Breakdowns in filter presses can stop production and quickly raise costs. Plant managers and engineers need to know about common problems and how to fix them.

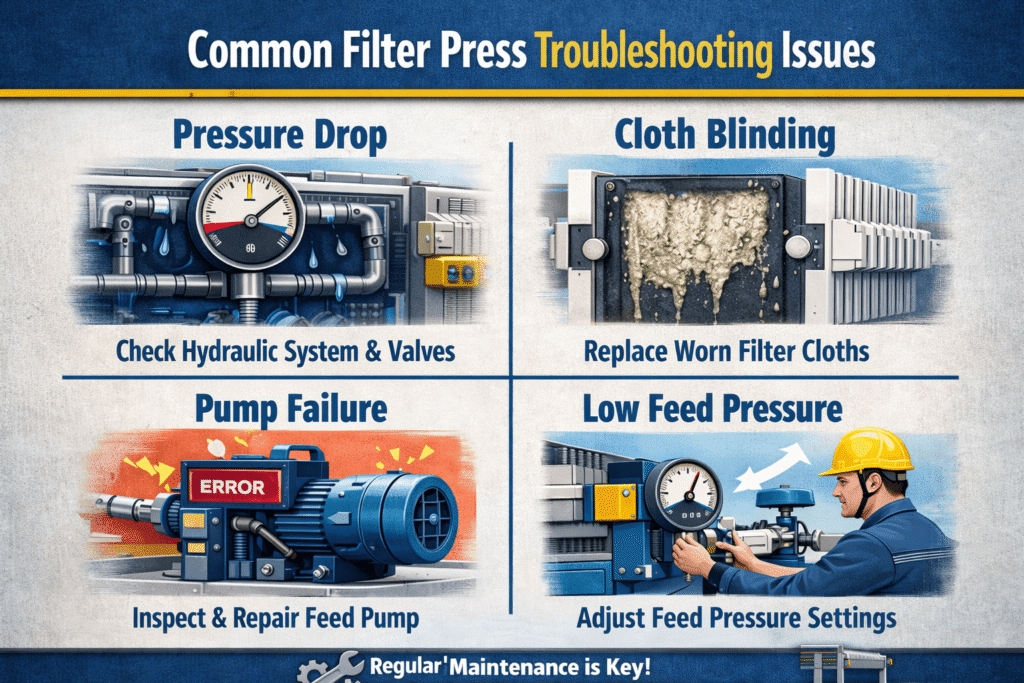

Filter press troubleshooting involves identifying issues like pressure drops, cloth blinding, or pump failure. Solutions include checking hydraulic systems, replacing worn cloths, and adjusting feed pressure. Regular maintenance is key.

Let’s look into the most common types of filter press problems and how to fix them.

Why Filter Press Troubleshooting Matters?

Even minor filter press issues can disrupt industrial operations.

Timely troubleshooting helps reduce unplanned downtime, extend equipment lifespan, and cut maintenance costs. It also ensures safety and environmental compliance by avoiding sludge leaks or equipment failures. With proper maintenance and fast diagnosis, businesses can achieve higher filtration efficiency and system stability.

Understanding filter press behavior is the first step to sustainable productivity.

