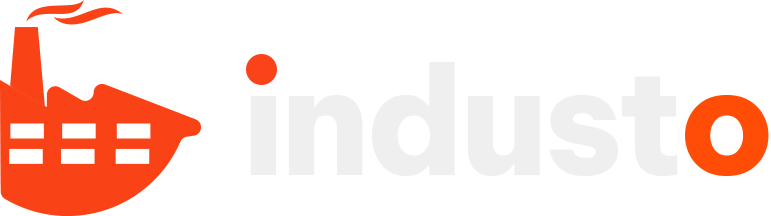

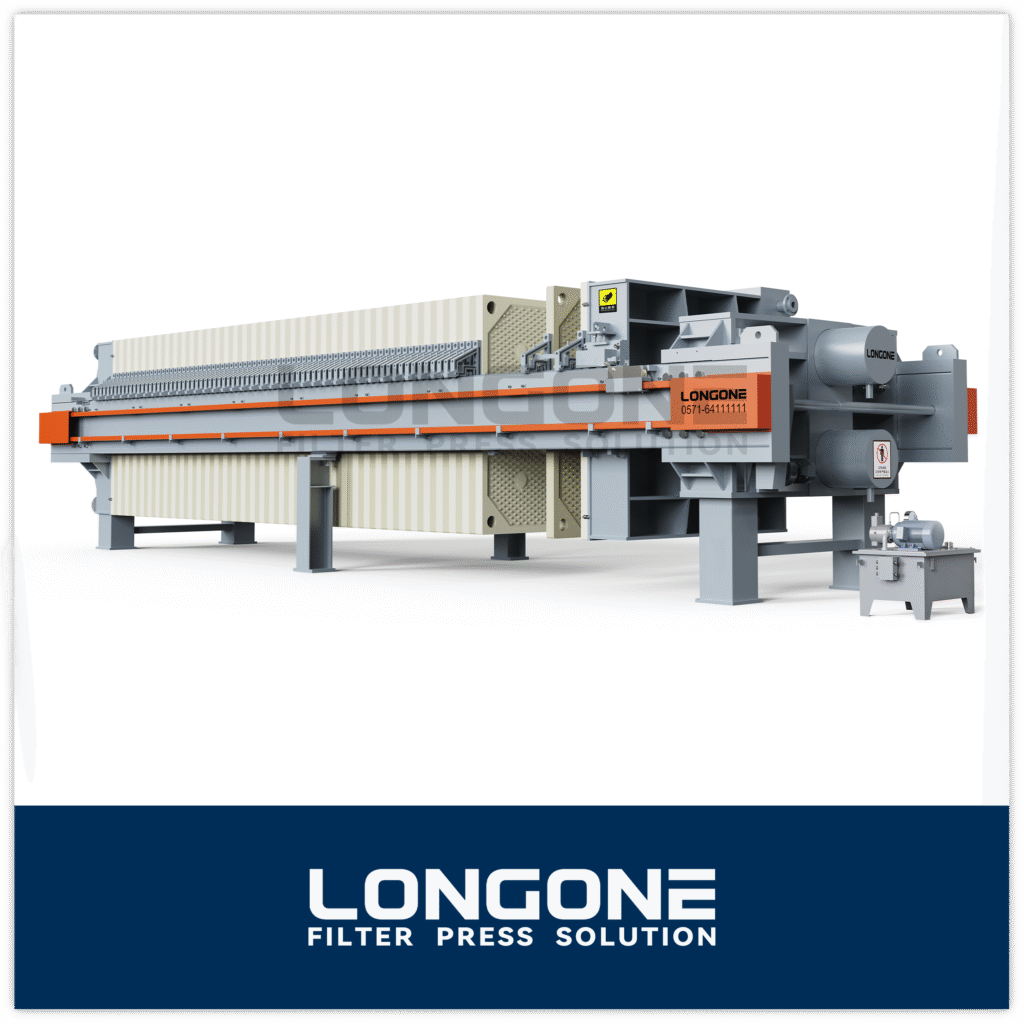

LONGONE is a top maker of chamber filter presses in China. They focus on making high-efficiency chamber filter presses for treating sludge, chemicals, and industrial wastewater. Our presses have PP filter plates that last a long time, high filtration pressure, and automatic cloth cleaning systems. These features make sure that they work well and last a long time. Our chamber filter press makes high-quality filter cakes by easily separating solids from liquids. It has a simple design and is easy to use. LONGONE’s solutions are widely used in the food, mining, chemical processing, and municipal sewage industries. They offer great value for money and dependable results. Our chamber filter press is the best choice for clients all over the world because it works well, is easy to maintain, and is reliable for both high-frequency operations and tough dewatering tasks.

