A filter press is one of the most efficient tools for solid-liquid separation. To ensure stable operation and extended service life, it’s crucial to understand how filter press components work. In this article, I’ll explain every key part of a filter press and how they work together to deliver optimal performance.

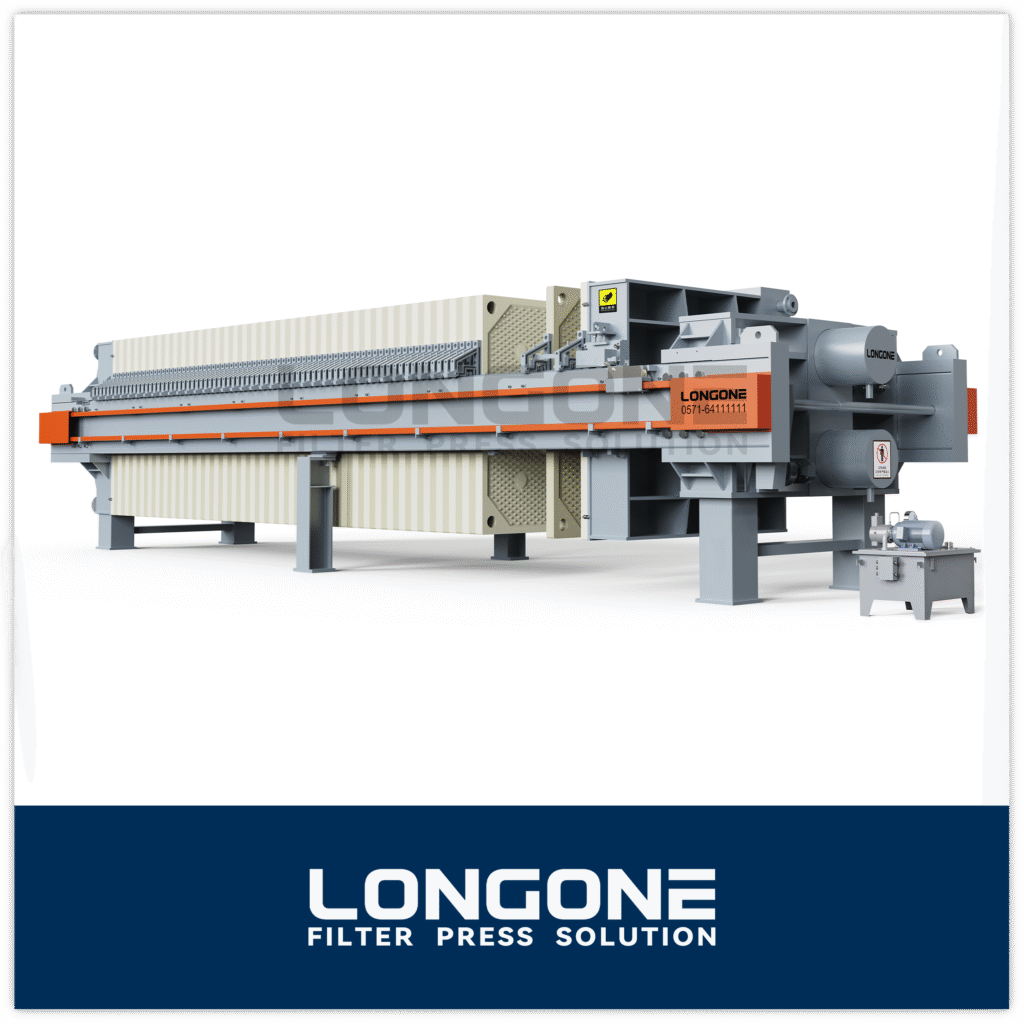

A filter press consists of a strong frame, precision-engineered filter plates, filter cloths, a hydraulic system, and a manifold system (piping and valves). Each part serves a unique function—holding, filtering, or pressing materials—to separate solids from liquids effectively. When properly assembled and maintained, these components provide high-efficiency, low-cost filtration performance across many industrial applications.

Now that you have an overview, let’s explore each part of a filter press in detail and see how proper selection and maintenance ensure long-term filtration efficiency.

