Many filter press failures stem from overlooked operational details.

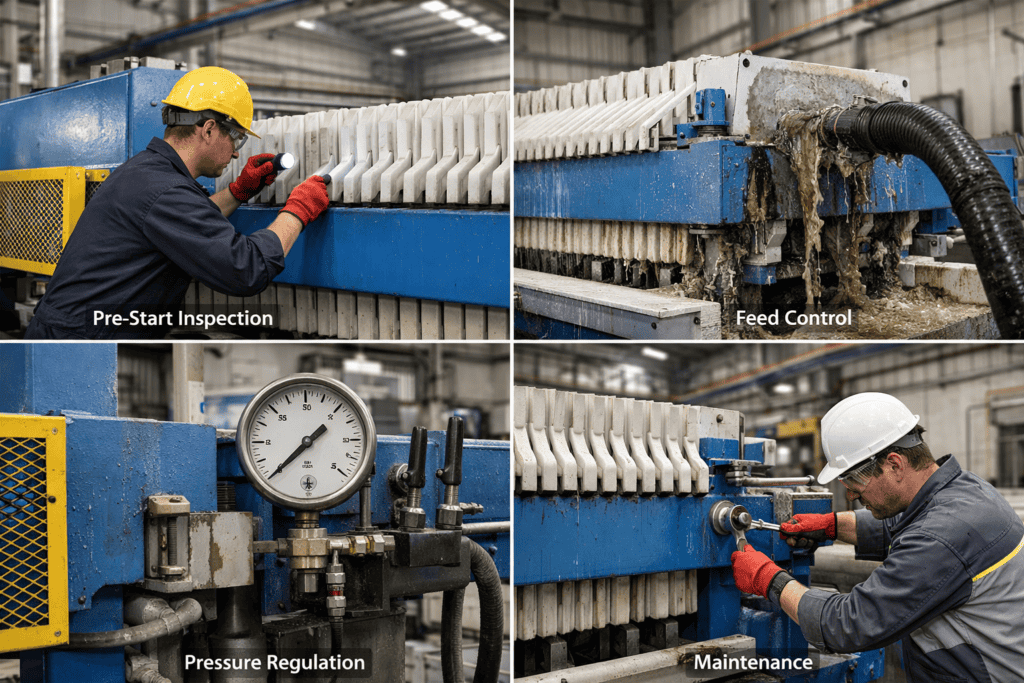

Filter press operation involves key stages: pre-start inspection, feed control, pressure regulation, and maintenance. Each step ensures efficient dewatering, reduced downtime, and extended equipment lifespan.

Let’s walk through each stage in detail.