A chamber filter press is a solid-liquid separation device that uses parallel filter plates with cloths to form chambers. Under high pressure, it efficiently filters and dewaters sludge, slurry, and other industrial materials, producing uniform filter cakes.

Widely used in municipal sewage, chemical processing, mining, and food industries, the chamber filter press features simple operation, durable filter plates, high filtration pressure, automatic cloth cleaning, and long service life.

filter press manufacturer

Product Name:chamber filter press

Category: Filter Press

Brand: LONGONE

Minimum Order Quantity: 1 unit

Origin: Zhejiang Province, China

OEM Customization: Supported

In Stock Status: In Stock

Price: Negotiable

Payment Method: OA, TT, LC

Delivery Time: 30-45 days

China Filter Press

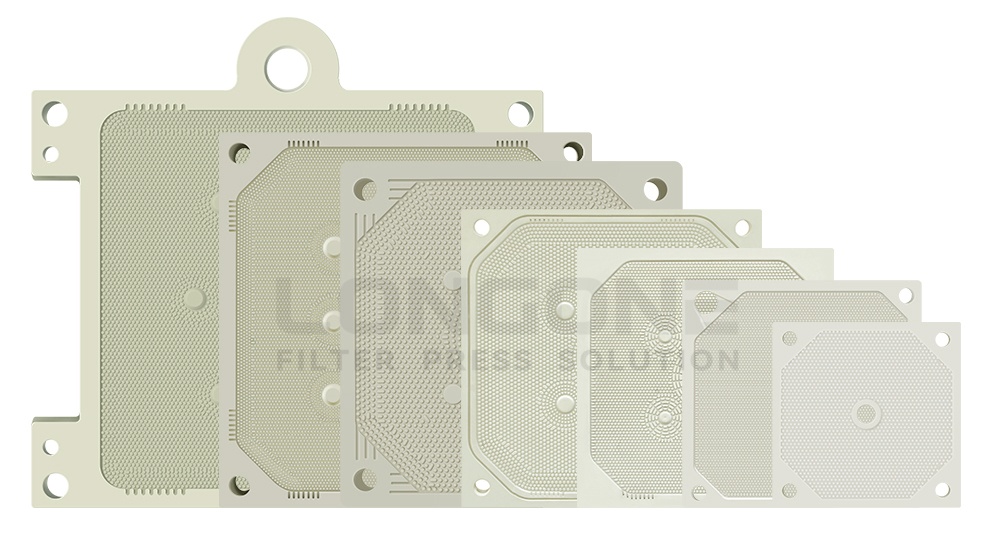

| Parameter Item | Value |

|---|---|

| Plate Size | 630×630 mm to 2000×2500 mm |

| Filtration area | 1 m² – 1200 m² |