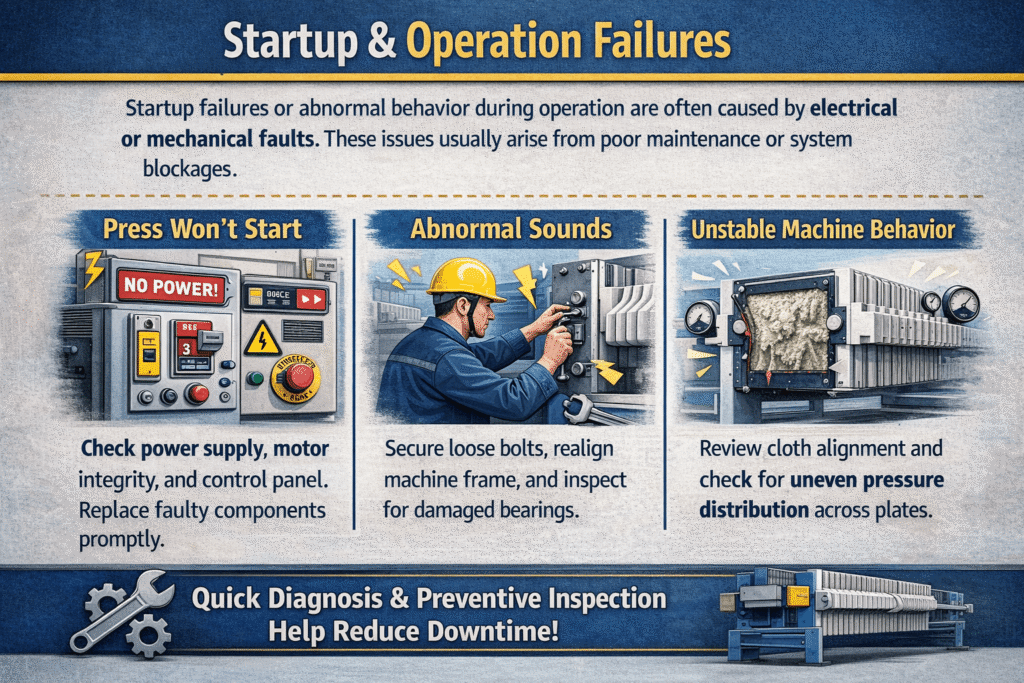

1. Startup & Operation Failures

Startup failures or abnormal behavior during operation are often caused by electrical or mechanical faults. These issues usually arise from poor maintenance or system blockages.

Common causes and solutions include:

- Press won’t start: Check power supply, motor integrity, and control panel. Replace faulty components promptly.

- Abnormal sounds during operation: Secure loose bolts, realign machine frame, and inspect for damaged bearings.

- Unstable machine behavior: Review cloth alignment and check for uneven pressure distribution across plates.

Quick diagnosis and preventive inspection help reduce downtime significantly.

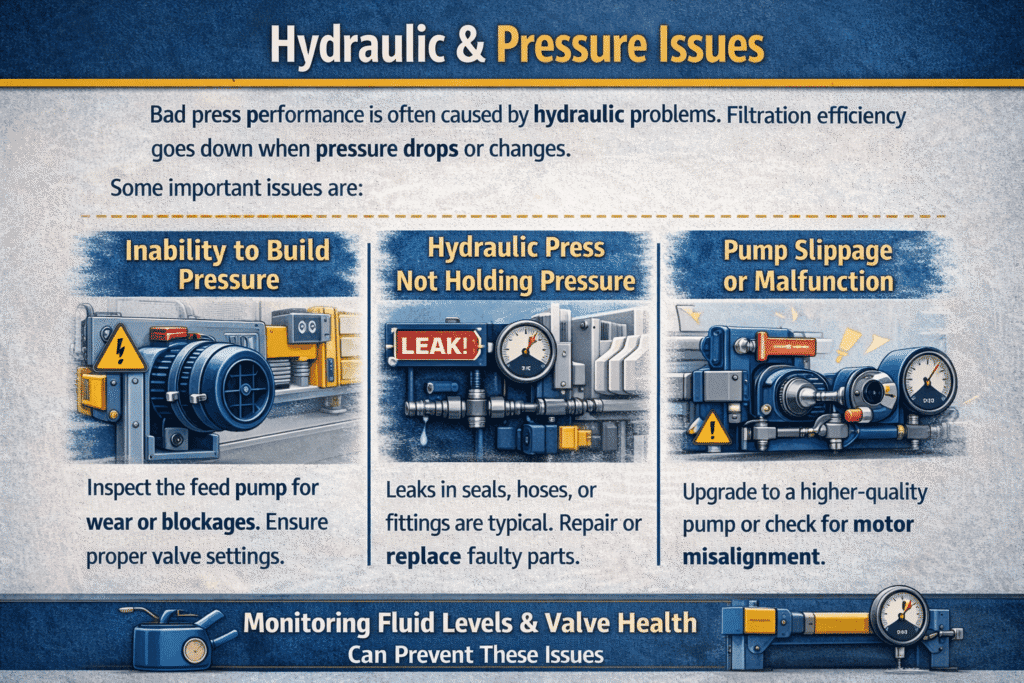

2. Hydraulic & Pressure Issues

Bad press performance is often caused by hydraulic problems. Filtration efficiency goes down when pressure drops or changes.

Some important issues are:

- Inability to build pressure: Inspect the feed pump for wear or blockages. Ensure proper valve settings.

