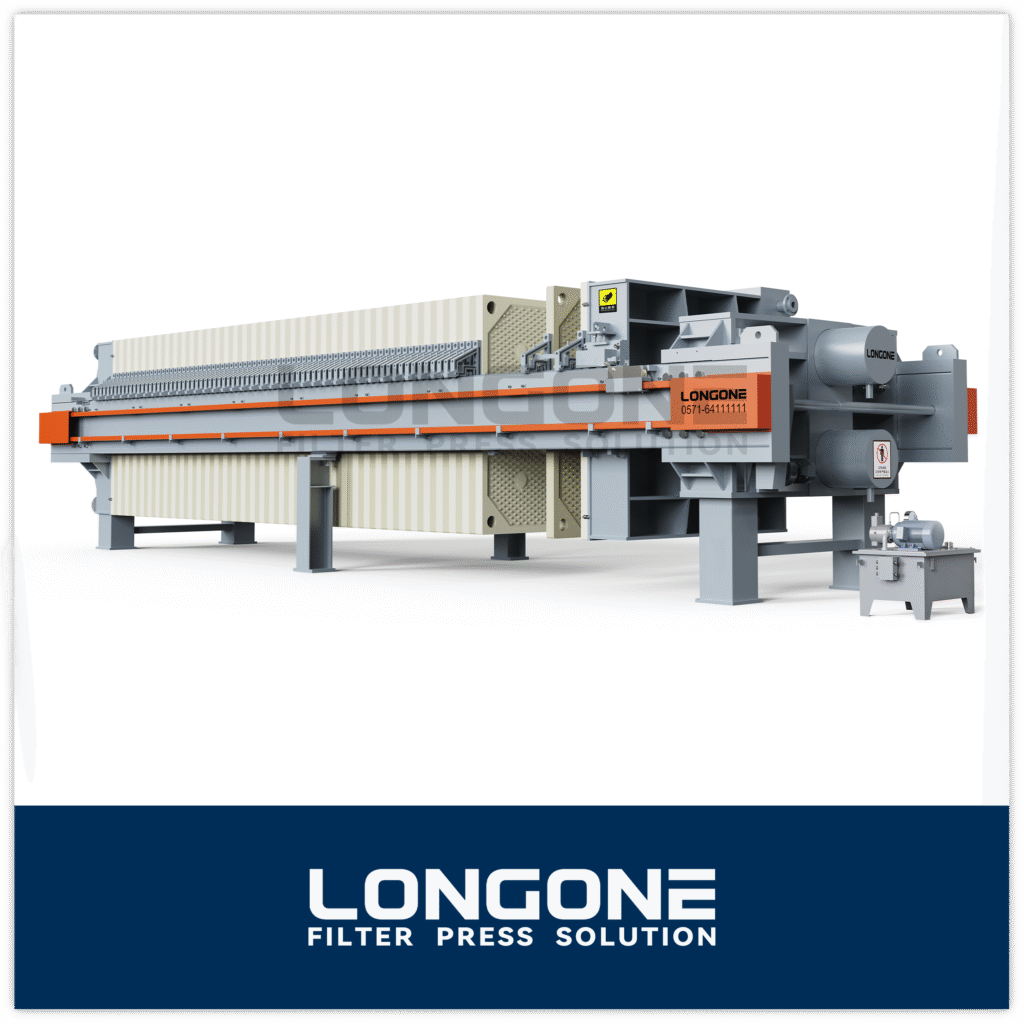

A filter press is a critical piece of equipment in solid-liquid separation. Whether used in wastewater treatment, mining, or chemical production, its performance depends not only on its design but also on how well it is installed and maintained. Even the most advanced membrane filter press can underperform—or even fail—if improper installation causes misalignment, pressure imbalance, or oil system failure.

This guide provides a complete, easy-to-follow overview of filter press installation, startup, and maintenance to ensure long-term stability and efficiency.

1. Preparation Before Filter Press Installation

Before unpacking the filter press, ensure the installation site meets all the requirements for load-bearing, drainage, and accessibility.

Even though every filter press is calibrated and tested at the factory, transportation and handling can cause minor frame deformation or loosened components. Therefore, reassembly and readjustment on-site are essential.

Key Steps:

- Check the foundation level. The entire frame must remain perfectly horizontal. Use metal shims if needed.

- Verify frame alignment. Use the diagonal-line method to correct torsional distortion; the centerline error should not exceed 2 mm, and coaxiality tolerance between the frame hole and guide beam should be within 0.02 mm.

- Inspect anchor bolts. If the foundation bolts are corroded, rebuild the base and apply anti-corrosion sealing materials.

- Check main beam wear. If wear exceeds 2 mm, reinforce or replace it. After replacement, verify the distance between the two beam centerlines and the screw rod—error should be under 1.5 mm.

A stable foundation is the backbone of every filter press installation. Any deviation here may lead to vibration, leakage, or early mechanical failure.

2. Safe Lifting and Positioning of the Filter Press

During lifting, attach the hoisting ropes to the designated lifting holes and confirm the equipment’s balance before hoisting. Choose proper lifting straps that can safely bear the full load of the unit.

Safety Guidelines:

- Never attach ropes to the filter plates or frames directly, as it can damage their sealing surface.

- Maintain horizontal accuracy within +3 mm once positioned.

