Different types of filter cloths are made from different materials, and choosing an unsuitable filter cloth can lead to excessive moisture content in the filter cake and frequent shutdowns, thus increasing operating costs. Selecting the appropriate material can solve these problems.

The best filter press cloth material depends on slurry properties, chemical conditions, and filtration pressure. Common materials such as polypropylene (PP), polyester (PET), and nylon are widely used because they balance filtration efficiency, durability, and cost. Selecting the correct material improves cake dryness, extends cloth life, and ensures stable long-term operation.

Understanding filter cloth fundamentals helps you make better material decisions.

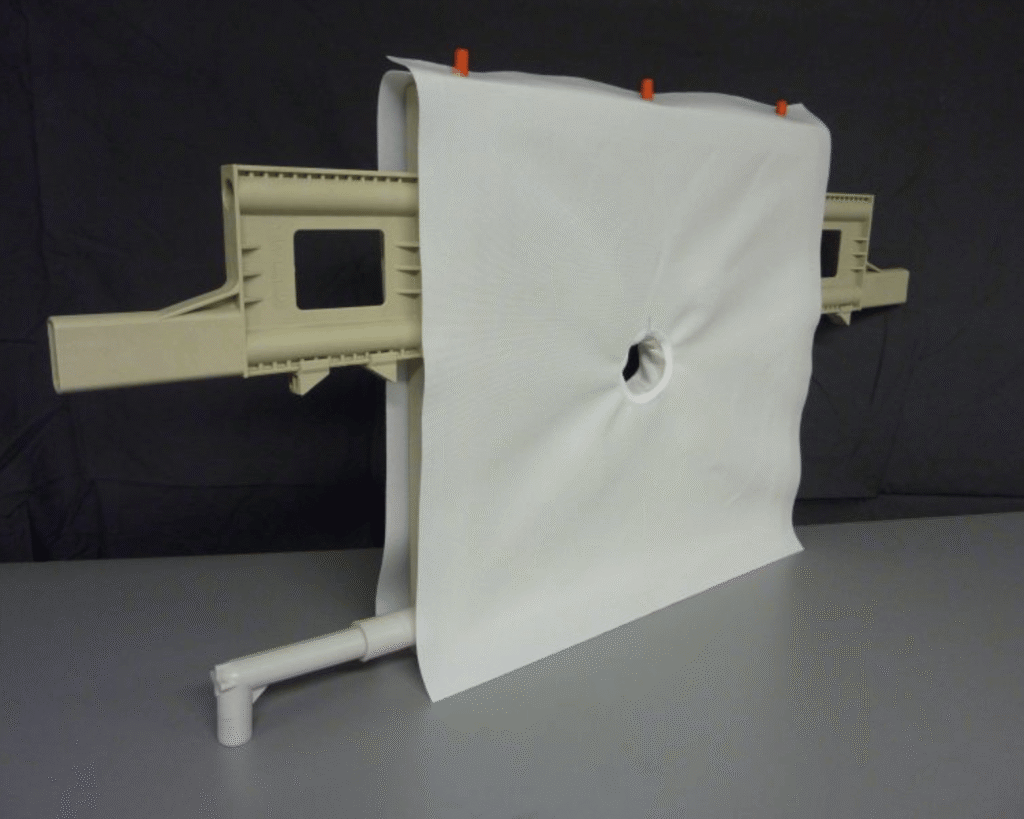

What Is Filter Cloth?

Filter cloth is the main part of the filter plates that separates solids from liquids during the press cycle.

Filter cloths for filter press systems let liquids through but keep solids in. The size of their pores, the structure of their surface, and the material they are made of all affect how quickly they filter and how good the cake is.

In industrial filtration, the performance of the filter cloth decides if the press works well or gets clogged and has trouble releasing the cake. A good cloth stays permeable under pressure, doesn’t break down when it comes into contact with chemicals, and can be used for continuous production without having to be replaced often.

Common Filter Press Cloth Materials

Different types of filter press cloth are made to meet different chemical, mechanical, and operational needs. Choosing the right material is very important for how well the filter works and how long the cloth lasts.

Polypropylene (PP), polyester (PET), and nylon are the most common materials used to make filter cloths in factories. Depending on the conditions of the process, each material has its own benefits.