| Chamber Depth | 10 mm – 60 mm |

| Filtration pressure | up to 1.5 MPa |

| Cake thickness | 30 – 40 mm |

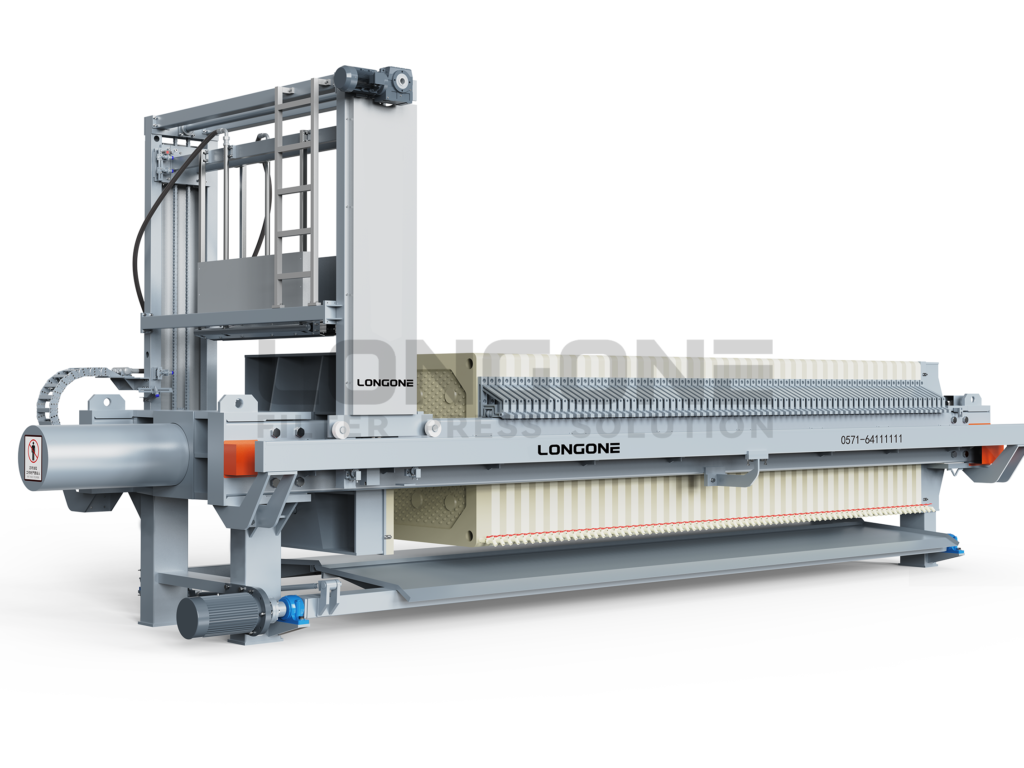

Advantages of Filter Press

The chamber filter press has many advantages for separating solids and liquids quickly and easily:

High Filtration Pressure: Can handle up to 4.0 MPa for faster, better dewatering.

Long-lasting Filter Plates: PP plates don’t rust, corrode, or react with acids or bases, so they last a long time.

Automatic Cloth Cleaning: Cuts down on downtime and maintenance costs.

Simple to Use: The hydraulic system and mechanical locking make it easy to use and keep up.

Consistent Filter Cake Quality: Makes solids that are all the same and have a lot of dry matter.

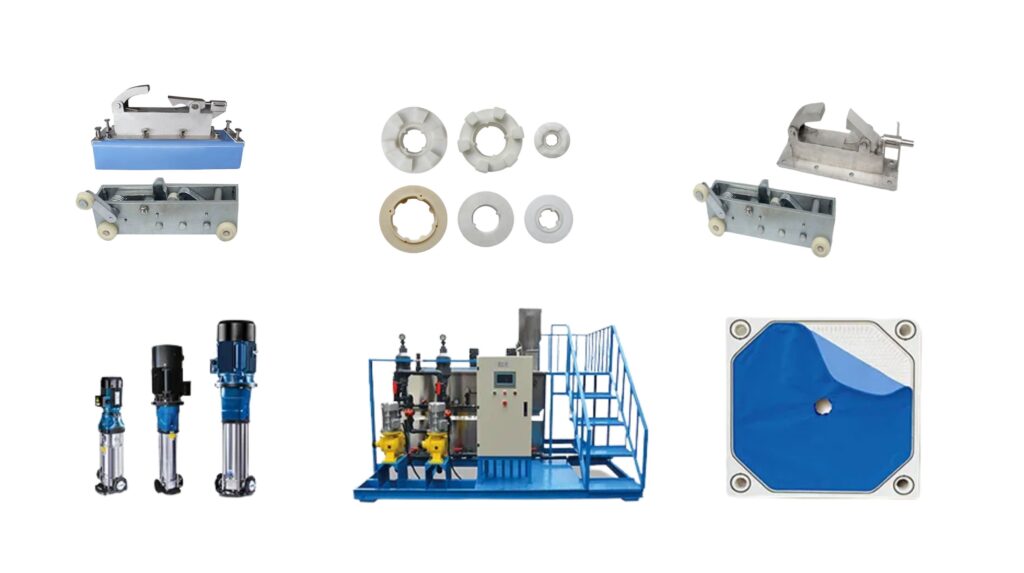

Our reinforced PP filter plates are very strong, don’t rust, and work consistently. They are made for chamber filter presses and make sure that the filtering is efficient, the service life is long, and the sealing is reliable.

