With increasing emphasis on environmental protection, wastewater and sludge separation is a crucial step in achieving environmental compliance and resource recycling in modern industry, and filter presses are the core equipment for achieving this goal.

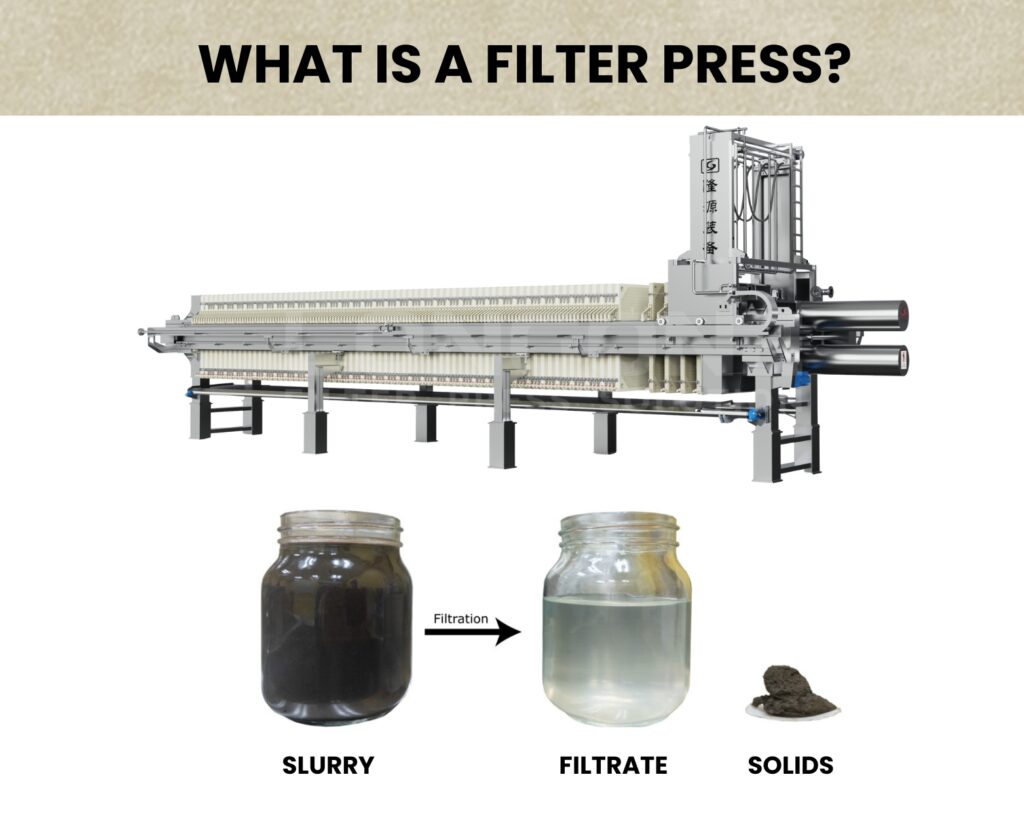

A filter press is an industrial device that uses pressure to separate solids and liquids in sludge. It operates in batches, producing a solid “filter cake” and a clean filtrate, providing efficient dewatering solutions for the mining, chemical, and wastewater treatment industries.

Let’s take a closer look at what is a filter press is and how it works in industrial filtration.

What is a Filter Press?

A filter press is a type of filtration machine that uses pressure to separate solids from liquids in slurry mixtures. It is used a lot in mining, chemicals, pharmaceuticals, food processing, and treating municipal wastewater.

The main job of a filter press is to lower the amount of water in sludge or slurry so that it can be turned into “filter cakes” that are easy to handle. It is especially useful in processes that need a lot of dryness or where it is important to reuse the filtrate.

A filter press is very important for handling resources and reducing waste, whether you’re working with minerals or biological sludge.

Filter presses are often used in chemistry labs and factories to separate precipitates or get useful byproducts back from liquid reactions.

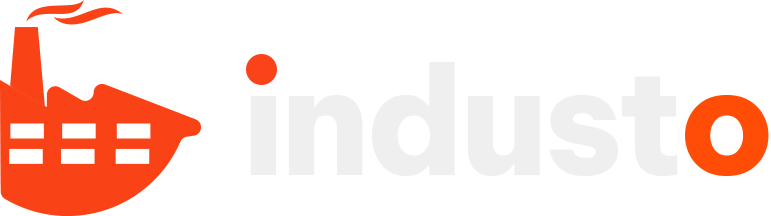

Most filter press diagrams show stacked plates with chambers where slurry is injected and then pressure is applied to separate the two.