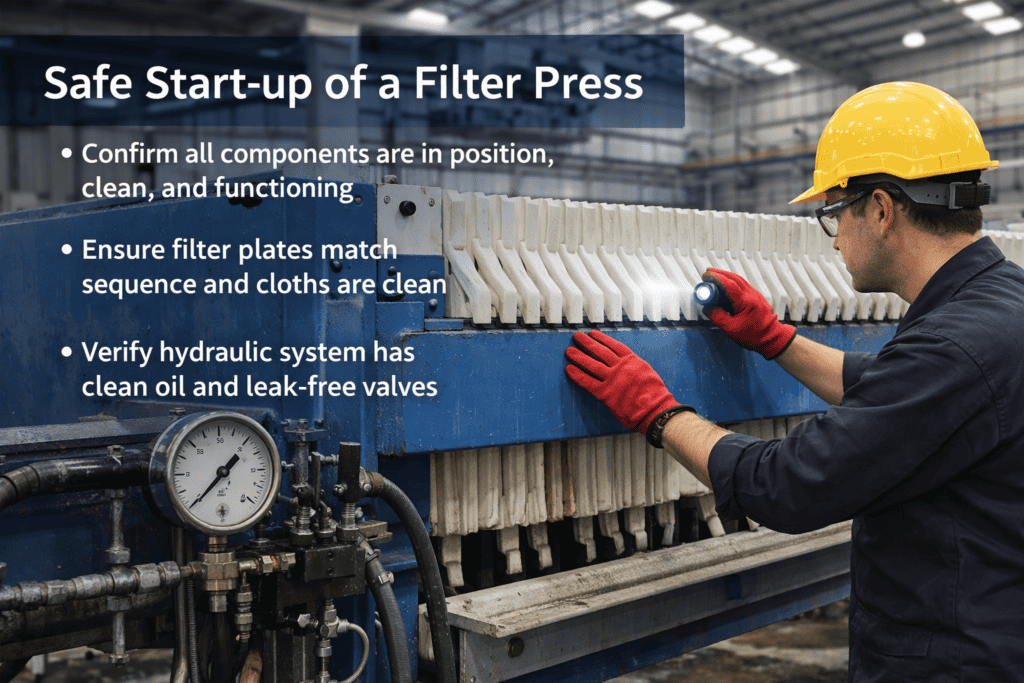

How to Ensure Safe Start-up of a Filter Press?

Proper start-up procedures are critical to avoiding mechanical failures, leaks, or safety hazards during operation.

Before powering on, operators should perform a systematic inspection, covering mechanical alignment, hydraulic integrity, and component cleanliness. The following checklist ensures a safe and reliable start-up:

1. Filter Plate & Membrane Check:

Count and inspect all filter plates or membrane plates. They should be intact, flat (no warping), and arranged in the correct sequence. Plates must face the correct direction and fit tightly to avoid filtration gaps or slurry bypass.

2. Plate Alignment and Repositioning:

All plates should be pushed towards the stop plate side. Ensure they are aligned along the guide rails without tilting or overlap. Misaligned plates can cause uneven pressure, cracked plates, or hydraulic overloading.

3. Filter Cloth Installation Inspection:

Check that each filter cloth is installed without wrinkles, damage, or slack. Cloths should lay flat with their sealing edges tightly seated on the plate face. Improper installation leads to leakage or incomplete sealing.

4. Hydraulic System Check:

Confirm oil level is within the safe range.

Oil should be clean (no cloudiness, bubbles, or foreign particles).

Verify that the oil pump and return system operate smoothly.

Pressure gauge must display stable readings when idle.

5. Valve and Pipeline System Review:

Inspect all valves on feed, filtrate, and return pipelines:

Open and close each valve manually to ensure smooth operation.

Confirm no residual pressure in pipelines.

Check joints for signs of leakage or corrosion.

6. Safety Device Test:

Confirm that all emergency stop switches and limit sensors are functioning. Safety light indicators, alarms, and interlocks should also be tested before production begins.

Common mistakes to avoid during start-up:

- Skipping plate alignment checks.

- Starting the pump without checking oil levels.

- Using damaged filter cloths or running without them.

- Bypassing safety sensors to “save time”.

A well-prepared start-up not only protects the equipment but also prevents costly delays.

What Are the Key Operational Tips During Filter Press Operation?

Different materials require specific feed strategies to achieve optimal results.

To ensure consistent performance, operators must understand how to adjust pressure, flow, and sequence based on slurry characteristics. For instance, newly installed filter cloths may cause leakage due to open pores. Two effective solutions are:

- Pressure-Controlled Feed with Return Flow: Start with low feed pressure and open return valves to prevent high-pressure impact. Once the filtrate runs clear, gradually close return lines and increase pressure.

- Filter Cake Sealing: Apply a small amount of clean filter cake along the cloth edges to create a temporary seal. This method is especially useful during initial runs with new cloths.

For slurries that drain quickly, like coal slurry or quartz sand, use segmented feeding. To fill the chamber all the way from the far end, close the filtrate valves near the feed end for a short time. Open the closed valves slowly, one at a time, and stop between each one to keep the flow and pressure even.

