We are a professional lab filter press manufacturer that focuses on making laboratory-scale filtration equipment that works as well as industrial-grade equipment but is smaller and easier to use. Our lab filter presses are made for research institutions, pilot plants, universities, and small-batch production settings that need solid-liquid separation that is accurate, repeatable, and quick. We offer solutions that help with process development, quality control, and material testing in many industries. Our products are customizable, built to last, and have high filtration accuracy.

- Comprehensive Manufacturing Capability: Full OEM/ODM service covering sintering, machining, welding, polishing, painting, and assembly.

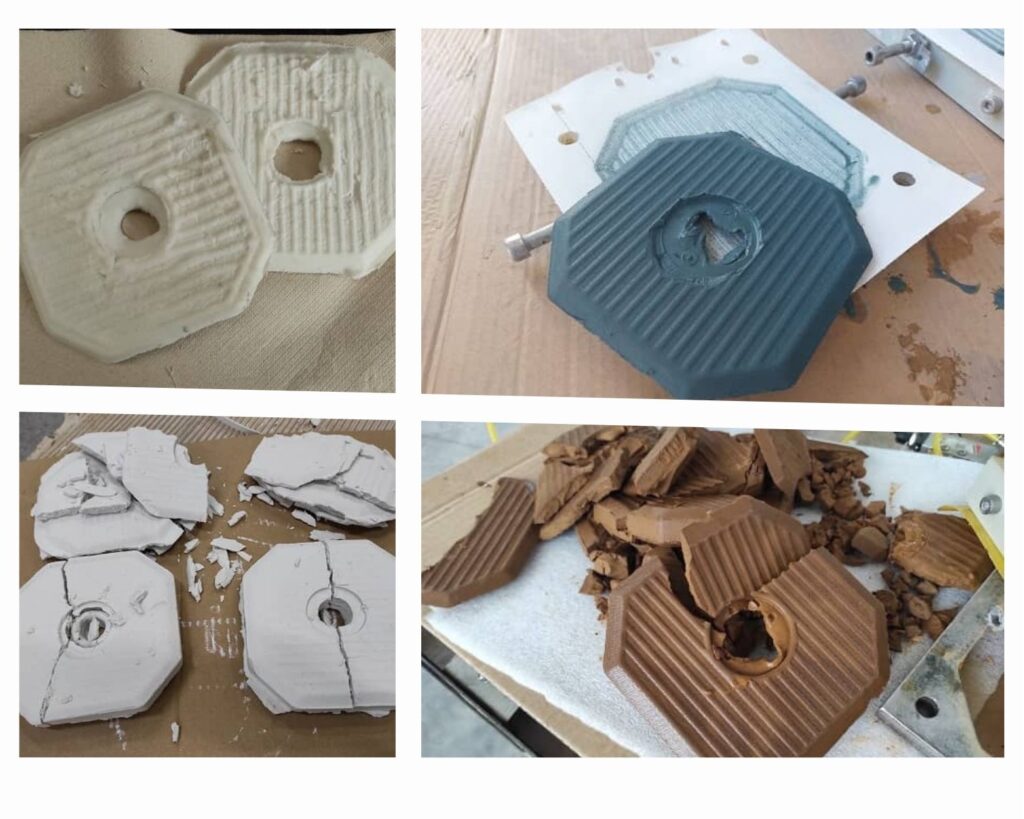

- High Filtration Precision: Allows for precise lab analysis by supporting micro-filtration, cake washing, and high-pressure dewatering.

- Customizable Designs: You can change the filter plate material, the number of plates, the structure, the feeding method, and the extra systems to fit your project.