Key Components of a Filter Press

Every filter press is composed of several essential parts that work together in synchronization:

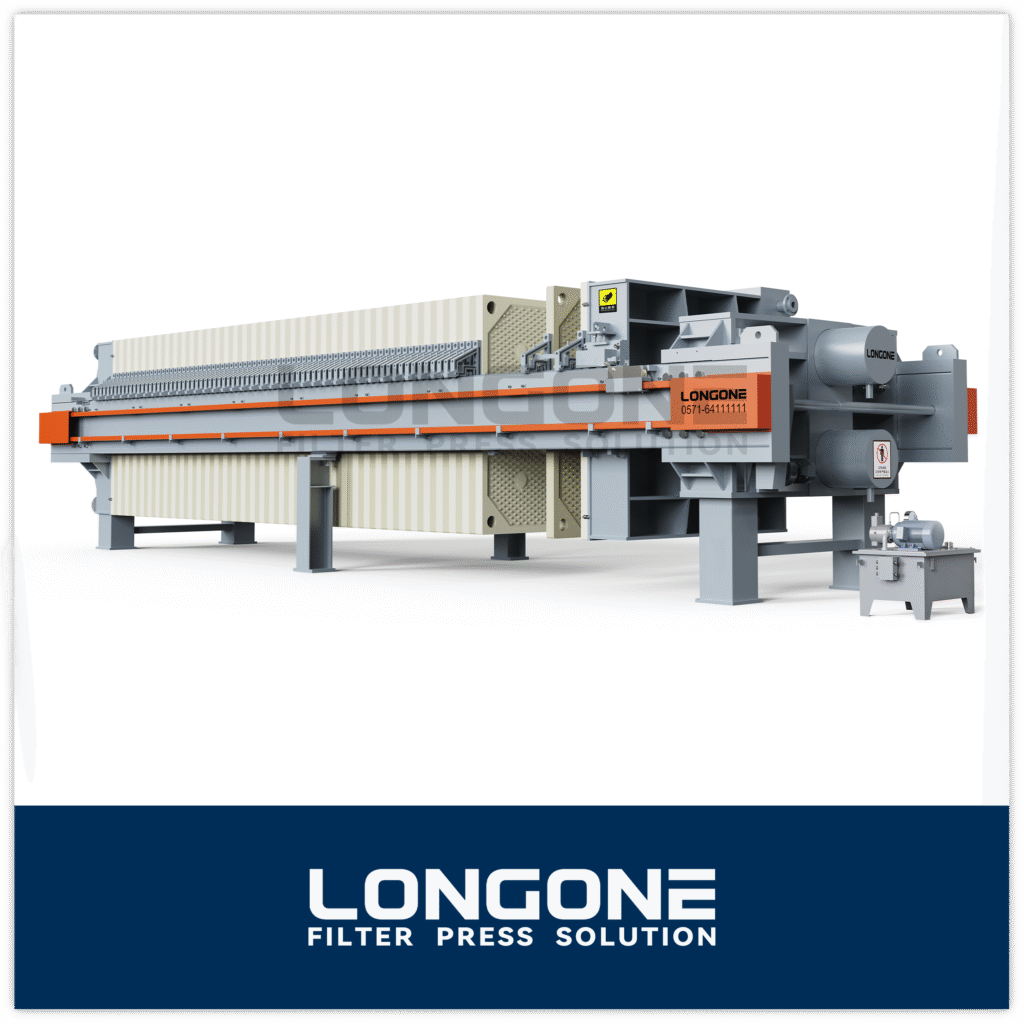

- Filter Plates: Usually made of polypropylene or stainless steel, these plates form chambers where slurry is processed.

- Filter Cloths: These are stretched across each plate and capture the solid particles.

- Frame: The steel structure that supports the plates and handles the filtration load.

- Hydraulic System: Provides the pressure needed to compress plates and drive the separation process.

- Feeding Pump & Manifold: Deliver the slurry into the press uniformly.

These components determine the performance, durability, and maintenance needs of the press.