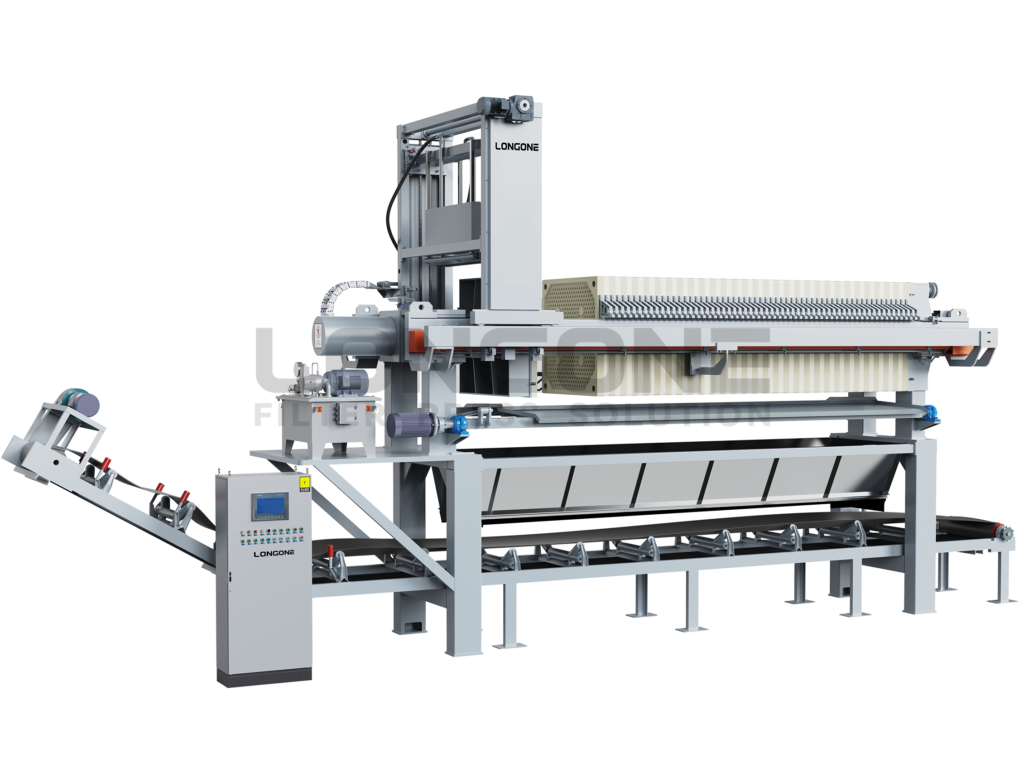

Our conveyors are strong and easy to care for. They move filter cakes and other materials quickly and easily, making work easier and cutting down on the need for manual handling in sludge treatment and industrial filtration processes.

We have everything you need, from dosing systems to filter cloths, cloth clamps, feeding pipes, and hoppers, to make sure your filter press system works as well as possible and fits in perfectly.

Our Promise to You

High Technology

Advanced filtration technology ensures reliable performance and improved dewatering efficiency.

Quality Assurance

Strict quality control guarantees durable, stable, and long-lasting filtration equipment.

Customized Service

Tailored filtration solutions designed to meet your unique process and application needs.

Fast Logistics

Efficient global shipping ensures timely delivery for all filtration equipment orders.

