Filter Press Manufacturer in China

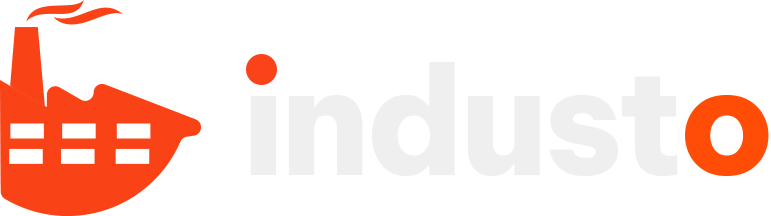

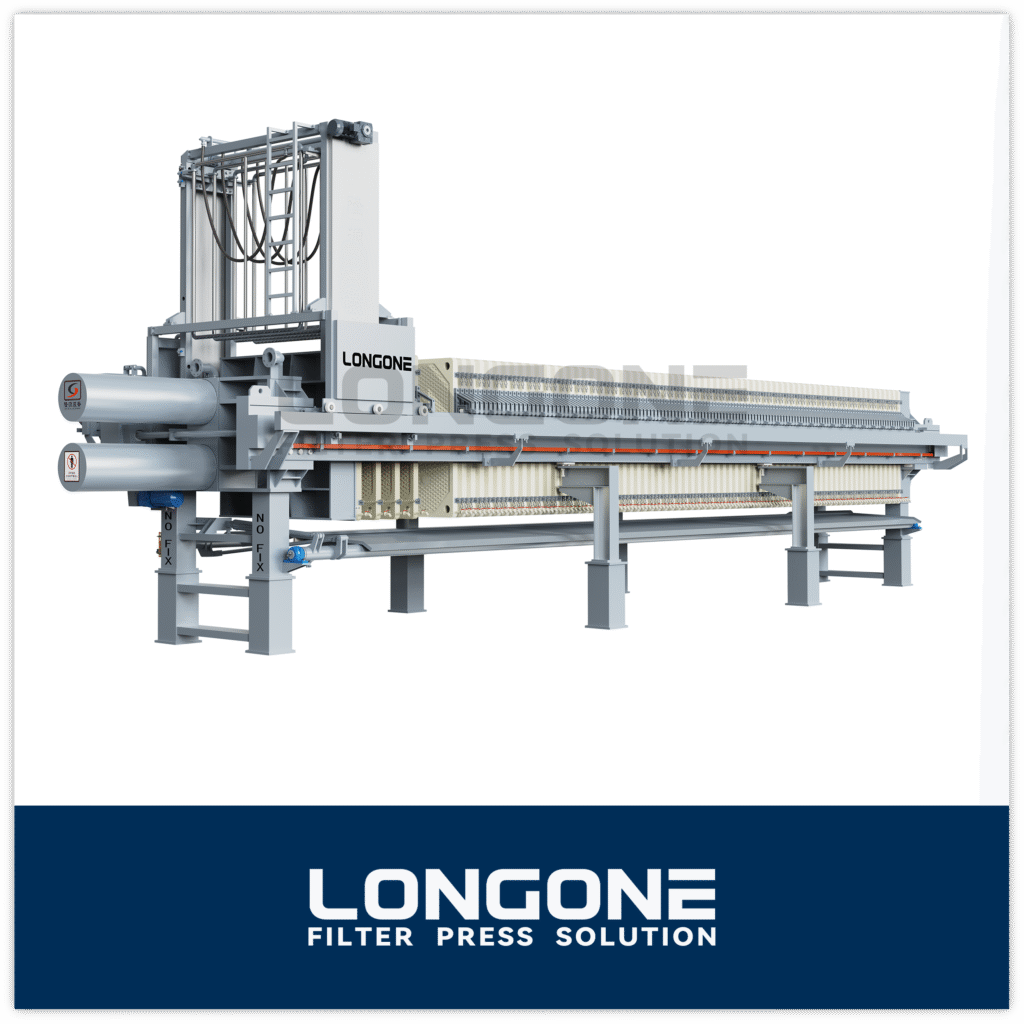

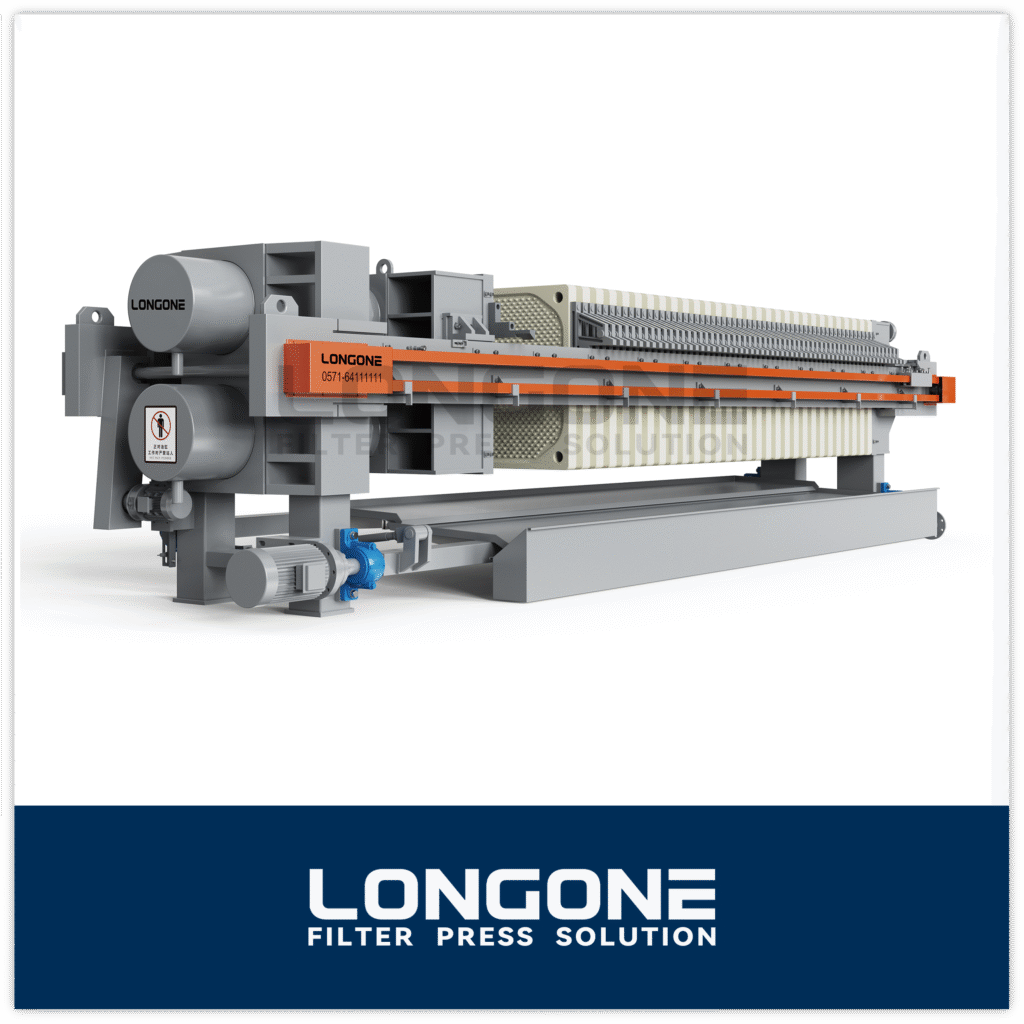

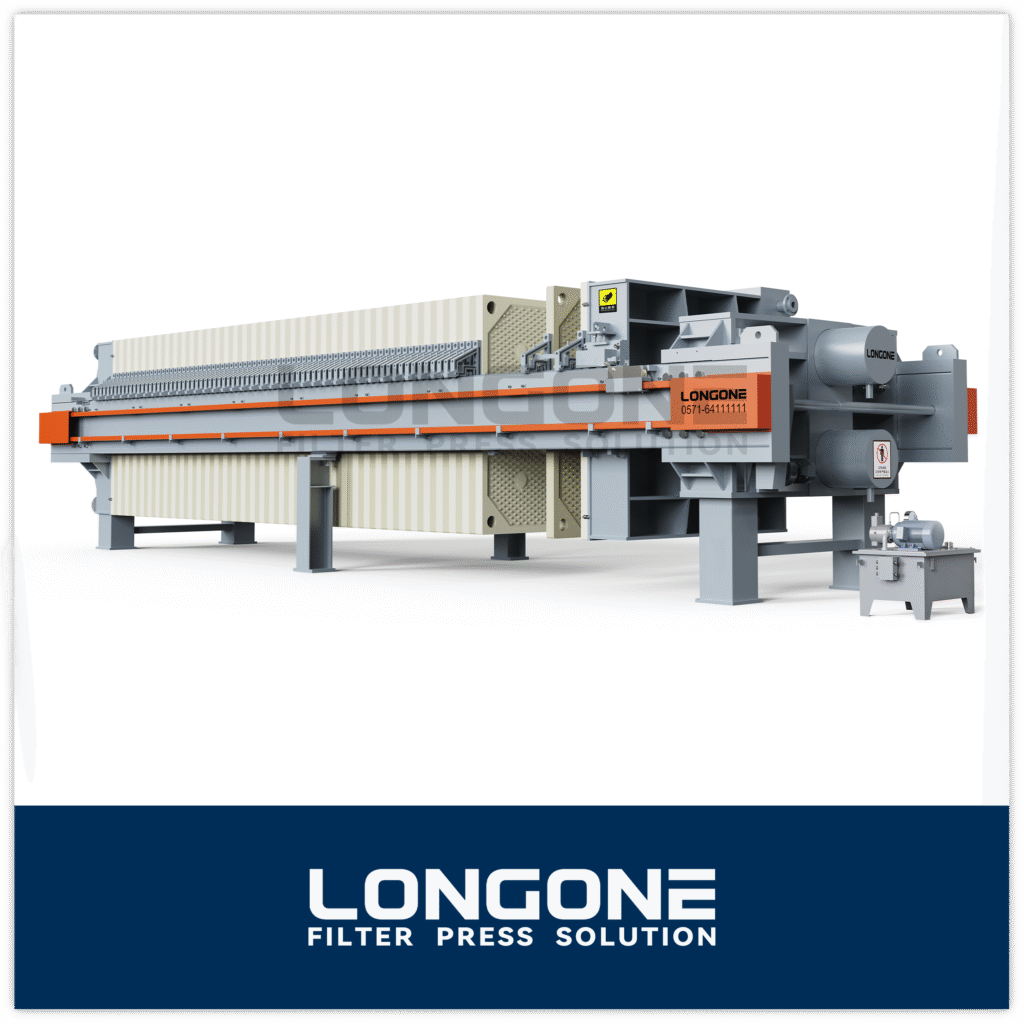

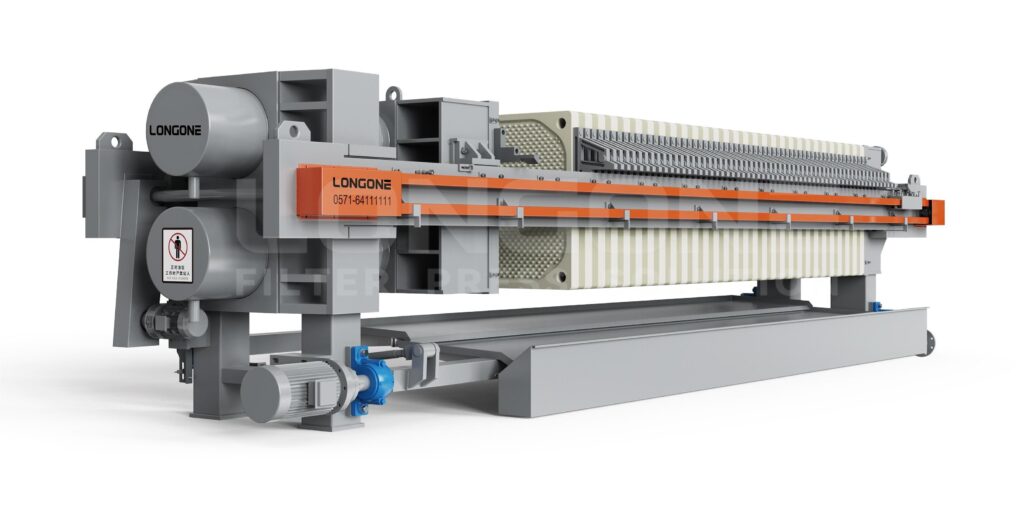

Longone is a leading filter press filter press supplier in China , specializing in advanced liquid-solid separation equipment and engineered filtration solutions.We design and build filter presses that work very well for chemical processing, mining, wastewater treatment, food and drink, steel