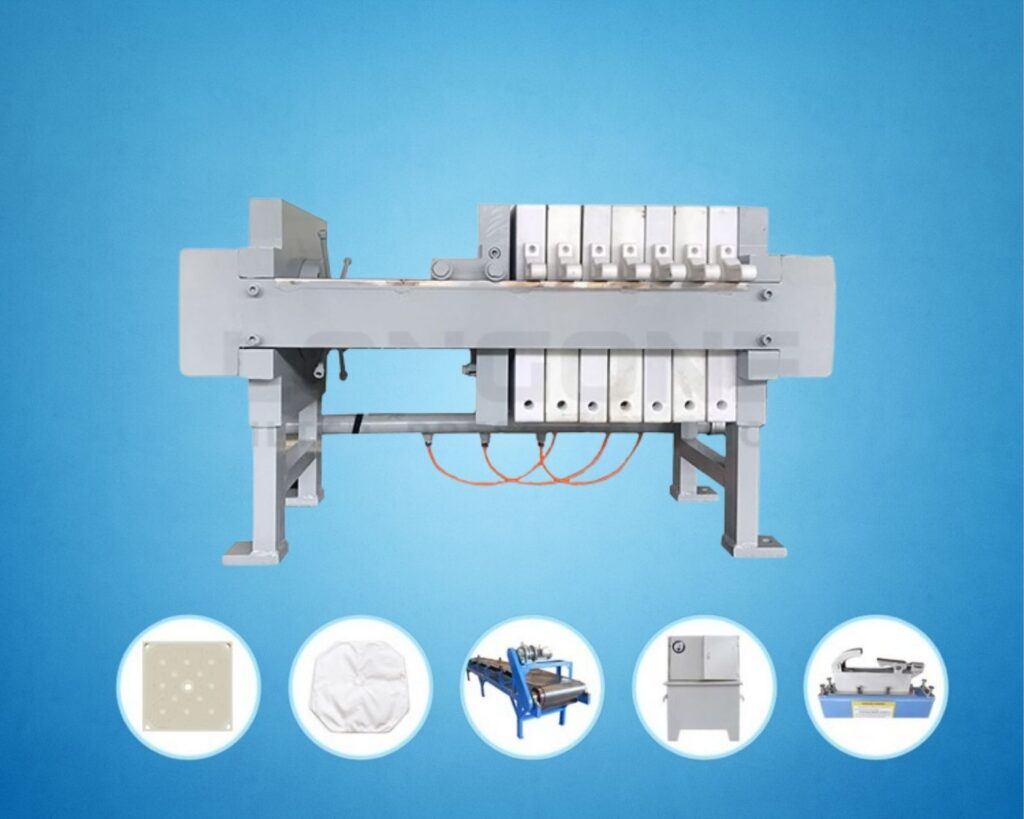

A laboratory filter press is a compact, small-scale solid–liquid separation device designed to replicate the working principles of industrial filter presses. Built with precision components such as PP or stainless steel filter plates, micro-filtration membranes, and a controlled feeding system, it allows researchers to achieve accurate and repeatable filtration results within a laboratory environment.

The primary purpose of a laboratory filter press is to evaluate filtration behavior, optimize process parameters, and develop customized filtration solutions before industrial-scale production. It is widely used for cake formation tests, washing efficiency studies, dewatering performance analysis, and small-batch material processing across chemical, pharmaceutical, environmental, and research fields.

Filter Press manufacturer

Product Name: Lab Filter Press

Brand Name: LONGONE

Hydraulic System: Manual, semi-automatic, or fully automatic options

Customization: Supported

Filter Press Price: Negotiable

Minimum Order Quantity: 1 unit

Applications: It is suitable for all small-scale processes that require filtration, dehydration, and washing of suspensions.

Technical Specifications

| Specs | Details |

|---|---|

| Filtration Area | 0.016m² to 10.0m² |

| Feeding Type | Top feeding, center feeding, corner feeding |

| Filter Pressure | 0.6 MPa to 6.0 MPa |

| Filtration Temperature | -40℃ to 120℃ |

| Filter Plates Size | 500mm×500mm, 630mm×630mm,800mm×800mm, and so on |

Key Features & Benefits

Our laboratory filter press is designed to provide accurate, efficient, and dependable filtration for research and small-scale production settings. It was made to be durable, flexible, and easy to use, and it gives consistent results that closely mimic full-scale industrial filtration processes.

Compact and mobile design: It has a small footprint and wheels for easy movement and quick setup.

High Filtration Accuracy: Works with microfiltration, fine filtration, and experiments that need a lot of cake dryness.

Strong Construction: Housings made of stainless steel 304/316L won’t rust and will last a long time.

Easy Cleaning & Maintenance: Smooth surfaces and detachable components simplify laboratory operation.

Customization supported

We offer laboratory filter presses that can be fully customized to meet the needs of research facilities, universities, pilot plants, and small-scale manufacturers. Every unit can be customized to fit the needs of the materials, the filtration goals, and the process, making sure that it works at its best and gives accurate test results.

- Filter Plates: PP or stainless steel plates, adjustable quantity, and various plate sizes.

- Machine Materials: 304/316L stainless steel or Q345 carbon steel for different corrosion and strength needs.

