As a leading automatic filter press manufacturer, we offer fully automated filtration systems that are made for solid-liquid separation that is continuous, high-volume, and efficient. Our solutions use advanced engineering, smart PLC control, and more than 15 years of experience in filtration to make sure that they work well, need little manual intervention, and give great results. Each system can be changed to fit the needs of a specific process, which helps businesses lower their costs and get more done.

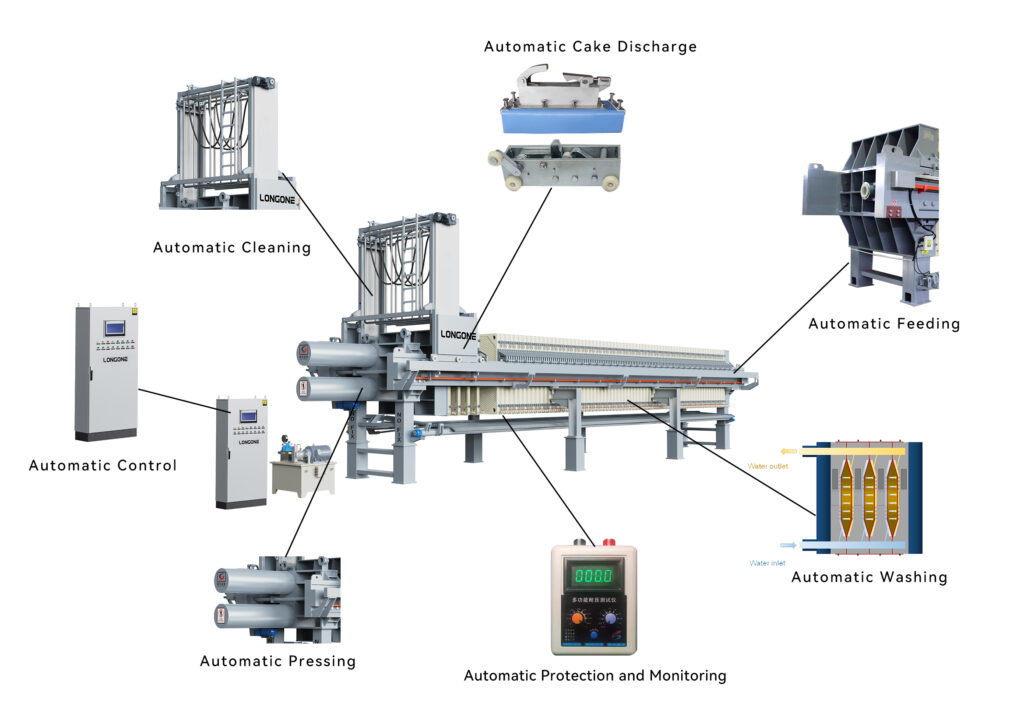

- Advanced Automation – Automatic cake discharge, cloth washing, pressure control, and remote monitoring.

- High Efficiency – Short cycle time and high dryness level with solid content up to 75%.

- Robust Construction – Heavy-duty structure designed for demanding industrial environments.

- Custom-Built Solutions– We can make the filtration area, number of plates, and control system just right for your needs.

An automatic filter press is a completely automated system for separating solids and liquids. It uses pressure filtration to make very dry filter cakes with little help from an operator. It combines PLC control, automatic plate shifting, cake discharge, and cloth washing to make sure that filtration works all the time, is reliable, and can handle a lot of volume.

Automatic filter presses are used a lot in mining, metallurgy, food production, wastewater treatment, and the drying of sludge in cities and industries. Contact us today for professional help and tailored solutions if you need technical advice or want to choose the right model for your needs.