When working with slurries with a low solid concentration (less than 10%), a double-end feed method can cut down on fill time and increase throughput by a lot. To avoid putting stress on the structure, make sure that both pumps have the same flow and pressure.

To run a filter press efficiently, you need to know how feed works.

How to Handle Common Filter Press Failures?

Beam deformation is one of the most common but often misunderstood issues.

Over time, filter press beams may bend due to repeated high pressure or uneven loading. First, determine whether the deformation is elastic (reversible) or plastic (permanent).

- Elastic Deformation: Rearrange filter plates toward the inner curve of the bent beam, then apply moderate pressure (within 80% of rated pressure). Maintain pressure for 10–15 minutes to gradually restore beam shape.

- Plastic Deformation: Use jacks to apply counter-force. Monitor deformation recovery using gauges and avoid overcorrection. After any correction, inspect for cracks or fatigue. Conduct at least two empty test cycles before returning to production.

Timely diagnosis and correction can prevent costly equipment downtime.

How to Select the Right Filter Press Size and Parameters?

Wrong sizing leads to inefficient operation and poor dewatering performance.

To calculate the required chamber volume, use the formula:

Chamber Volume (m³) ≈ (Pump Flow Rate × Slurry Concentration) ÷ Final Cake Solid Percentage

For example, with a pump rate of 10 m³/h, slurry at 30% solids, and aiming for 60% cake dryness, the estimated volume needed would be:

10 × 0.3 ÷ 0.6 = 5 m³

Also, to estimate daily dry sludge output under typical conditions:

Dry Cake Output (t) = Pump Flow × 3h × Slurry Solid % × 0.5 (Pressure Reduction Coefficient)

The coefficient adjusts for reduced effective flow as pressure builds up during operation. For viscous materials like sludge, use 0.3–0.4; for free-draining materials like sand, 0.6–0.7 may apply.

These calculations provide a reliable starting point for filter press selection.

What Are Common Operational Mistakes and How to Maintain Your Filter Press?

Many filter press problems originate from minor oversight. Here’s a breakdown of the most frequent errors and how to avoid them:

Common Operational Mistakes

| Mistake | Consequence | Correct Practice |

|---|---|---|

| Applying full pressure too early | Filter plate damage, cloth failure, risk of explosion | Start with low pressure, increase gradually after chamber fill |

| Ignoring filter cloth condition | Leakage, poor filtration, reduced cloth life | Inspect and replace worn or damaged cloths before each shift |

| Using unfiltered hydraulic oil | Wear on seals and pumps, system breakdown | Use filtered oil, change regularly, inspect seals every 3 months |

| Skipping plate alignment | Uneven pressure, plate cracking, beam deformation | Reposition plates evenly before every cycle |

| Running with a deformed beam | Structural damage, poor sealing, safety risks | Stop operation, inspect deformation type, proceed with correction |

| Poor pipeline maintenance | Leakage, reduced pressure, contamination | Regularly clean and check all valves and joints |

Filter Press Maintenance Checklist

1. Filter Cloth Cleaning:

Wash with clean water after each cycle. For clogged cloths, use high-pressure backwashing or soak with mild acid/base solutions (depending on slurry type).

2. Hydraulic System Care:

Inspect hoses and connectors for leaks.

Replace oil every 3–6 months or when contamination is found.

Clean hydraulic tank sediment quarterly.

3. Guide Rail & Roller Lubrication:

Apply industrial grease to rails and rollers every week. Ensure no misalignment, rust, or grinding noise.

4. Electrical System Maintenance:

Check terminal connections in control cabinets.

Clean dust from internal circuits to prevent overheating.

Test emergency stops and alarms monthly.

Regular maintenance extends the life of your filter press and minimizes downtime.

Conclusion

While technical specifications are important, it is the real-world filter press operation that determines long-term performance. A well-maintained, properly operated filter press reduces waste, improves output quality, and lowers operational costs.