- Polypropylene (PP) is the most widely used filter press cloth material. It offers excellent resistance to acids and alkalis, low moisture absorption, and stable performance under high filtration pressure. PP filter cloths are ideal for wastewater treatment, mining, and chemical processes where chemical stability and cost efficiency are required. Their smooth surface also improves cake release and reduces cleaning frequency.

- Polyester (PET) filter cloths perform well in higher-temperature environments and offer better resistance to oxidizing chemicals. PET materials maintain dimensional stability and strength during long filtration cycles. They are commonly used in chemical processing, metallurgy, and industries where operating temperatures exceed standard PP limits.

- Nylon filter cloths are known for high tensile strength, abrasion resistance, and elasticity. These properties make nylon suitable for applications involving coarse or abrasive particles. However, nylon has lower resistance to strong acids and alkalis, so material compatibility must be carefully evaluated before selection.

- Specialized materials, such as PTFE-coated or blended fabrics, are used in extreme conditions involving high temperatures, aggressive chemicals, or strict filtrate purity requirements. These materials are typically customized for specific industrial processes.

Choosing the right filter cloth material ensures consistent filtration performance and longer service life.

Filter Press Cloth Material Specifications

Clear technical parameters help buyers quickly compare different filter cloth materials and select the most suitable option.

| Filter Press Cloth Material | Weight (±5%) | Air Permeability (L/㎡·s ±20%) | Thickness (mm ±10%) |

|---|---|---|---|

| Polypropylene (PP) | 400–800 g/m² | 100–300 | 1.2–2.5 |

| Polyester (PET) | 450–850 g/m² | 80–250 | 1.3–2.8 |

| Nylon | 420–780 g/m² | 90–260 | 1.2–2.6 |

These specifications allow faster evaluation of filtration capacity, durability, and compatibility with specific filter press conditions.

Why Is Filter Press Cloth Essential?

Many problems with filtration come from choosing the wrong filter cloth instead of the wrong equipment design.

Using the right filter press cloth material makes the cake drier, speeds up the filtration process, and makes the machine more stable.

Using the wrong cloth can cause blinding, tearing, or bad cake discharge, which can lead to downtime and higher maintenance costs. When you choose the right filter cloths, they stay permeable under pressure, use less energy, and keep the factory running all the time. This has a direct impact on the efficiency of production and the total cost of ownership for B2B users.

The quality of the filter cloth has a direct effect on how well the filter works.

Fabric Weave and Structure

Material alone does not determine performance; fabric structure plays an equally important role.

Monofilament, multifilament, woven, and non-woven designs influence permeability and cake release.

Monofilament cloths provide smooth surfaces and high permeability, making them easy to clean and ideal for applications requiring fast filtration.

Multifilament cloths offer finer filtration but may retain more particles within the fabric.

Woven fabrics provide strength and dimensional stability, while non-woven fabrics are used for polishing filtration or low-pressure processes.

Matching fabric structure with material improves filtration efficiency and service life.

What Industries Commonly Use Filter Cloths?

Many businesses and governments use filter cloths for filter press systems.

Filter cloth performance is very important for the mining, chemical processing, wastewater treatment, and aggregate industries.

Filter cloths are used in mining and mineral processing to handle abrasive slurries under high pressure. Chemical plants need materials that won’t corrode when they come into contact with chemicals.

Municipal and industrial wastewater treatment plants work to lower disposal costs by drying out sludge. Every industry needs filter cloth material solutions that are made just for them.

How to Choose the Right Filter Cloth for Your Needs?

Choosing the right filter press cloth material starts with understanding your process requirements.

Material compatibility, fabric structure, and operating conditions should guide selection.

Evaluate slurry particle size, chemical composition, filtration pressure, and temperature. Match these conditions with suitable materials such as PP, PET, or nylon. Consider cake discharge behavior and maintenance cycles. For complex or demanding applications, customized filter cloth solutions often provide better long-term value than standard products.

The right choice reduces cost and improves filtration performance.

Conclusion

Selecting the right filter press cloth material is essential for achieving efficient solid-liquid separation, stable operation, and lower long-term costs. By understanding material properties, fabric structure, and technical specifications, industrial users can significantly improve filtration performance and extend equipment service life.

Contact us today to discuss your filtration requirements and receive a professional recommendation tailored to your process.