Filter Press manufacturer

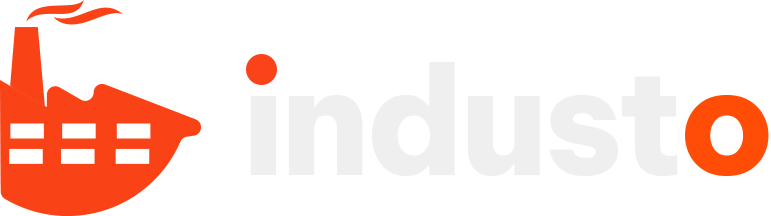

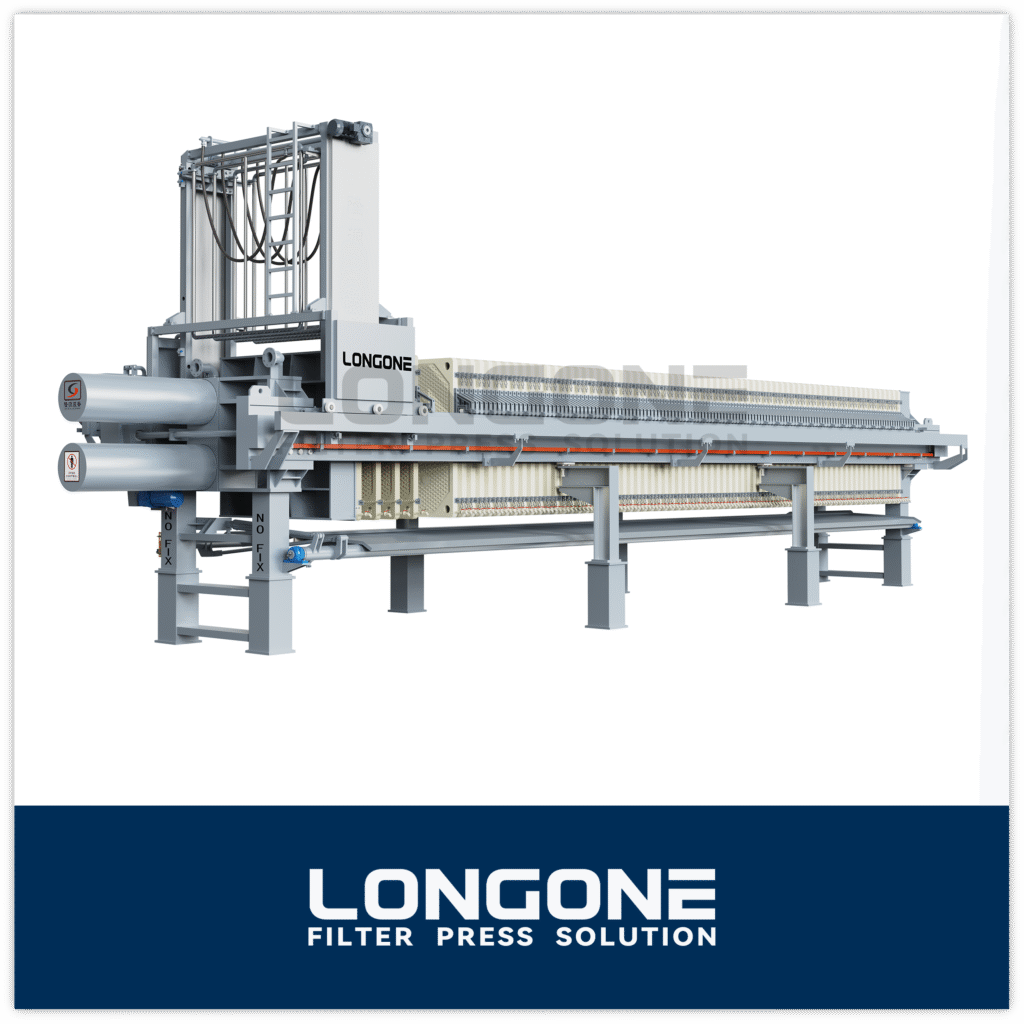

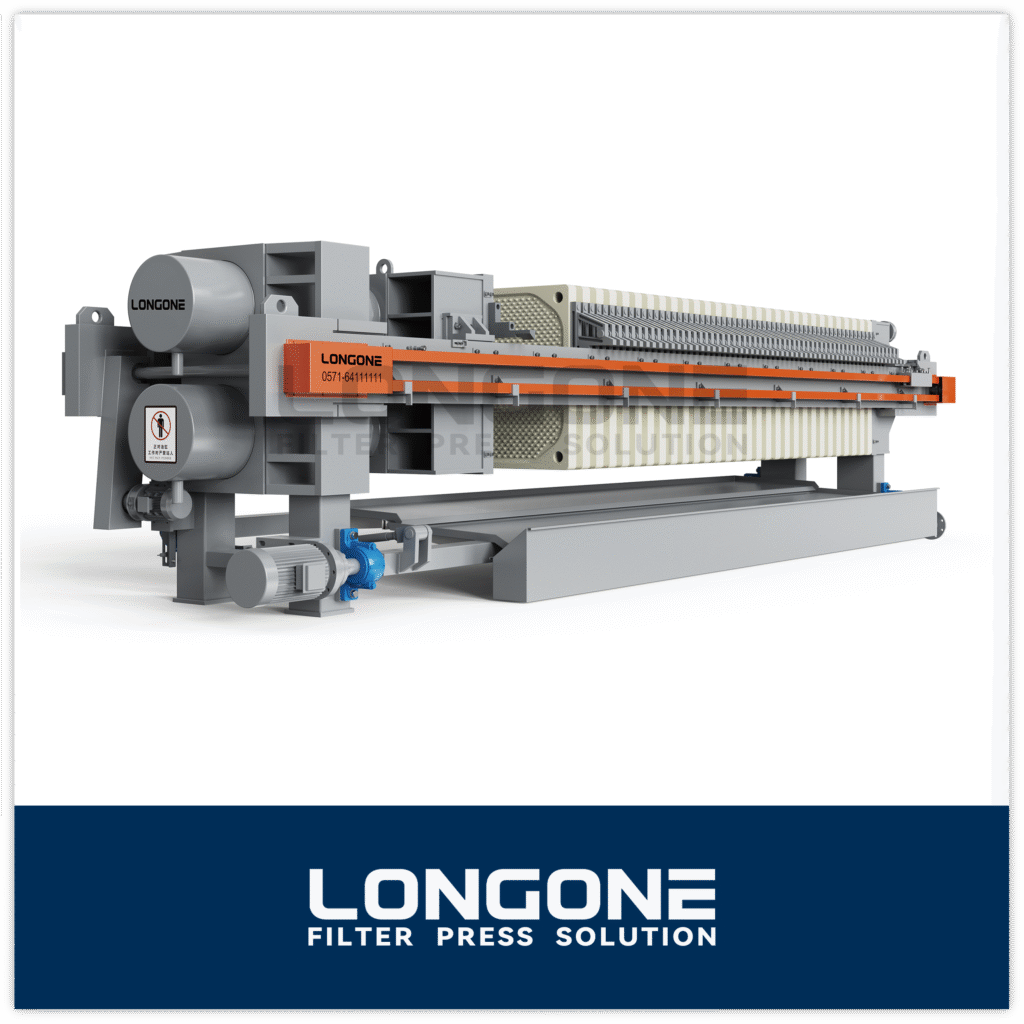

Product Name: Automatic Filter Press

Brand Name: LONGONE

Type: Semi-automatic, Fully Automatic, Fully Automatic

Customization: Supported

Filter Press Price: Negotiable

Minimum Order Quantity: 1 unit

Applications: Suitable for industries with medium to high throughput and requiring continuous automated dewatering.