mills, and many other industries. We sell membrane filter presses, chamber filter presses, plate and frame units, stainless steel models, laboratory presses, and full filtration systems.

Longone also offers custom filtration design, on-site technical support, installation, commissioning, spare parts supply, and emergency service support, all with a team of experienced filtration engineers. We offer reliable and long-lasting solutions that are tailored to your plant’s needs, whether you need high-pressure dewatering, dry filter cakes or a fully automated filtration line.

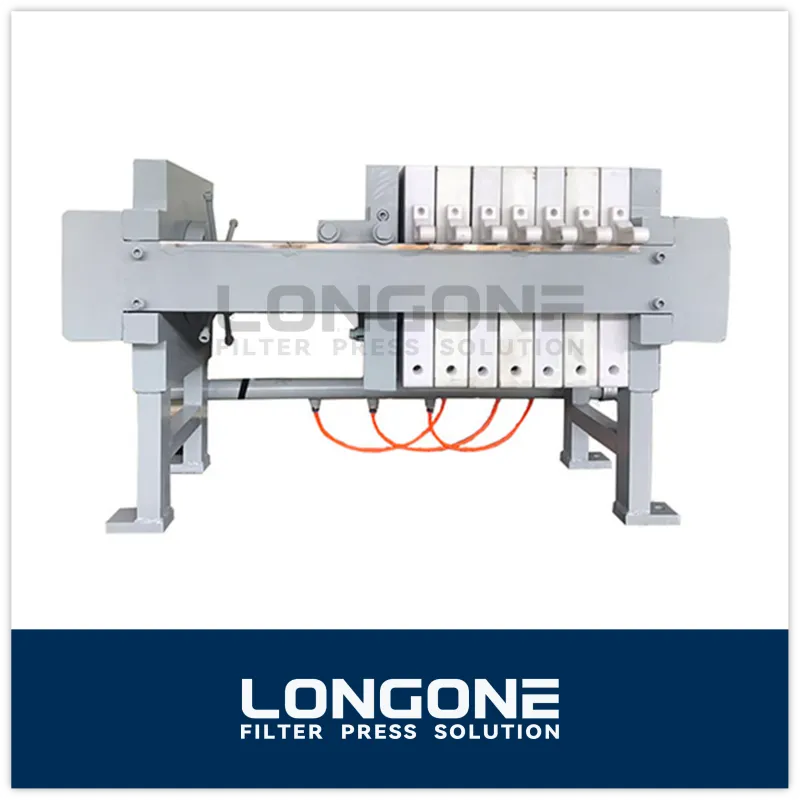

Types of Filter Press

Longone offers a wide range of filter press machine types designed for different solid–liquid separation needs. Our product lineup includes membrane, chamber, plate and frame, stainless steel, and sludge filter presses, each engineered to deliver reliable performance, high efficiency, and long service life across various industries.

Custom Filter Press Solutions

Longone makes filter press solutions that are completely tailored to the technical needs and production goals of your plant. Our engineers make systems that improve the efficiency of filtration, automation, and long-term dependability.

Customization Options Include:

- Overall System Design: Complete filtration lines engineered to match process conditions.

- Filter Capacity: Adjustable chamber volume and processing throughput.

- Filter Plate Size: Multiple plate dimensions for different pressure and cake thickness needs.

- Materials of Construction: Carbon steel, stainless steel, or corrosion-resistant materials.