Filter plates, cloths, frame, and hydraulics form the core of any filter press.

What Are The Types of Filter Press?

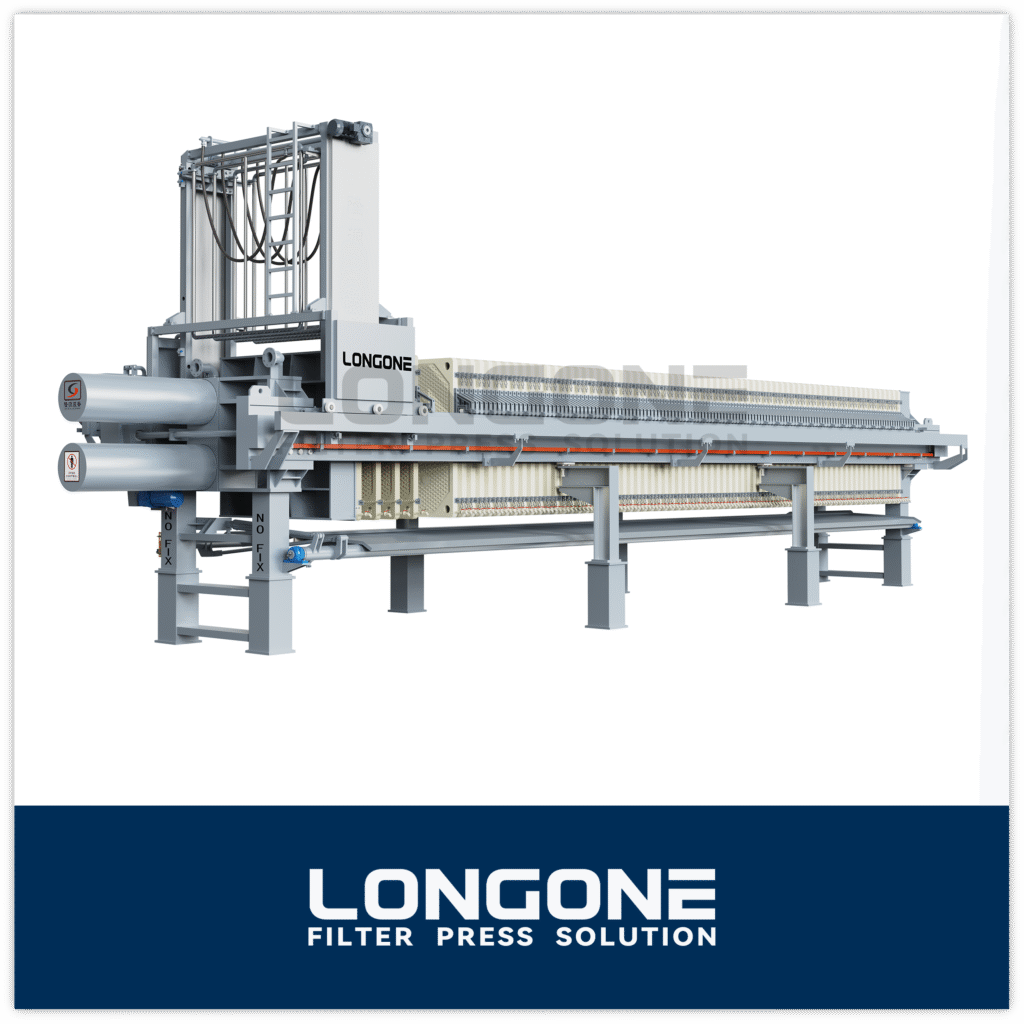

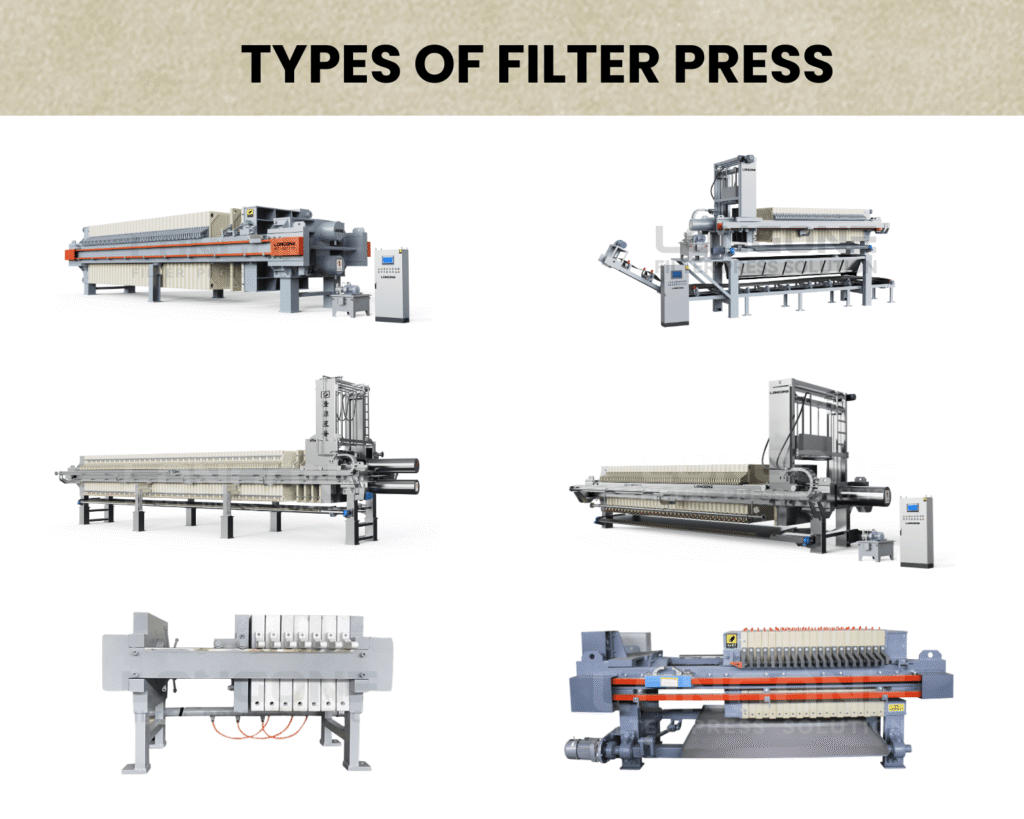

There are multiple types of filter presses available depending on specific industrial requirements:

- Plate and Frame Filter Press: The oldest design, alternating solid plates and hollow frames. Good for low-pressure applications.

- Chamber Filter Press: Plates create chambers to hold slurry. Efficient and commonly used in wastewater treatment.

- Membrane Filter Press: Uses flexible membranes to squeeze the cake further, reducing cake moisture content significantly.

- Automatic Filter Press: Fully automated, suitable for large-scale operations with minimal manual labor.