By mastering start-up checks, adjusting for material types, preventing beam deformation, and following maintenance best practices, operators can keep their systems running efficiently—even under harsh conditions.

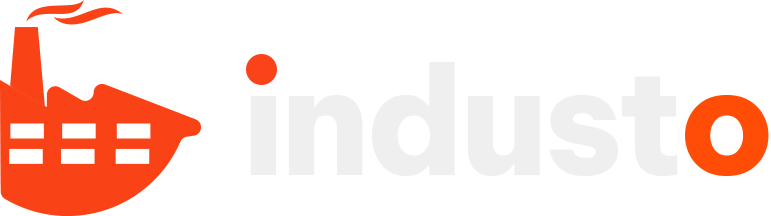

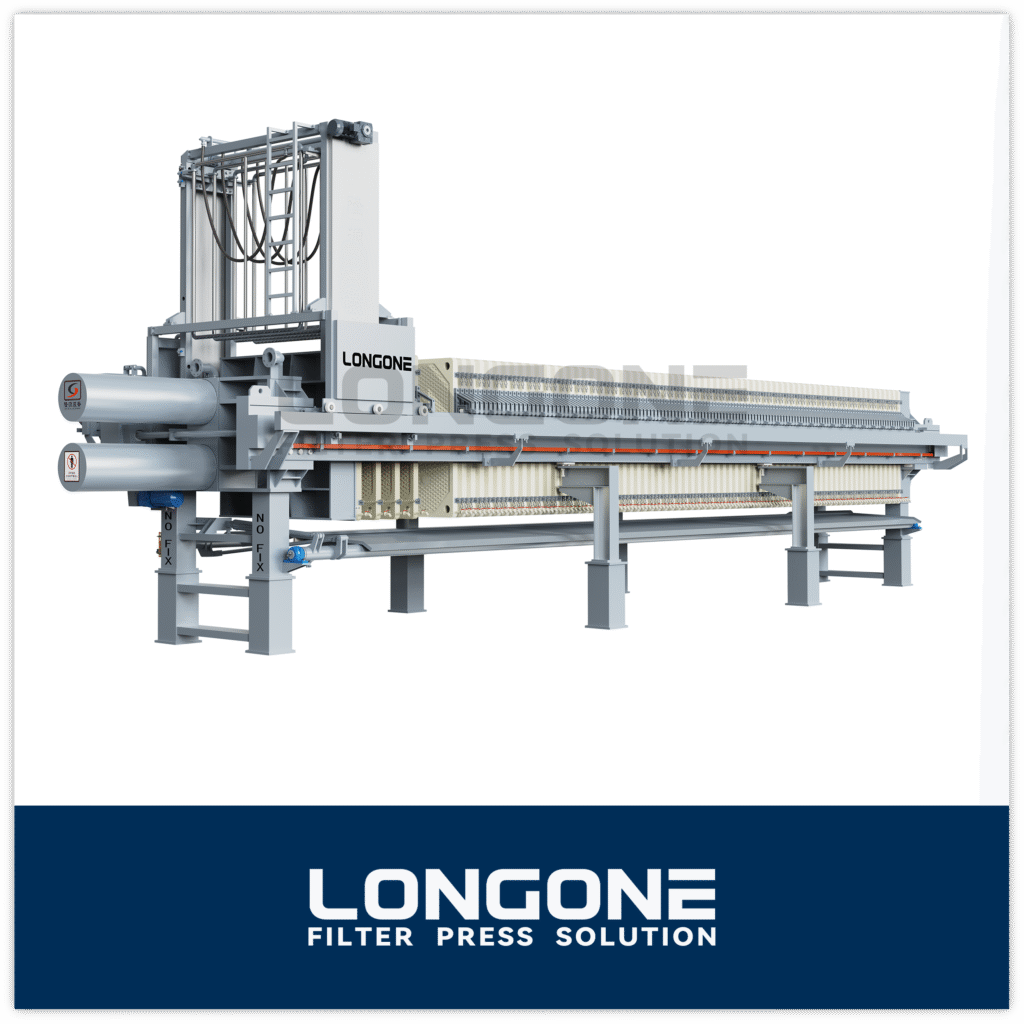

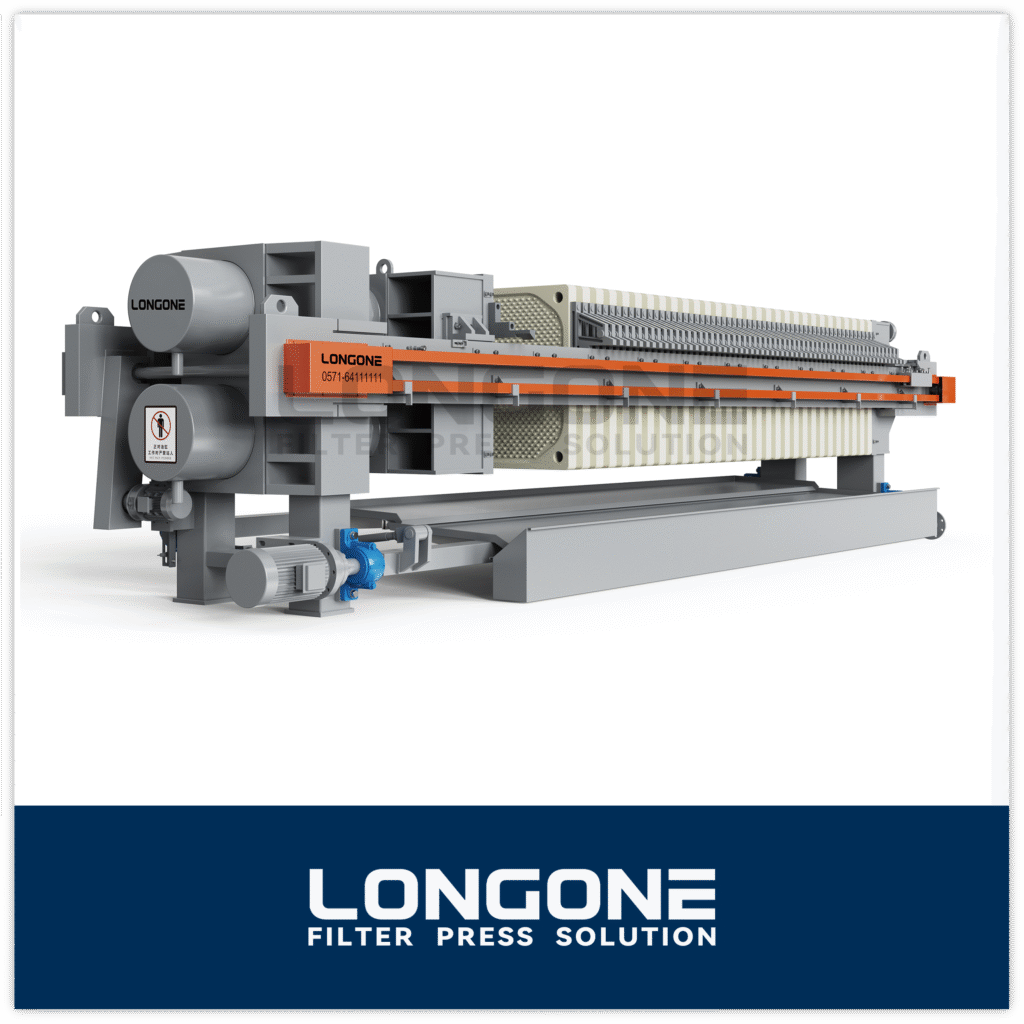

Looking for optimized filtration solutions or remote operation support? Contact Longone’s technical team today to find out how our customized filter presses can help your business.