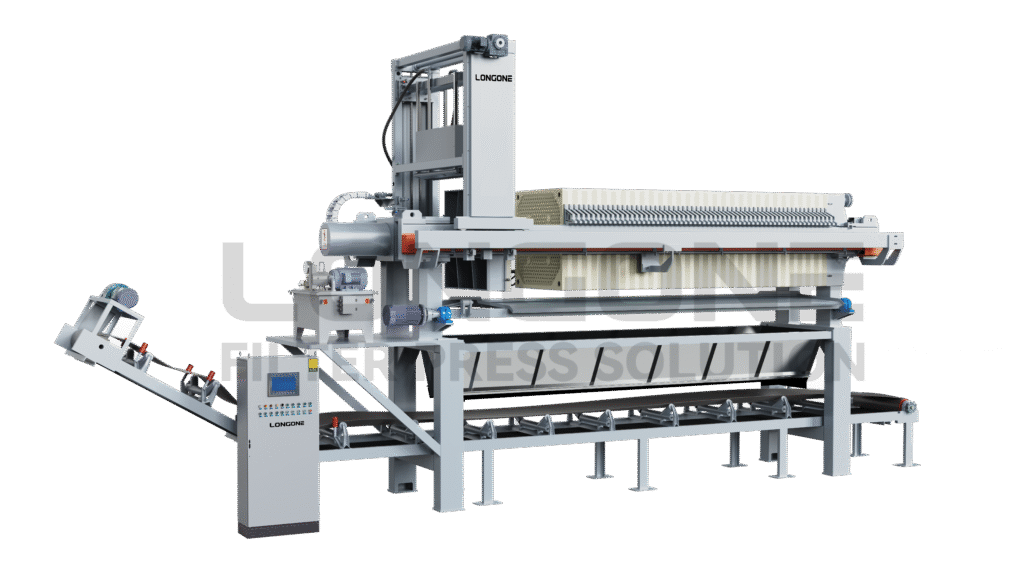

- Automation Level: Manual, semi-automatic, or fully automated control systems.

Features & Benefits

Longone filter press machines are made to separate solids and liquids quickly, reliably, and at a low cost for tough industrial uses. Our equipment is built to last, can handle high pressure, and is easy to use, all of which help it work consistently. Some of the main benefits are shorter filtration cycles, less moisture in filter cakes, and lower operating costs. Longone presses have long service lives, require little maintenance, and are very energy efficient. They have advanced automation options, durable filter plates, and optimised hydraulic systems. These benefits make our systems perfect for projects that need to treat a lot of wastewater or sludge all the time.

Why Choose Us

Choosing Longone means partnering with a trusted filtration specialist committed to delivering high-performance and long-lasting filter press solutions. We combine advanced engineering, strict quality control, and comprehensive service to support every stage of your project.

- Expert Engineering Team: Decades of experience in industrial filtration and sludge dewatering.

- High-Quality Manufacturing: Durable structures, precision components, and optimized filtration efficiency.

- Complete Product Range: From filter presses to plates, cloths, pumps, and spare parts.

- Tailored Solutions: Customized designs that match your process, capacity, and automation needs.

- Reliable Service Support: Installation, commissioning, training, maintenance, and emergency repair.

Filter Plate Options

Longone supplies high-quality filter plates engineered for durability, high pressure, and optimal cake formation. We offer membrane plates, chamber plates, and CGR plates to match different filtration requirements and ensure consistent, efficient solid–liquid separation performance.