- Hydraulic press not holding pressure: Leaks in seals, hoses, or fittings are typical. Repair or replace faulty parts.

- Pump slippage or malfunction: Upgrade to a higher-quality pump or check for motor misalignment.

Monitoring fluid levels and valve health can prevent these issues.

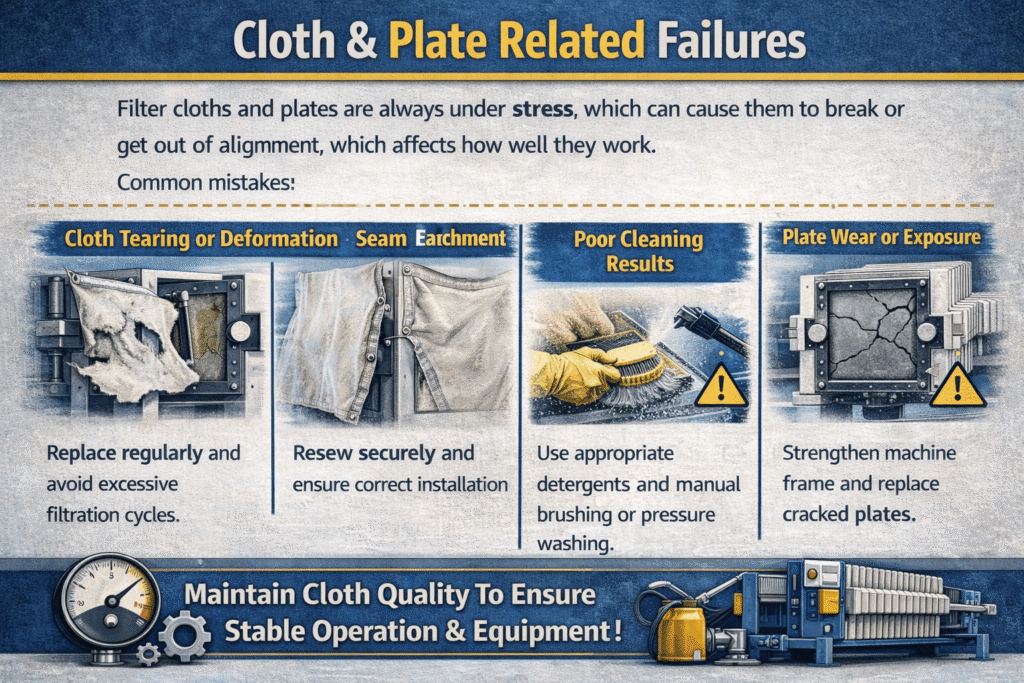

3. Cloth & Plate Related Failures

Filter cloths and plates are always under stress, which can cause them to break or get out of alignment, which affects how well they work.

Common mistakes:

- Cloth tearing or deformation: Replace regularly and avoid excessive filtration cycles.

- Seam detachment: Resew securely and ensure correct installation.

- Poor cleaning results: Use appropriate detergents and manual brushing or pressure washing.

- Plate wear or exposure: Strengthen machine frame and replace cracked plates.

Keeping the quality of the cloth is very important for stable operation and the health of the equipment over time.

4. Cake & Filtration Abnormalities

The quality of the filter cake has a direct effect on drying, disposal, and throughput. When a formation is bad, it usually means that the system or chemicals are out of balance.

The main problems are:

- Low efficiency: Check retention time, fix internal damage, and optimize slurry consistency.

- Cracking or excessive compression: Adjust press time and consider adding flocculants or binders.

- High moisture content in cake: Clean clogged cloths and ensure pressure is adequate.

Filter press optimization often requires balancing pressure, time, and feed chemistry.