- Feeding Methods: Top feed, center feed, or corner feed based on material behavior.

- Pressure & Capacity: Adjustable filtration pressure, chamber volume, and filtration area.

- Additional Systems: Optional pumps, valves, control panels, drip trays, and complete standalone filtration stations.

filter press Solution

Felxible Payment

We accept T/T, L/C at straight, PayPal, and more methods.

Quality Assurance

Quality control at every stage of the manufacturing process.

Effective Logistic

Safe and reliable logistics services covers more than 30 countries.

Customize Service

We can tailor a filter press to your specific needs.

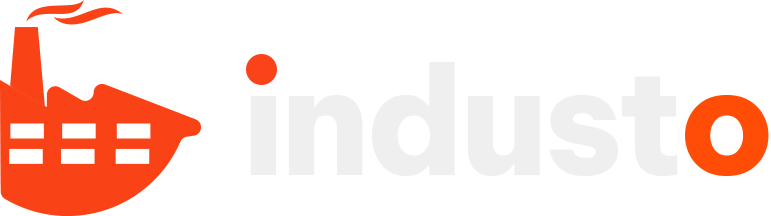

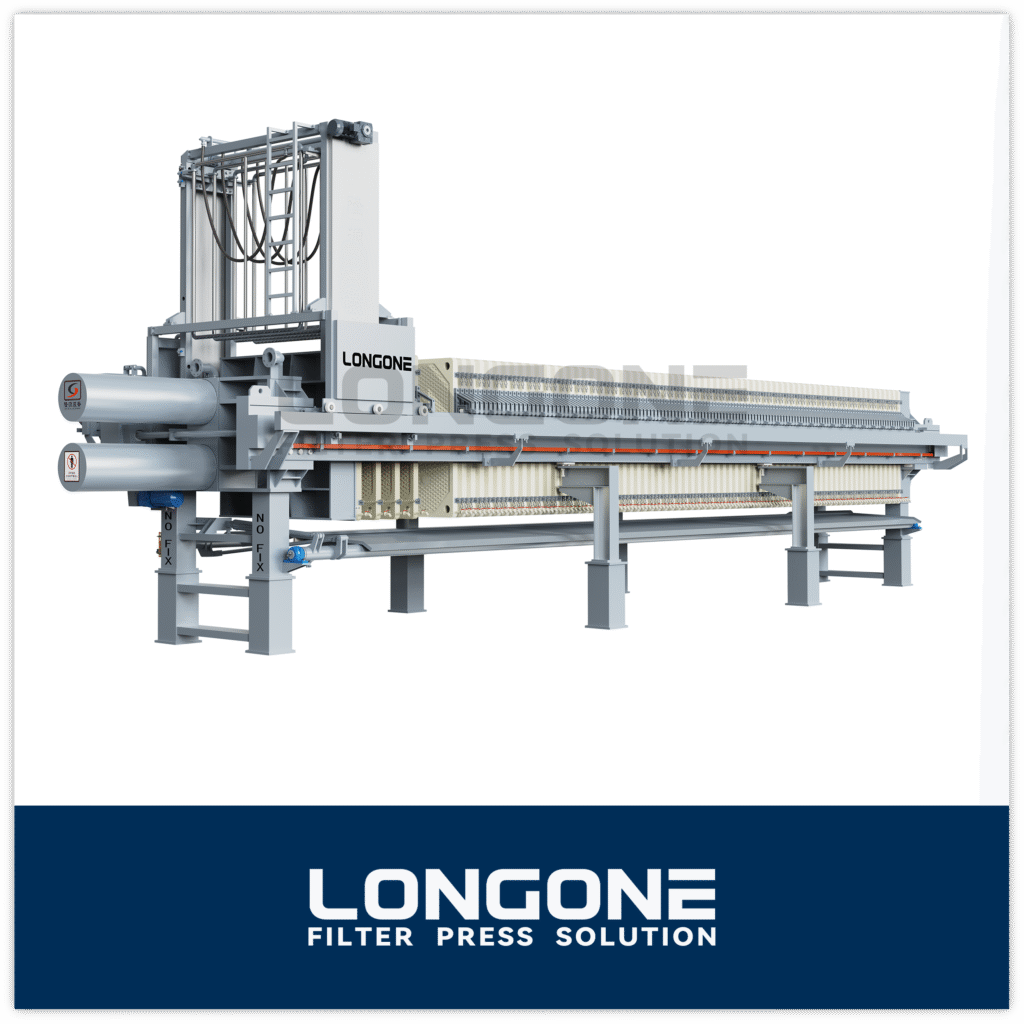

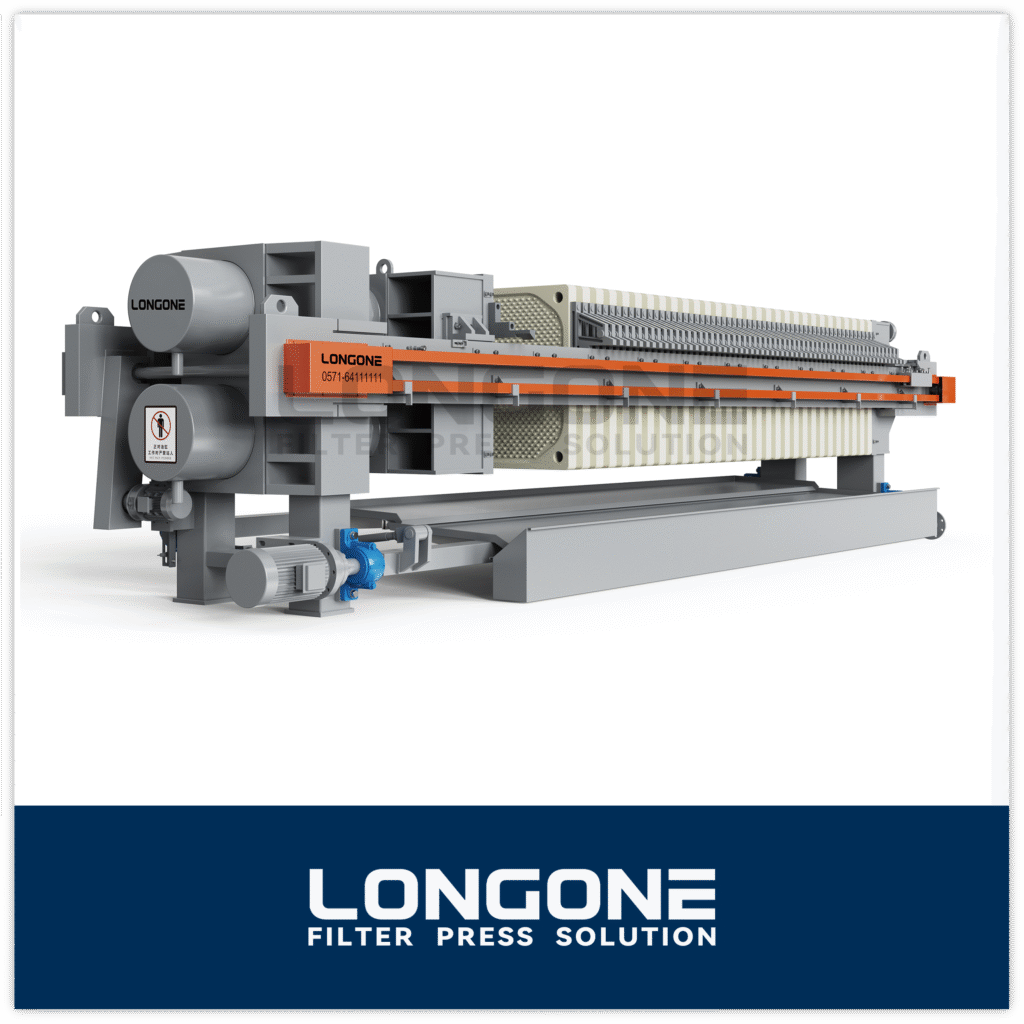

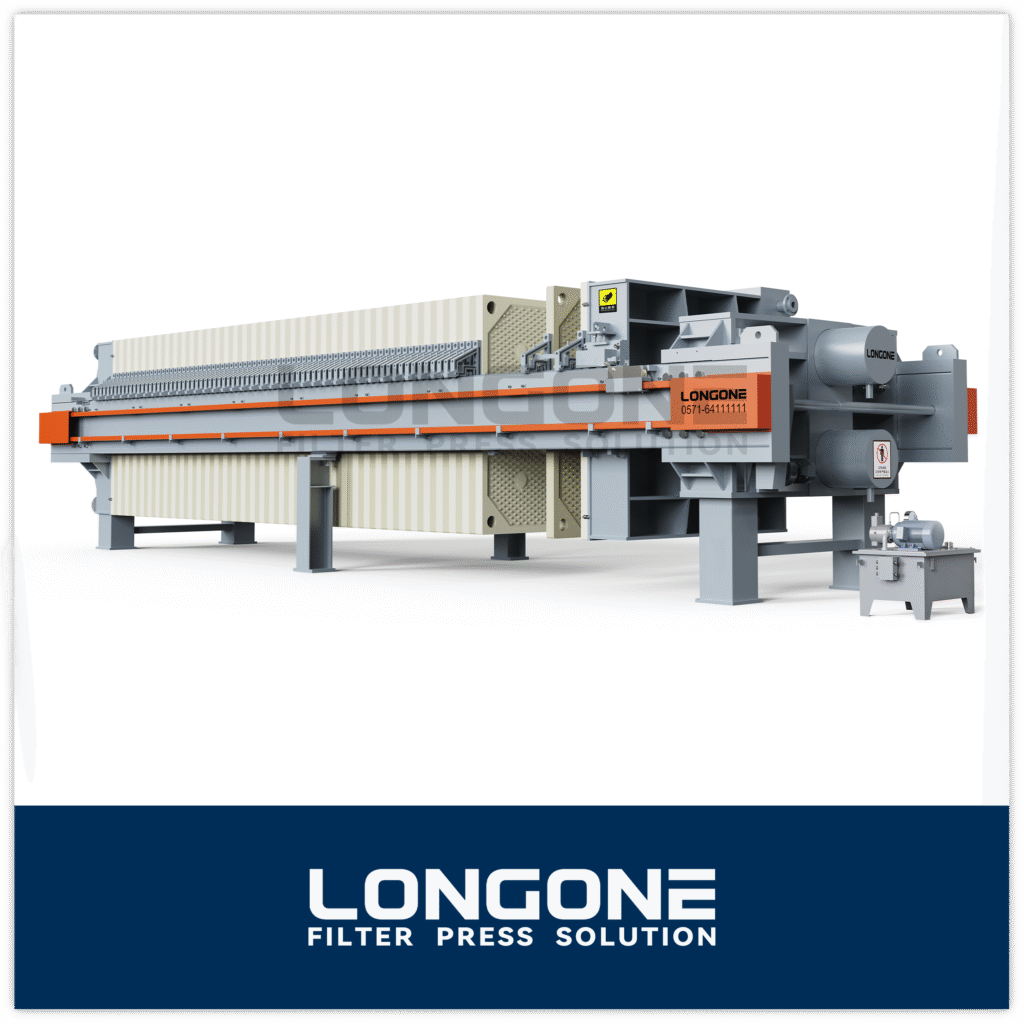

Longone Corporation is a world leader in making custom filtration solutions for a wide range of industries, including mining, minerals processing, chemicals, wastewater treatment, aggregates, and many other specialized uses. We