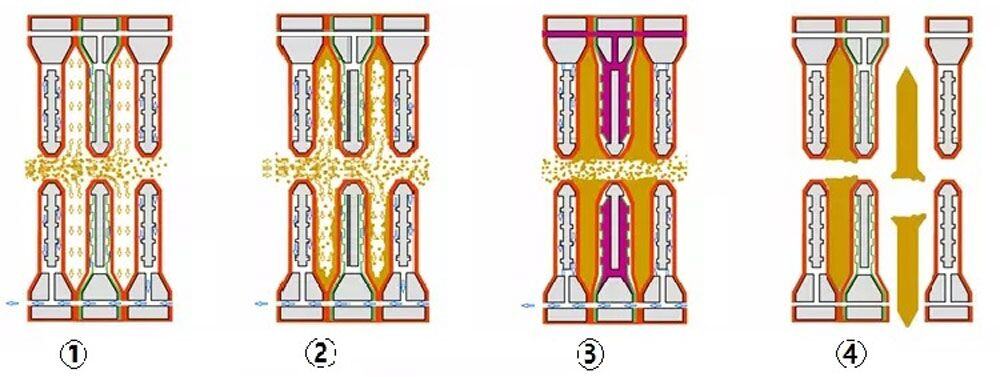

How a Chamber Filter Press Works

The chamber filter press uses a high-pressure filtration process to separate solids and liquids quickly and easily.

1. Feeding: The central inlet lets the slurry in, filling each chamber evenly.

2.Filtration: Liquid goes through the filter cloth and leaves through drainage channels. Solids build up to make filter cakes.

3.Pressing and drying: High pressure makes sure that the cake has a low moisture content and is evenly formed.

4.Cake Discharge: The plates open up after filtration is done, making it easy for cakes to fall.

This simple and reliable process guarantees consistent performance, high efficiency, and great dewatering results in a wide range of industrial settings.

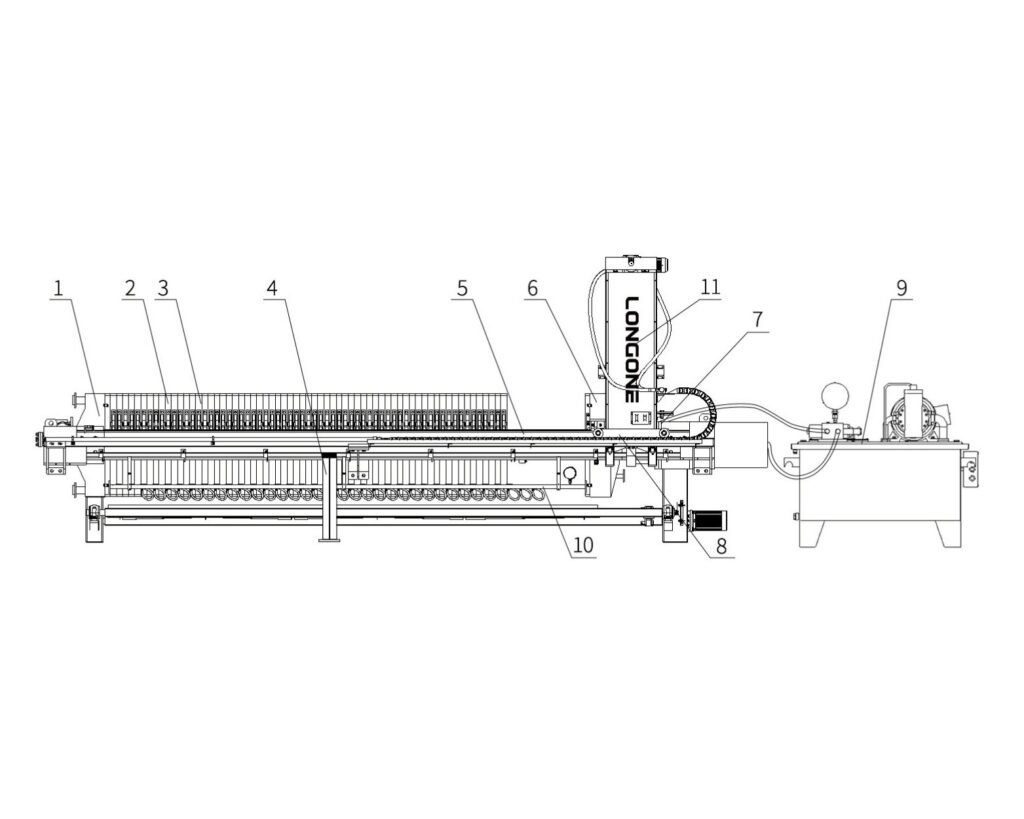

Main Components

The structure of a chamber filter press is strong and built to last, so it can filter things out quickly, efficiently, and for a long time. The main parts of it are:

- Frame System: A welded steel structure that provides strength, stability, and support for all components.

- Filtration System: Includes chamber filter plates, filter cloths, and optional membranes for efficient solid-liquid separation.