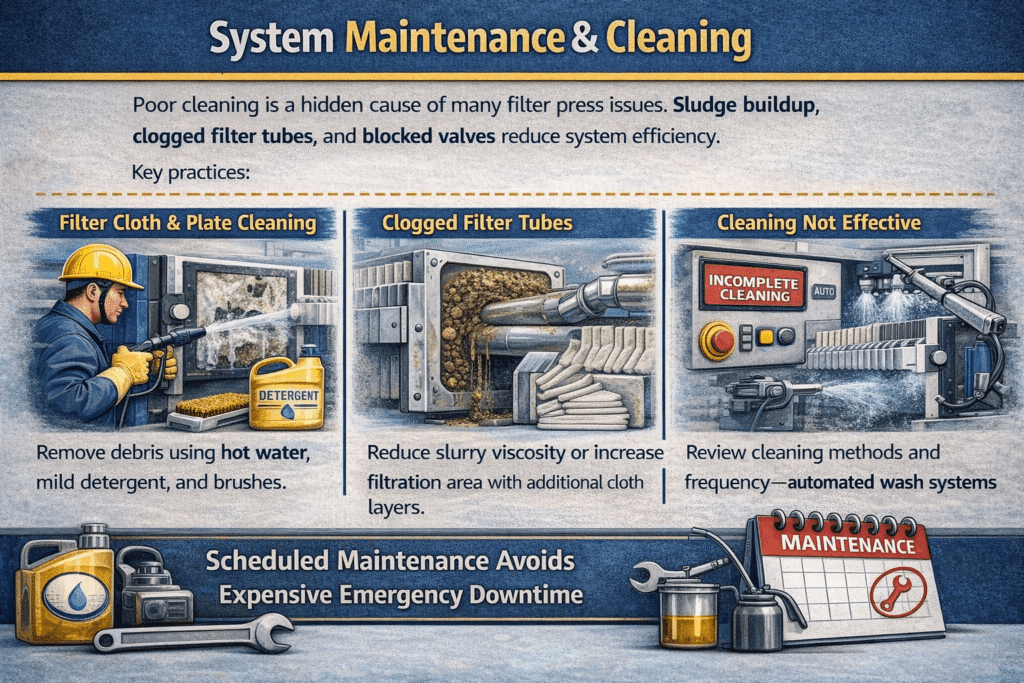

5. System Maintenance & Cleaning

Poor cleaning is a hidden cause of many filter press issues. Sludge buildup, clogged filter tubes, and blocked valves reduce system efficiency.

Key practices:

- Filter cloth and plate cleaning: Remove debris using hot water, mild detergent, and brushes.

- Clogged filter tubes: Reduce slurry viscosity or increase filtration area with additional cloth layers.

- Cleaning not effective: Review cleaning methods and frequency—automated wash systems help.

Scheduled maintenance avoids expensive emergency downtime.

6. Structural & Safety Failures

Overused or poorly built filter presses may develop structural faults, increasing safety risks and operational disruptions.

Watch for:

- Loose bolts and fasteners: Replace low-quality bolts and tighten connections regularly.

- Sludge or liquid leakage: Replace torn cloths and ensure secure connections.

- Exposed internal metal parts: Repair internal frame or cover protective surfaces.

- Burned-out motors: Reduce machine load and improve cooling systems.

Ensuring robust construction and proper installation is vital for long-term operation.

Filter Press Troubleshooting: 21 Common Issues

Here is a quick overview of frequent filter press faults, causes, and solutions:

| Issue | Possible Causes | Solutions |

|---|---|---|

| Cannot start | Power failure, motor fault, blockage, poor connection | Check power, clear blockage, inspect motor, repair connection points |

| Abnormal noise during operation | Loose metal parts, imbalance, worn bearings | Tighten bolts, rebalance machine, replace bearings |

| Low filtration efficiency | Clogged filter cloth, internal damage, insufficient filtration time | Replace cloth, repair internals, increase cycle time |

| Filter tube clogging | High slurry viscosity, small filtration area | Adjust viscosity, increase filter area |

| Unstable operation | Poor cloth performance, uneven or low pressure | Replace cloth, adjust pressure |

| Filter cloth seam detachment | Weak stitching, poor connection to frame | Reseam cloth, improve connection |

| Low filtration pressure | Poor-quality pump, slow pump speed | Upgrade pump, increase pump speed |

| Filter cloth wear or tear | Long usage, physical damage | Replace cloth, repair internal parts |

| Cake cracking | Loose cake structure, overloaded machine | Increase pressure, add binding agents |

| Poor cloth cleaning | Incomplete washing, incorrect handling | Improve cleaning quality, adjust method |

| Pump slippage | Pump malfunction, damaged machine parts | Replace pump, inspect internal components |

| Cloth deformation | Excessive cycle time, poor maintenance | Improve maintenance, replace cloth regularly |

| High moisture in cake | Low pressure, insufficient filtration area | Increase pressure, expand filtration area |

| Sludge or liquid leakage | Loose cloth connection, cloth damage | Adjust or replace cloth and sealing areas |

| Motor burnout | Overload, excessive internal heat | Reduce load, check internal cooling |

| Machine leakage | Wear and tear, weak structural components | Reinforce protection, improve structure |

| Filter tube cannot be cleaned | Long filtration time, component damage | Clean regularly, repair tube parts |

| Loose bolts | Overuse, poor-quality fasteners | Replace bolts, strengthen structure |

| Cake breaks easily | Poor plate design, short filtration time | Redesign plates, increase cycle time |

| Over-compressed cake | Excessive press time, high cake viscosity | Stop pressing on time, add lubricants |

| Exposed metal parts | Internal damage, improper handling | Repair parts, improve handling procedure |

