharmaceutical, and wastewater treatment industries, they are often used. These presses do things like filter mineral concentrates, clarify oil, and remove water from sludge.

The system can also be used for both small-scale testing in a lab and large-scale continuous production lines, giving manufacturers and research institutions both options.

In short, the plate and frame filter press is still an important piece of equipment for separating liquids from solids.

What Are The Pros and Cons Of A Plate And Frame Filter Press?

The plate and frame filter press, like any other piece of industrial equipment, has its pros and cons. Knowing both sides helps you choose the right equipment and keep it in good shape.

The plate and frame filter press has a lot of benefits, such as being able to separate things very well, being strong, and being able to be used in many different ways. But there are some downsides to think about, like the possibility of leaks, clogs, and a bigger footprint.

| Advantages | Disadvantages |

|---|---|

| High filtration efficiency with dry filter cakes | Possibility of leakage from non-gasketed plates |

| Strong frame design for high-pressure operation | Filter cloth may clog and require regular cleaning |

| Customizable materials and automation levels | Occupies more space than other filter designs |

| Reduced labor in semi/fully automatic models | Maintenance and cake removal can be time-consuming |

| Long service life and stable performance | Higher initial investment for automatic systems |

Overall, while not perfect, the plate and frame filter press remains one of the most reliable and cost-effective filtration systems available.

How To Choose The Right Plate And Frame Filter Press?

Selecting the right press requires understanding your application’s specific requirements. Here are key factors to consider:

- Type of Slurry: Identify solid particle size, viscosity, and chemical composition to choose suitable plate material and cloth type.

- Filtration Volume: Determine daily or hourly throughput to size the press capacity correctly.

- Automation Level: Choose manual for small batches, semi-automatic for medium workloads, or fully automatic for continuous operation.

- Operating Pressure: Ensure the design pressure matches the process needs to achieve target cake dryness.

- Material Construction: For corrosive environments, consider stainless steel or reinforced polypropylene frames.

A well-matched system improves filtration efficiency, reduces maintenance downtime, and extends overall equipment life.

Summary

In conclusion, the plate and frame filter press plays an essential role in solid-liquid separation across industries. Its efficiency, versatility, and durability make it a cornerstone of industrial filtration technology.

We from Longone Corporation provide durable, high-efficiency plate and frame filter presses tailored to industrial and municipal applications, ensuring consistent performance and long-term reliability.

For inquiries or technical consultation, contact us at info@longonefiltra.com