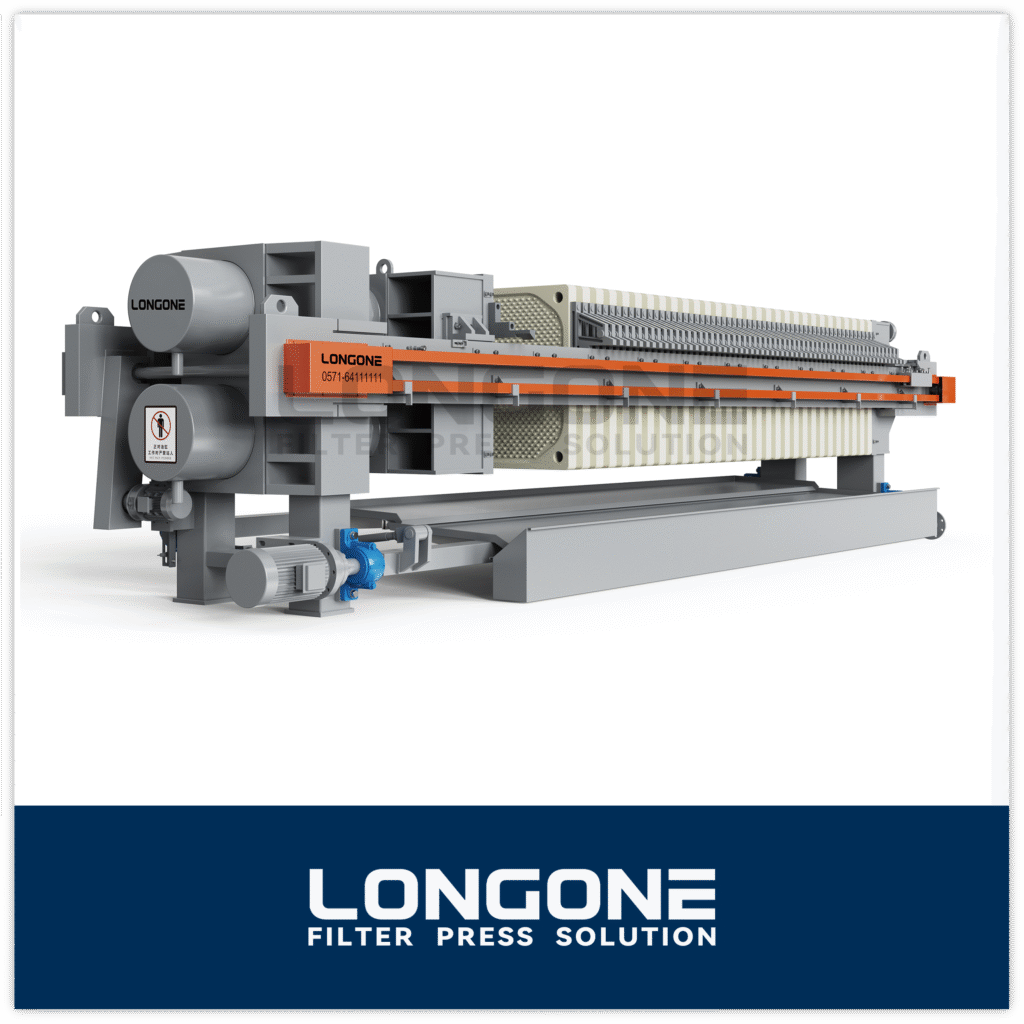

- Stainless Steel Filter Press: Ideal for sanitary applications like food, pharmaceuticals, and fine chemicals.

- Laboratory Filter Press: Small-scale units used in R&D and sample testing.

Types of filter press vary by material, level of automation, and dewatering capability.

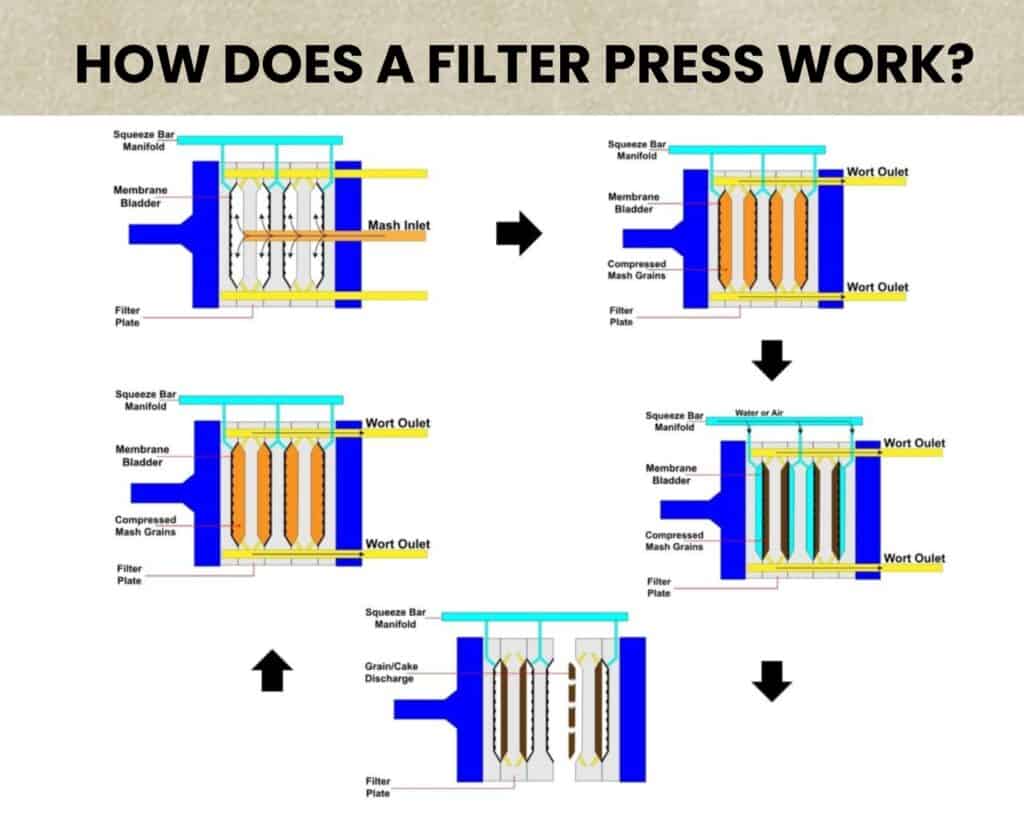

How Does a Filter Press Work?