Conclusion

Routine inspection and proactive maintenance are essential for avoiding filter press faults.

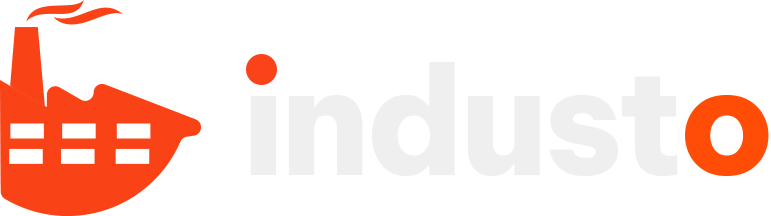

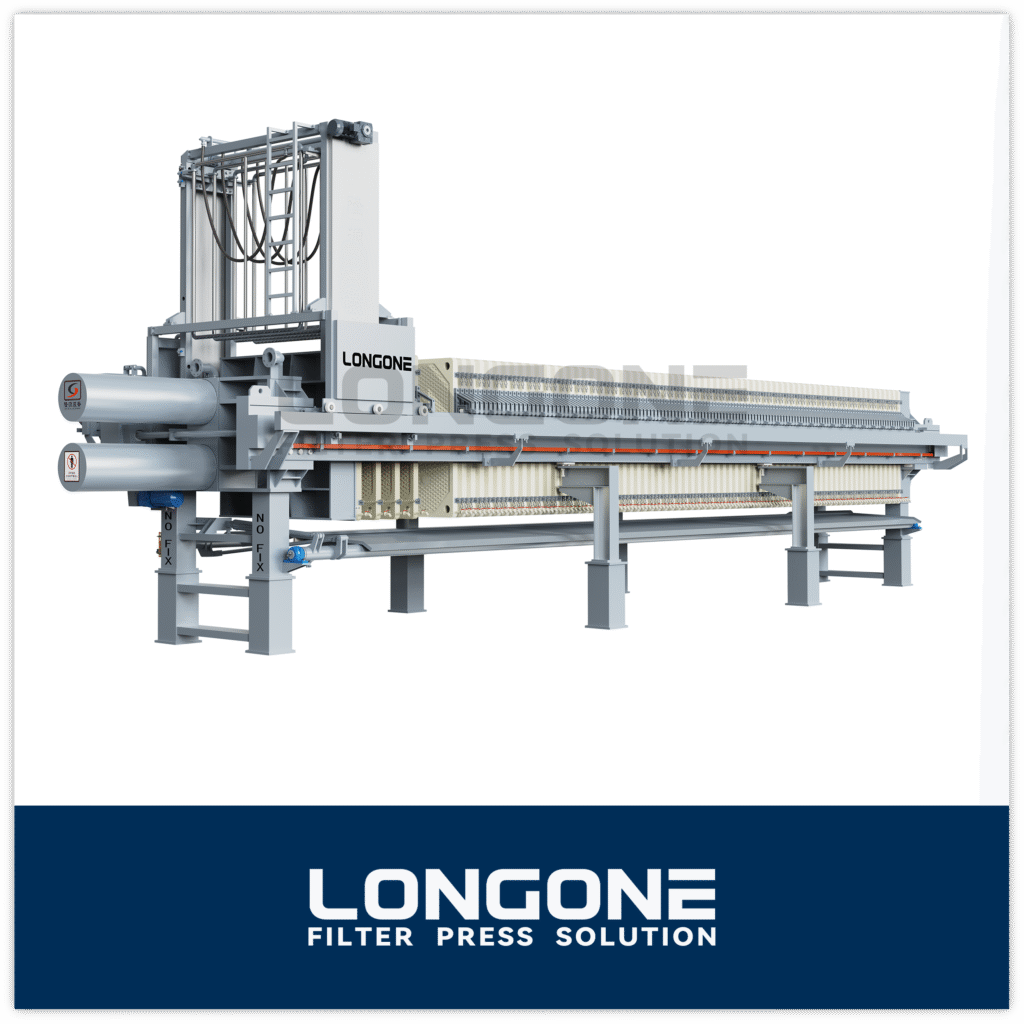

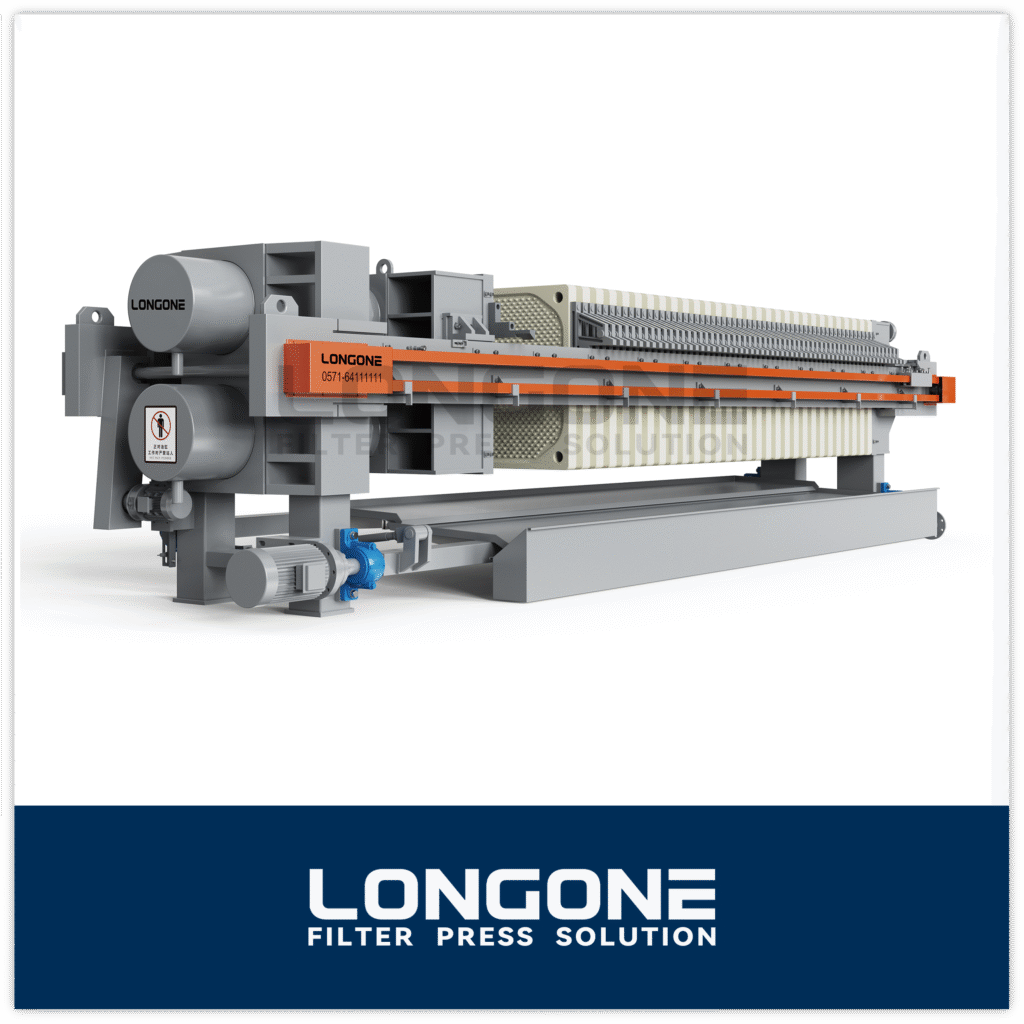

For reliable, customizable, and durable filter press systems, Longone offers industry-proven solutions tailored for industrial and municipal needs.

FAQ

Why is my hydraulic press not holding pressure?

Hydraulic leaks—especially around seals and hoses—are often the culprit. Check the relief valve and pump for wear.

Why is my water filtration system not working?

Look for blocked filters, aged media, or backwash systems failing to operate correctly.

How to clean a filter press?

Remove filter plates, brush out residue, and flush the system with hot water to remove sediment and syrup buildup.