Description

Introduction to Chamber filter presses:

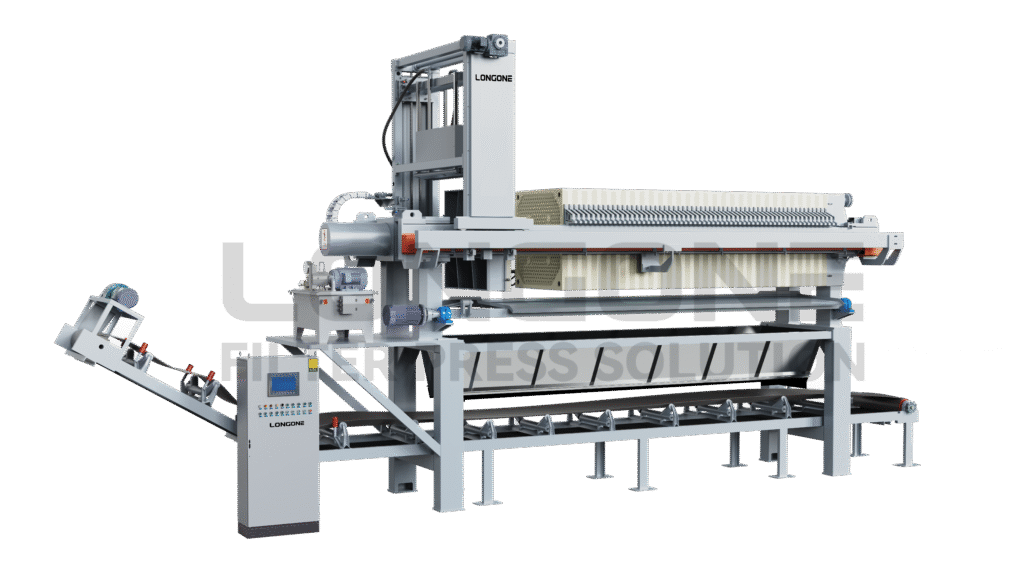

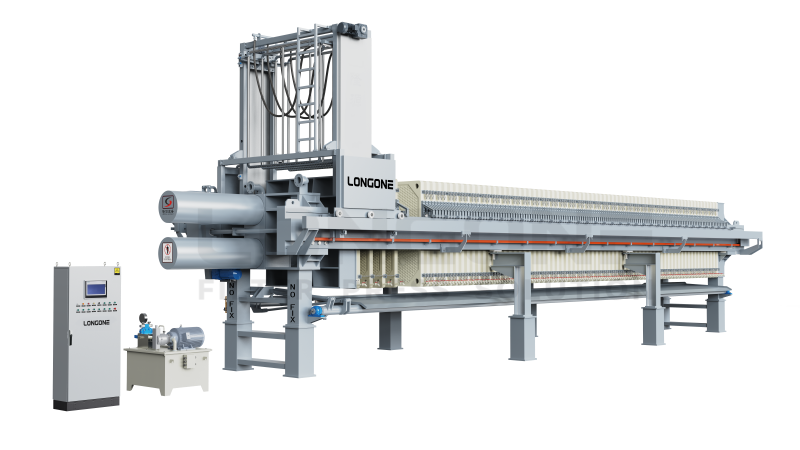

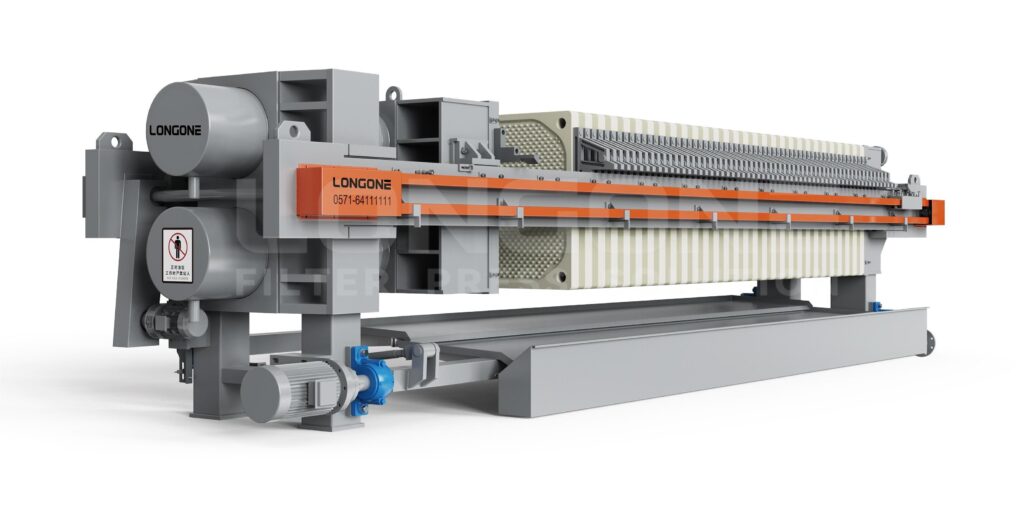

The chamber filter press operates on the principle of separating solids from liquids through a filtration process. The recessed chamber filter press consists of a series of filter plates. The filter press plates are pressed together under hydraulic pressure to form a range of chambers. The chambers are filled with the slurry (mixture of solids and liquids).