- Hydraulic System: Automatically clamps and releases plates using a hydraulic cylinder for safe and reliable operation.

- Plate-Shifting System: Ensures smooth, automatic opening and closing of filter plates.

- Electrical Control System: Smart PLC control for automated feeding, pressing, cloth washing, and cake discharge.

Applications of Chamber Filter Press

Many industries that need to separate solids from liquids quickly and reliably use the chamber filter press. Because it can filter at high pressure, it is good for:

Municipal sewage treatment: drying out sludge to lower the amount of waste and the cost of getting rid of it.

Industrial Wastewater: Cleaning up wastewater from textiles, metallurgy, dyeing, and making things.

Chemical Processing: Removing catalysts, pigments, and other chemicals from the mix.

Mining and Minerals: Getting rid of water from tailings, concentrates, and mineral slurries.

Food and Drink: Making liquids clear and getting rid of organic waste.

Construction Materials: Used in making ready-mix concrete, lime softening, and cement.

Shipping and Delivery

We offer secure, reinforced packaging and dependable global transportation to ensure every chamber filter press and accessory arrives safely, on time, and in perfect working condition.

Related products

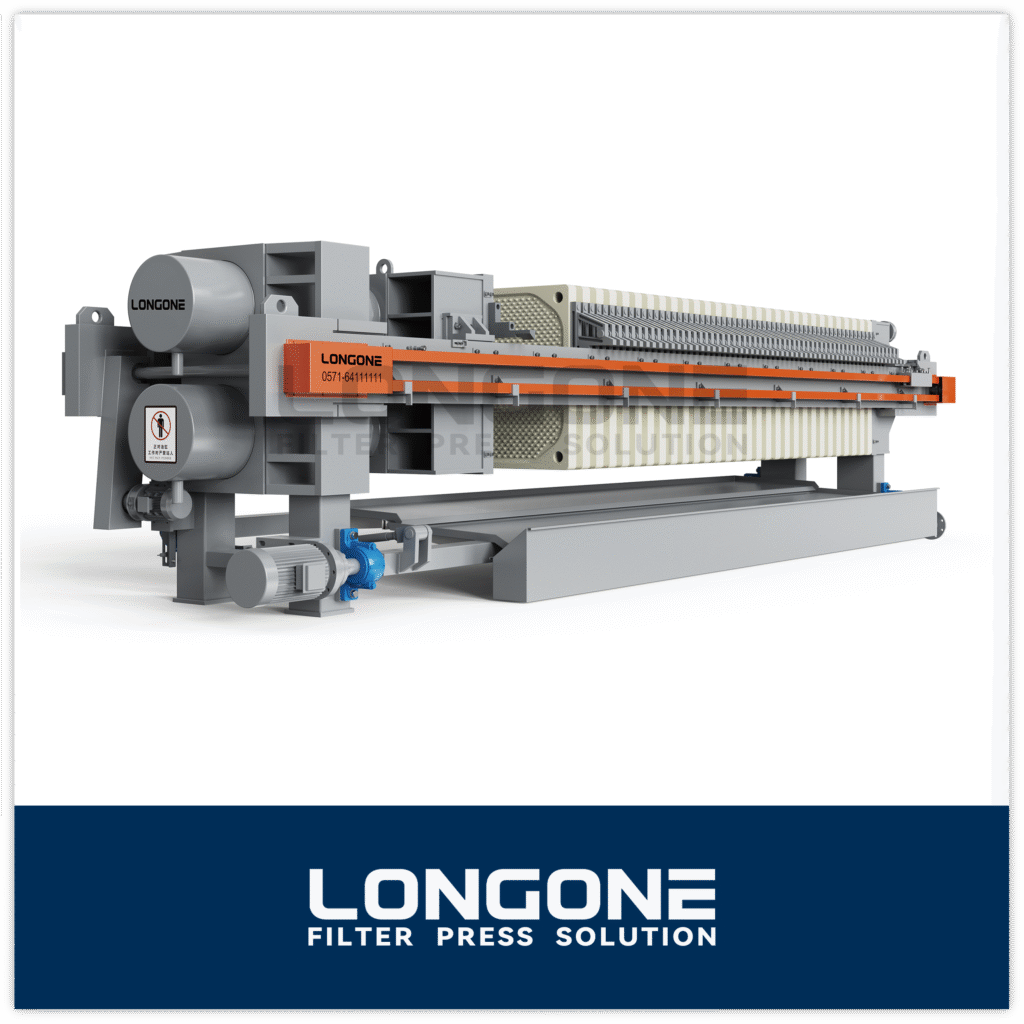

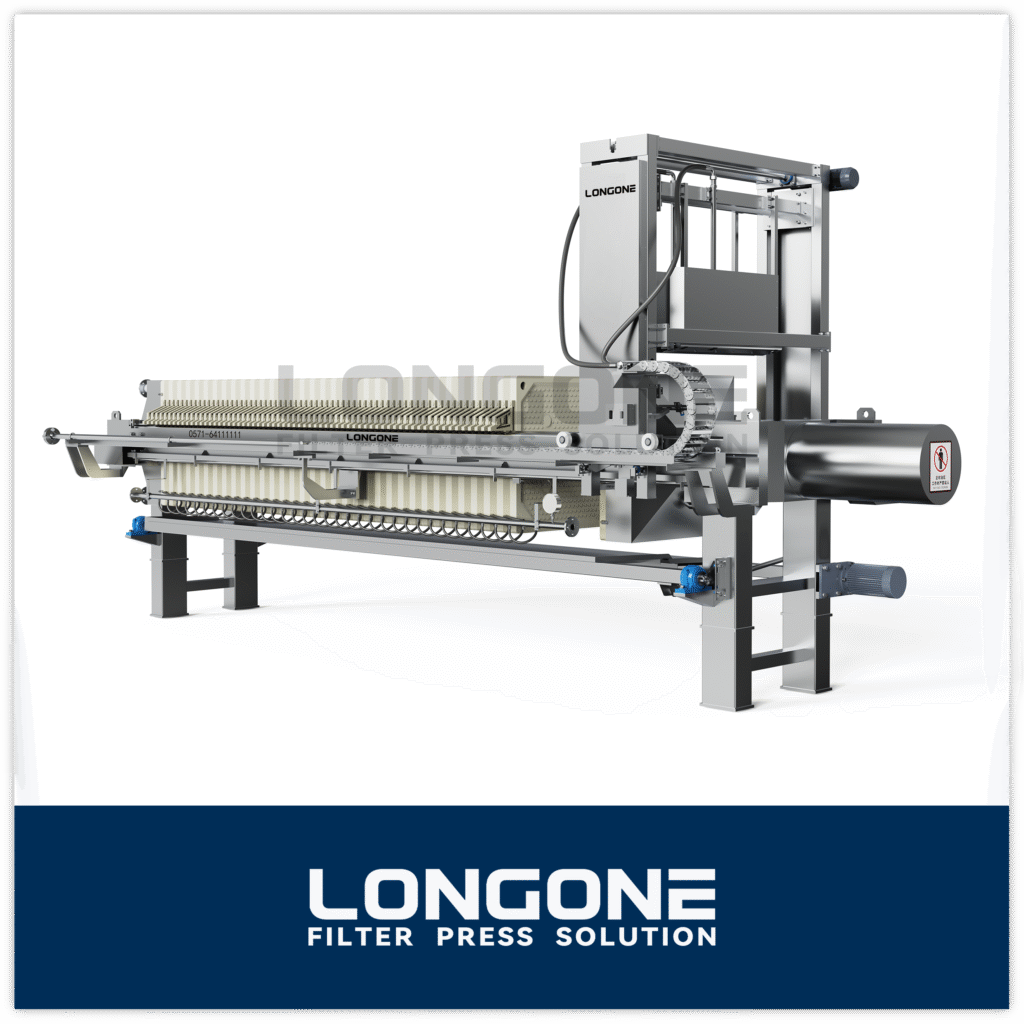

To meet different application needs, we also offer a full range of filtration solutions, such as the Frame And Plate Filter Press , Membrane Filter Press,Sludge Filter Press,Stainless Steel Filter Press, and Lab Filter Press.

HQ Address

No.111 Fengxiang Road, Tonglu Economic Development Zone, Hangzhou, Zhejiang Province

Email Address

info@longonefiltra.com