Technical Specifications

| Specs | Details |

|---|---|

| Filtration Area | 5–100 m² |

| Capacity | 0.1–125 tons of dry solids/hour |

| Plate Quantity | 20–94 plates |

| Final Cake Moisture | Up to 75% solid content |

| Cycle Time | 8–30 minutes |

System Composition

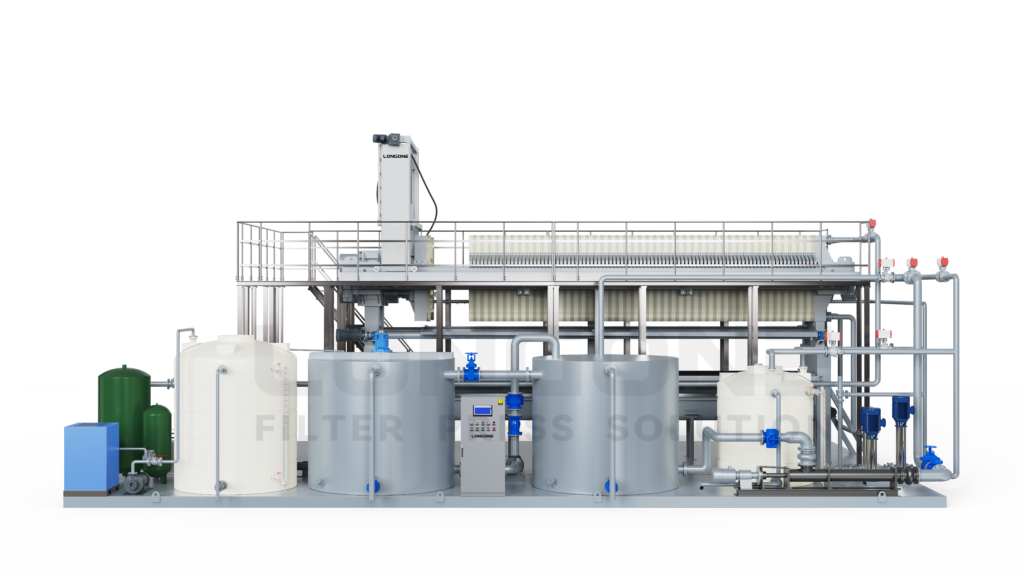

An automatic filter press system is designed with built-in mechanical and automation parts to make sure that filtration is stable, continuous, and very efficient. The main parts of the system are:

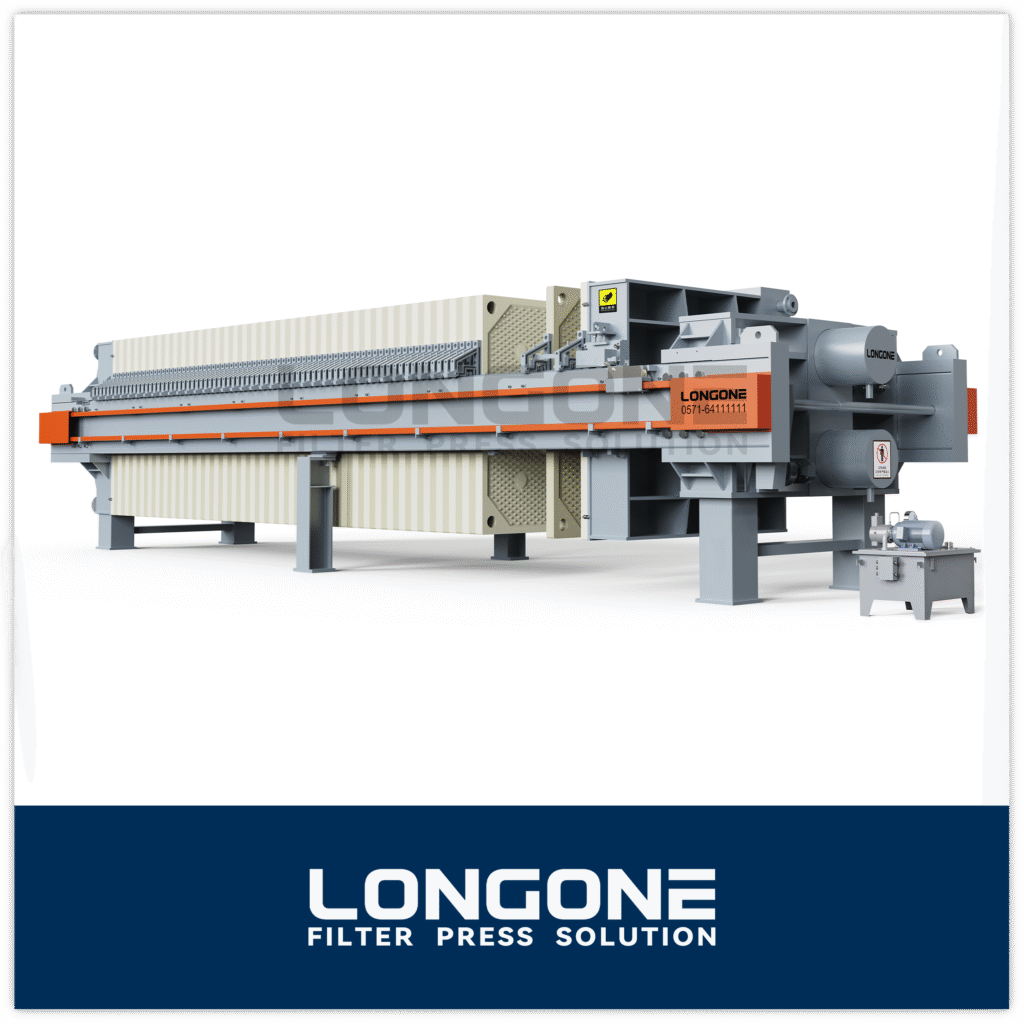

Mechanical Structure: Heavy-duty frame, side-beam design, filter plates, hydraulic closing system.