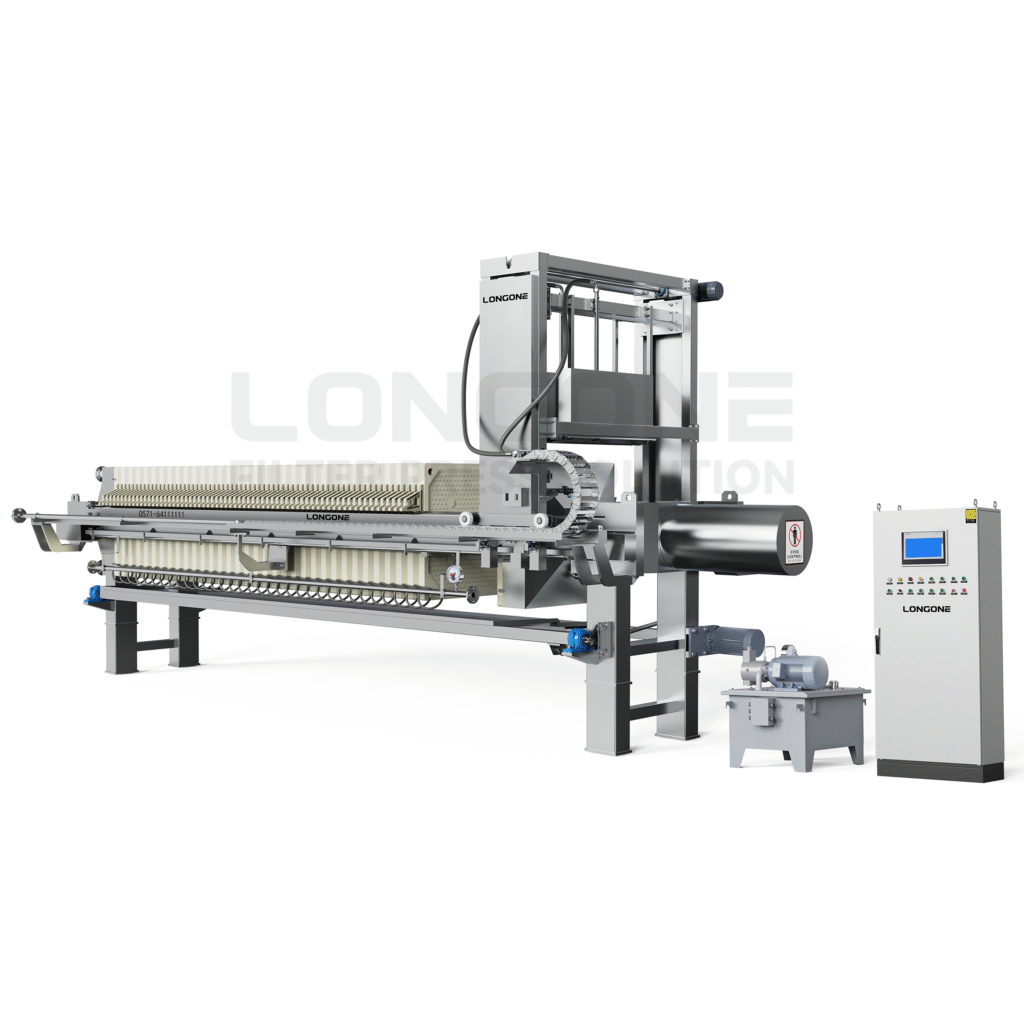

Main Components of a Filter Press

To separate solids from liquids quickly and effectively, a filter press machine has a number of important parts that work together. Longone thinks about how long each part will last, how stable it will be under pressure, and how easy it will be to fix when it breaks.

Key Components Include:

- Frame: Provides structural strength and supports all operating parts.

- Filter Plates: Form the filtration chambers and determine cake thickness and efficiency.

- Filter Cloths: Essential for capturing solids and ensuring smooth filtration flow.

- Hydraulic System: Applies closing force to seal plates and maintain operating pressure.

- Piping & Manifold: Controls slurry feeding, filtrate discharge, and drainage paths.

Applications of filter presses

Longone filter press machines are used a lot in both industry and government. They do a great job of separating solids from liquids and getting rid of sludge. Our equipment can handle a wide range of tasks and works reliably under high pressure.

Key Application Areas Include:

- Chemical Industry: Filtration of pigments, catalysts, fine chemicals, and process liquids.

- Mining & Mineral Processing: Dewatering tailings and mineral concentrates.

- Municipal Wastewater Treatment: Sludge thickening and high-dryness cake production.

- Food & Beverage: Purification of edible oils, juices, and food additives.

- Pharmaceuticals: High-purity filtration for APIs, intermediates, and biotech processes.

- Steel Mills & Metalworking: Treating oily wastewater and metal sludge.