have decades of experience separating liquids from solids, and our goal is to provide customers around the world with advanced, reliable, and efficient filtration technologies that improve their operations. Longone makes high-quality equipment for both standard and heavy-duty use. They make everything from filter presses to complete integrated filtration systems. Filter presses, filter plates, filter cloths, conveyors, and a full range of accessories made to meet the needs of different industries are all part of our product line.

Please get in touch with us if you need a reliable filtration system for your lab or business. Our engineering team is ready to help you in a way that works for you and give you professional advice.

Purpose of the Lab Filter Press

The lab filter press is made for research, testing, and small-scale production processes that need solid-liquid separation that is precise and can be repeated. It lets users study how filtration works, check how well cake forms, improve washing efficiency, and look at how well dewatering works in a controlled lab setting by copying the performance of industrial filter presses on a smaller scale. This makes it an important tool for process development, quality control, pilot testing, and feasibility studies in chemical engineering, pharmaceuticals, environmental treatment, food processing, new material research, and other scientific fields.

Shipping and Delivery

We ship all over the world and make sure that your package is safe and that the logistics are well-coordinated. We make sure that our filter presses and accessories get to your facility on time and with full tracking, export paperwork, and protection.

Related products

To meet different application needs, we also offer a full range of filtration solutions, such as the Chamber Filter Press, Frame And Plate Filter Press , Membrane Filter Press, Stainless Steel Filter Press, and Sludge Filter Press.

HQ Address

No.111 Fengxiang Road, Tonglu Economic Development Zone, Hangzhou, Zhejiang Province

Email Address

info@longonefiltra.com