Features of Chamber filter press:

The recessed chamber filter press is a technologically advanced separation machinery product that integrates machinery, electricity, and hydraulics. This filter press consists of five main parts: the frame part, the filter part (including filter plates, membrane plates, and filter cloths), the plate pulling part, the hydraulic part, and the electrical control part.

The frame part of the chamber filter press serves as the main body of the machine, supporting the filter mechanism and connecting other components. It primarily comprises the thrust plate, pressing plate, cylinder and main beam.

The filtration part of the automatic chamber filter press consists of filter plates arranged on the main beam in a specific order, filter cloth sandwiched between the filter plates, and membrane plates. The filter plates and membrane plates, along with the filter cloth, are alternately arranged to form several independent filter chambers. This arrangement ensures efficient separation and filtration processes.

The automatic plate pulling part of the filter press includes a variable frequency motor, plate shifter, transmission mechanism, and pause device, allowing for automated and precise movement of the filter plates.

The hydraulic part of the filter press provides the power to drive the pressing plate to press or loosen the filter plates. It is equipped with a plunger pump and various control valves.

The electronic control part serves as the control center of the entire filter press system. The electronic control system allows for easy monitoring and adjustment of the filter press parameters, enhancing the overall performance and reliability of the automatic chamber filter press.

Basic Parameters of Chamber filter press:

Filter plate size(mm) 400*400 to 2000*2000

Filter area(㎡) 1 to 1080

Filter pressure(MPa) ≤2.0

Chamber volume(m³) 0.015 to 22

Plate Number(Pcs) 5 to 155

Filter plate material Reinforced PP

Optional Features PLC control, Drip tray, Automated pull plates, Membrane plate, cake washable,etc

Applications mining, chemical processing, food and beverage,etc

Warranty 1 year

Certifications ISO9001, ISO45001, ISO14001

Advantages of Chamber filter press:

Robust Construction: The chamber plate filter press is built with durable materials and advanced engineering, ensuring reliability and longevity.

Versatile Applications: The filter press is suitable for a wide range of industries including mining, chemical processing, and environmental protection.

Easy Operation: The filter press filters have user-friendly design with intuitive controls, facilitating straightforward operation and maintenance.

Customizable Configurations: The chamber filter press is available in various sizes, filtering areas, and optional features to meet specific operational requirements.

High Filtration Capacity: The automatic chamber filter press is capable of handling large volumes of slurry efficiently, reducing processing time and costs.

Applications of Chamber Filter Press:

Mining: Extracting and processing minerals by separating solids and liquids in mining slurry.

Chemical Processing: Filtering chemical compounds and solutions to isolate pure substances or remove impurities.

Food and Beverage: Clarifying liquids in food processing to achieve purity and compliance with hygiene standards.

Environmental Protection: Treating wastewater and industrial effluents by removing contaminants for safe discharge or reuse.

Pharmaceuticals: Filtering pharmaceutical formulations to ensure product purity and compliance with regulatory standards.

After-Sales Service and Support:

Our filter press products are backed by a one-year warranty and comprehensive technical support, ensuring optimal performance throughout the product lifecycle. Additionally, we offer lifelong maintenance services to keep your filter press in top condition. We ensure that software updates and upgrades are provided free of charge, keeping your chamber plate filter press equipped with the latest technology. Furthermore, we offer a long-term preferential supply of spare parts and accessories, ensuring that your filter press filters remains operational and efficient for many years.

Equipment of Production and Processing:

Premium Screw Estruder: Whether it’s removing rust, scale, or other contaminants from metal surfaces, our shot blasting machines ensure a uniform, high-quality finish every time.

Advanced Robotic Welding Systems: At the forefront of automation, Longone’s robotic welding systems redefine precision and efficiency in welding applications. Longone’s robots are programmed to execute complex welding tasks with unmatched accuracy, ensuring consistent weld quality and reduced scrap rates.

5-Axis Processing Line For Filter Plate: Pioneering automation, Longone’s 5-axis machines redefine precision & efficiency in filter plate production. Unmatched accuracy tackles intricate tasks, ensuring quality & reducing waste.

Oil Hydraulic Press: Powerful, precise & reliable, harnessing the force of hydraulics for a wide range of pressing applications.

Company profile:

At Longone, we are dedicated to providing cutting-edge filtration solutions to industries across the globe. With a legacy of innovation and excellence, we have established ourselves as a leading manufacturer of filter presses and related equipment.

Our Core Products:

Filter Presses: Our standard filter presses are designed for a wide range of applications, offering high efficiency and reliability in solid-liquid separation processes.

Filter Plates:

Our Commitment:

At Longone, we are committed to delivering not only top-quality products but also exceptional customer service. Our team of experts is always ready to assist you with your filtration needs, from consultation to after-sales support.

Join Us on the Journey to Cleaner, Safer, and More Efficient Filtration Solutions.

Contact us today to discover how our filter presses can enhance your operations and contribute to a more sustainable future.

Reviews

There are no reviews yet.