Welcome to visit our factory

We sincerely welcome every customer to visit our factory for exchange and discussion. Please contact our staff via the button below, and we will arrange a visit for you as soon as possible.

Shipping and Delivery

We ship all over the world and make sure that your package is safe and that the logistics are well-coordinated. We make sure that our filter presses and accessories get to your facility on time and with full tracking, export paperwork, and protection.

Trade Exhibitions

Longone goes to global industry trade shows to show off our filtration technologies and talk to customers from all over the world. We show off new ideas, share our knowledge, and strengthen partnerships across many industries at these events.

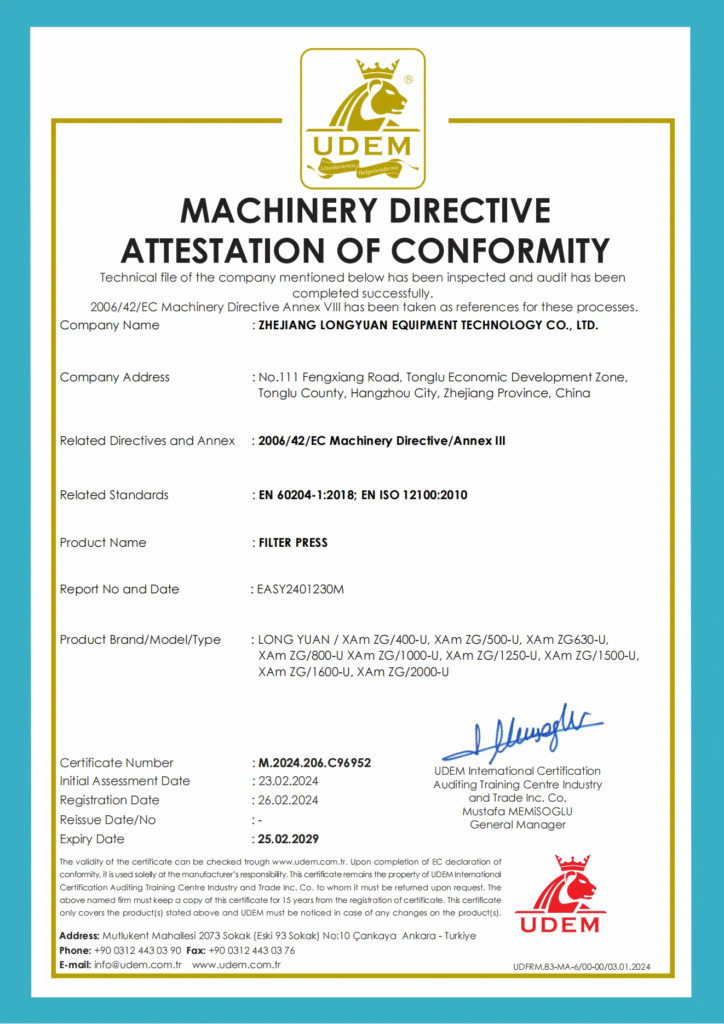

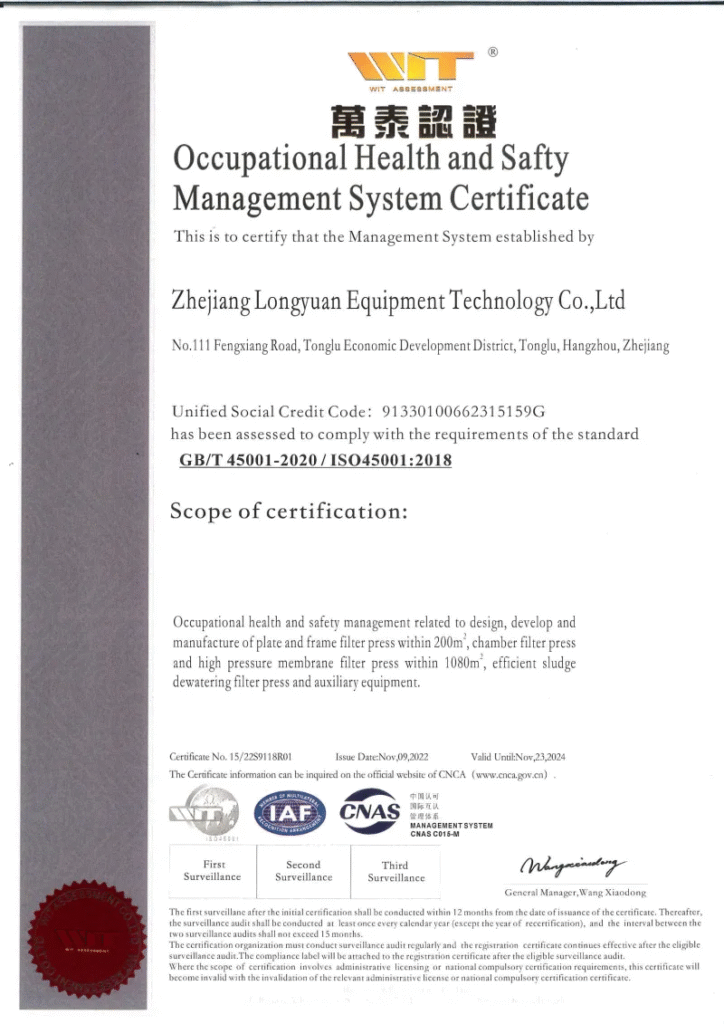

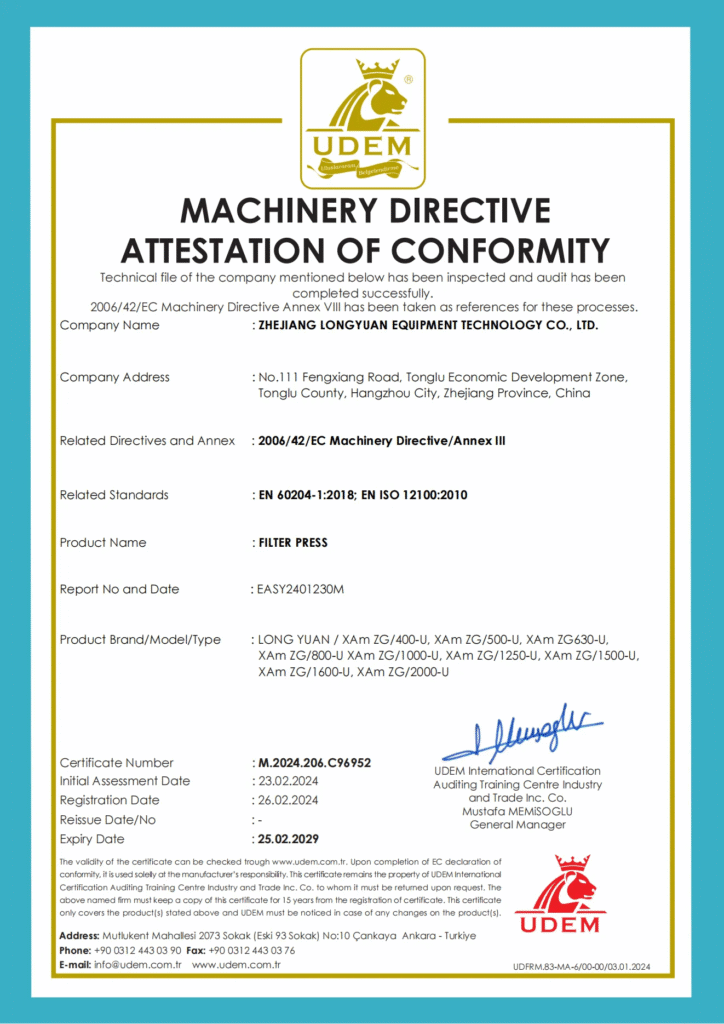

Our Certifications

Our products are safe and of high quality, and we have ISO certifications and follow all industry rules. All of our filtration equipment will work the same way every time and last a long time because of our strict manufacturing and inspection processes.

HQ Address

No.111 Fengxiang Road, Tonglu Economic Development Zone, Hangzhou, Zhejiang Province

Email Address

info@longonefiltra.com