- Do not fix both rear feet of the hydraulic cylinder. Restricting thermal movement may lead to beam deformation during operation.

If installed outdoors, ensure the system is protected from rain and sunlight to avoid corrosion and hydraulic failure.

Proper hoisting and leveling not only ensure operator safety but also prevent structural stress during operation.

3. Hydraulic and Electrical System Setup

Before connecting the power, perform a full inspection of the hydraulic station and electrical box.

The filter press hydraulic system controls plate compression and release; improper setup may damage seals, pumps, or valves.

Installation Guide:

- Fill the hydraulic tank completely with oil. Never run the system dry. Dry starts can immediately damage the hydraulic pump.

- Drain any water from the oil tank that may have entered during transport.

- Connect the wiring terminal inside the cylinder seat junction box with the corresponding terminal in the control cabinet.

- After energizing, check that the motor rotates clockwise. Reverse rotation can cause system malfunction.

- For membrane filter press installation, verify that the air or water supply line for the squeezing system is connected and leak-free.

A reliable hydraulic and electrical connection is fundamental to ensure safe, automatic filter press operation.

4. Filter Press Operation Sequence

Operating a filter press requires following a precise sequence to maintain system balance and prevent leakage or damage.

Standard Filter Press Operation Manual:

- Start the machine.

- Press filter plates until full contact and maintain pressure.

- Begin feeding slurry into the press.

- Keep pressure steady; monitor gauge readings.

- Start washing and squeezing if required.

- Reverse the cycle for filter cake discharge.

- Open the press, pull plates sequentially, and remove cakes.

- Clean the filter cloths before the next cycle.

- Stop the machine and release pressure.

Important Notes:

Never release the filter plate while feeding continues—this can cause slurry ejection and serious injury.

- Keep the filter cloth surface clean and unfolded.

- During cake discharge, ensure no residual sludge remains in the chamber.

- Always cut off the main power and release system pressure before performing maintenance.

Correct sequence equals safe operation. Every deviation increases wear and risk.

5. Troubleshooting and Common Operating Issues

Even with perfect installation, problems can occur during startup or operation. Understanding their causes helps you act fast.

Common Problems and Solutions:

| Issue | Likely Cause | Recommended Action |

|---|---|---|

| Hydraulic cylinder not moving | Solenoid valve stuck / Insufficient hydraulic oil | Clean or replace solenoid valve; refill oil |

| Pressure unstable or motor repeatedly starts | Check valve stuck / Feed pressure too high | Clean or replace check valve; reduce feed pressure |

| Filter plate breakage | Feed pressure >8Kg / Cloth damage / Inlet blockage | Replace damaged cloth; clear inlet; regulate feed |

| Slurry leakage | Filter plate misalignment / Cloth folded | Re-align plates; flatten cloth |

| Unbalanced compression | Uneven hydraulic pressure | Inspect seals and oil pump |

Tip: If adjustments don’t solve the problem, contact the manufacturer for technical support. Longone provides remote troubleshooting and on-site service.

6. Daily Filter Press Maintenance

Preventive maintenance reduces breakdowns and extends equipment life. The following checklist applies to all types of presses, including chamber filter press and membrane filter press.

Daily Tasks:

- Keep the plate pulling rails clean; apply hydraulic oil as lubrication.

- Lubricate chains and sprockets with anti-rust oil.

- Inspect the sealing surface daily and clean sludge residue.

- At the end of each shift, wipe off dust and debris around the hydraulic area.

Periodic Maintenance:

- Change hydraulic oil every 6 months. If emulsified or contaminated with water, replace immediately.

- Check the feed pipeline and pressure gauge for leaks.

- Verify that the limit switches are functioning correctly.

- Never reduce the number of plates arbitrarily—it may shorten the hydraulic stroke and cause structural failure.

Proper maintenance ensures long-term filter press stability, consistent filtration performance, and reduced downtime.

7. Filter Press Safety Precautions

Safety during filter press operation cannot be overstated. Operators should receive proper training and always follow the company’s filter press safety manual.

Safety Checklist:

- Never stand in front of the hydraulic cylinder when the press is operating.

- Ensure the plate-pulling car is in its starting position before pressing or releasing.

- Do not start the automatic plate puller until the cylinder has fully retracted.

- When feeding, open the feed valve halfway at first—only fully open it after all water outlets discharge.

- If your slurry contains branches, fibers, or roots, use a protective mesh to prevent clogging and filter plate damage.

- Never alter pressure settings without consulting the manufacturer.

- Always use original spare parts and filter cloths for optimal sealing and lifespan.

Following these safety measures minimizes the risk of injury and protects your investment.

8. The Role of Professional Installation Support

Even with a complete filter press installation guide, professional technical assistance ensures higher reliability.

Longone provides comprehensive on-site installation supervision, system calibration, and after-sales maintenance.

If your site has unique requirements—such as outdoor installation, high-pressure membrane systems, or custom automation—our engineering team can adjust your setup to maintain optimal performance and extend the equipment’s lifespan.

9. Summary

A well-installed filter press delivers stable filtration, lower cake moisture, and long service life.

From foundation leveling to hydraulic setup, every detail matters.

Regular filter press maintenance and compliance with operation manuals are essential to safety and efficiency.

For professional filter press installation, technical consultation, or maintenance support, contact us.