Automation Modules: PLC control panel, SCADA/remote monitoring, sensors, and pneumatic valves.

Cake Discharge System: an automatic plate shifter, a plate vibrator, drip trays, and a discharge chute.

Cloth Maintenance System: an automatic cloth washing unit and cloth tensioning devices that keep the filtration system working well.

Customization supported

You can fully customize our automatic filter press to fit your process conditions, material properties, and industry needs. We offer flexible engineering options to make sure that your filtration system works as well as possible, costs as little as possible to run, and fits right into your production line. Customization covers mechanical structure, filtration area, automation level, and control systems.

- Filtration Capacity Options – Adjustable filtration area, plate size, and plate quantity for small, medium, or large-scale operations.

- Automation Customization – PLC, SCADA, remote monitoring, variable pressure control, and auto-washing modules.

- Material & Structural Design – Carbon steel, stainless steel, corrosion-resistant coatings, and explosion-proof options.

We incorporate sophisticated mechanical design with intelligent automation in order to provide filtering systems that are engineered for continuous industrial operation and that are characterized by their durability and stability.

From project consultation to installation, training, and remote assistance, our experienced engineers ensure smooth startup, optimized performance, and long-term reliability for every filtration project.

Every automatic filter press undergoes rigorous testing, precision assembly, and full system verification to guarantee consistent performance, safety, and dependable results across all applications.

filter press Solution

Felxible Payment

We accept T/T, L/C at straight, PayPal, and more methods.

Quality Assurance

Quality control at every stage of the manufacturing process.

Effective Logistic

Safe and reliable logistics services covers more than 30 countries.

Customize Service

We can tailor a filter press to your specific needs.

Key Features of Automatic Filter Press

Our automatic filter press is designed to work continuously for industrial filtration with high efficiency, reliability, and full automation. Its advanced design means that you don’t have to do much by hand, the cycles are faster, and the filter cakes are always dry. The system has smart controls and strong mechanical parts that work together, making it perfect for tough jobs that need stable, long-lasting performance.

- Fully Automated Operation – Automatic plate shifting, cake discharge, cloth washing, and pressure control.

- High Filtration Efficiency – Short cycle time and high final solid content up to 75%.

- Robust & Compact Structure – Heavy-duty design ensures stability and long service life.

Applications of Automatic Filter Press

Many industries use automatic filter presses because they are the best way to separate solids from liquids quickly, easily, and with little human intervention. They are perfect for tough production environments because they can deliver dry filter cakes, cut down on labor, and keep performance stable. The system adjusts to different types of slurry, giving reliable results in a wide range of industries.

1.Municipal & Industrial Sludge Dewatering – Wastewater treatment plants, ETP, STP

2.Chemical, Pharmaceutical & Dye Industries – Fine chemicals, pigments, catalysts

3.Mining & Metallurgy – Tailings, mineral concentrates, ore processing

4.Food Processing – Sugar, starch, edible oil, beverage filtration

5.Power & Steel Plants – Ash slurry, flue gas treatment, by-product recovery

Automation Advantages of the Filter Press

Systems for filter presses. The system minimizes human involvement, lowers operating costs, and guarantees consistent filtration quality by combining smart controls with automated mechanical functions. Automatic features speed up the cycle time, make things safer, and keep the output steady in tough industrial settings, making the equipment perfect for big, ongoing production lines.

Some of the main benefits of automation are faster filtration cycles, automatic cake discharge, less need for workers, better cleaning of cloth, and precise control of pump pressure. These changes help factories work better, have less downtime, and stay stable over time.

Business partners are warmly invited to become part of our network of dealers. Enjoy low rates and guaranteed quality by sourcing directly from Chinese filter press companies! LONGONE is dedicated to assisting you in lowering your expenses and in achieving the highest possible return on investment!

Related products

HQ Address

No.111 Fengxiang Road, Tonglu Economic Development Zone, Hangzhou, Zhejiang Province

Email Address

info@longonefiltra.com