Here’s a breakdown of the filter press working principle in a simple step-by-step table:

| Step | Description |

|---|---|

| 1. Slurry Filling | The slurry (mixture of solids and liquid) is pumped into the chambers formed between the filter plates. |

| 2. Pressure Filtration | High pressure is applied via hydraulic or mechanical systems, forcing the liquid through the filter cloth while solids are trapped inside the chamber. |

| 3. Cake Formation | As more slurry enters, the solids accumulate and form a dense, dry “filter cake” on the surface of the cloth. |

| 4. Filtrate Discharge | The clear liquid (filtrate) passes through the cloth and exits via discharge channels for reuse or disposal. |

| 5. Cake Release | After the filtration cycle ends, the plates are separated, and the solid cake falls off, either manually or automatically depending on the system type. |

| 6. Optional Drying/Washing | Some systems may add air blow or washing cycles to improve cake dryness or cleanliness, especially in chemical or food applications. |

A filter press works through a batch-based pressure system that separates solids from liquids effectively.

What Are the Applications of Filter Presses?

What is a filter press used for?—Plenty!

Filter presses are applied across industries where liquid-solid separation is essential:

- Mining & Mineral Processing: To recover minerals and dewater tailings.

- Municipal Wastewater: Sludge dewatering for easier disposal or incineration.

- Chemical Manufacturing: For purifying liquids and capturing valuable solids.

- Food & Beverage: In sugar refining, juice clarification, and brewing.

- Pharmaceuticals: To separate active compounds or recover residues.

- Oil Industry: For oil separation and catalyst recovery.

What is a filter press in chemistry? It’s used to recover precipitates or purify chemical mixtures through filtration.

What Are the Advantages of Filter Presses?

Filter presses offer several performance and cost benefits:

- High Efficiency: Achieve low filter cake moisture and high solid capture rates.

- Consistent Results: Reliable, repeatable filtration performance.

- Durable Design: Long service life with proper maintenance.

- Customizable: Can be tailored to slurry properties and processing needs.

- Automatable: Advanced models support full automation for labor savings.

- Eco-Friendly: Reduces liquid waste and allows for water recycling.

They are ideal for operations where throughput, dryness, and space optimization matter.

How to Choose the Right Filter Press?

Selecting the right unit involves evaluating multiple factors:

- Slurry Type: Particle size, abrasiveness, and chemical composition.

- Desired Output: Cake dryness, filtrate clarity, and batch size.

- Operational Mode: Manual, semi-automatic, or fully automatic?

- Material Construction: Stainless steel for hygiene-sensitive industries.

- Space & Utilities: Available floor space, water/air/power supply.

- After-sales Support: Spare parts, technical guidance, remote support.

Conclusion

From food factories to mining operations, filter presses deliver effective liquid-solid separation. Their efficiency, versatility, and scalability make them essential for industries worldwide. And with customized solutions available, they fit nearly any production line.Filter presses are essential tools for clean, cost-effective separation. At Longone, we specialize in customized filter press solutions built for real-world industrial challenges. Whether you need higher throughput, better cake dryness, or automated systems, we’re here to help with expert engineering and global service support.

FAQ

Q1: What is the most common type of filter press used in industry?

The chamber filter press is the most widely used, thanks to its balance of efficiency, cost, and automation compatibility.

Q2: What are the disadvantages of filter presses?

They operate in batches, require downtime for cake discharge, and need regular maintenance of filter cloths and hydraulic systems.

Q3: What is the alternative to a filter press?

Alternatives include centrifuges, belt presses, and screw presses—each with trade-offs in cost, space, and performance.

Q4: What maintenance is required for different filter press types?

Regular cleaning of filter cloths, checking for hydraulic fluid leaks, inspecting plates for wear, and ensuring proper alignment are key to long life.