Filter Press Components

Frame Components

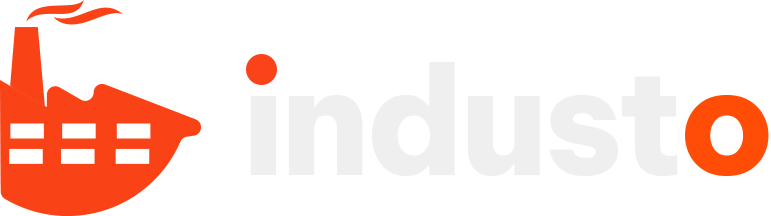

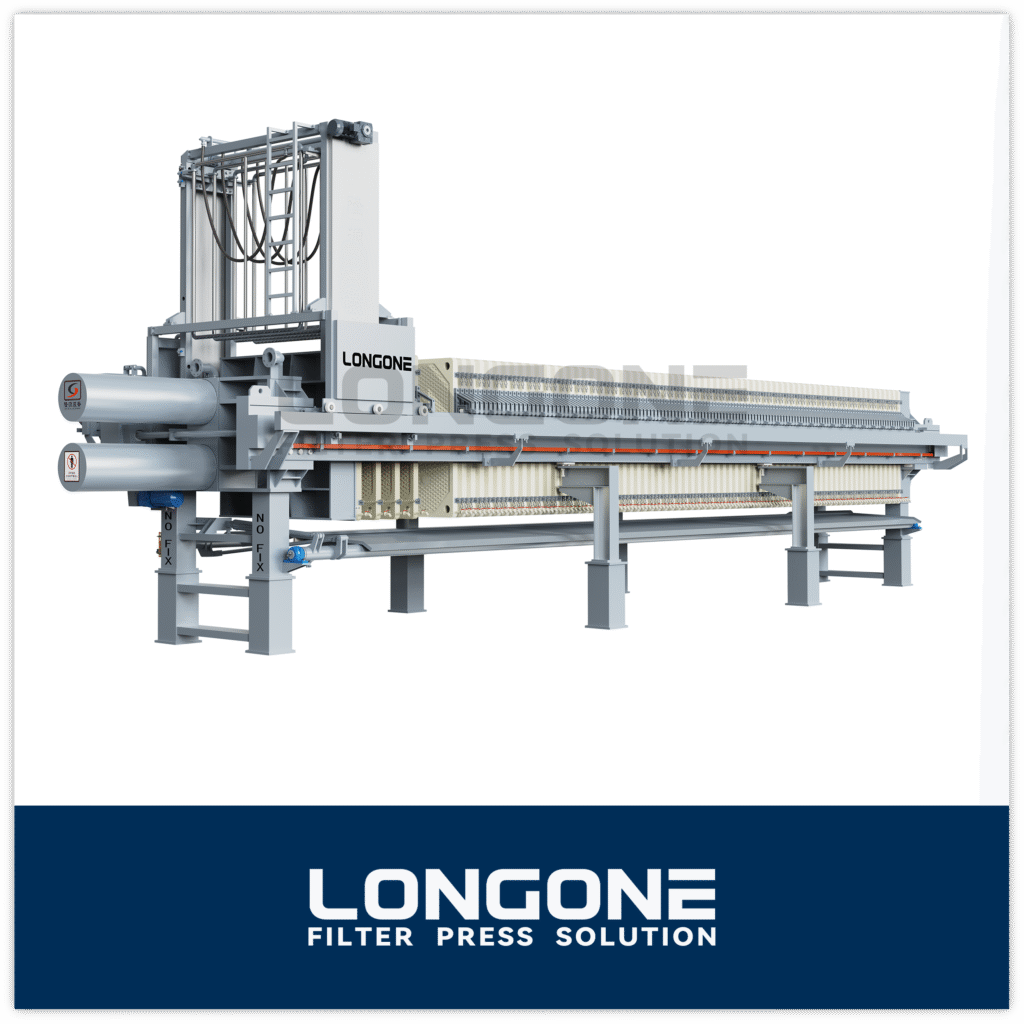

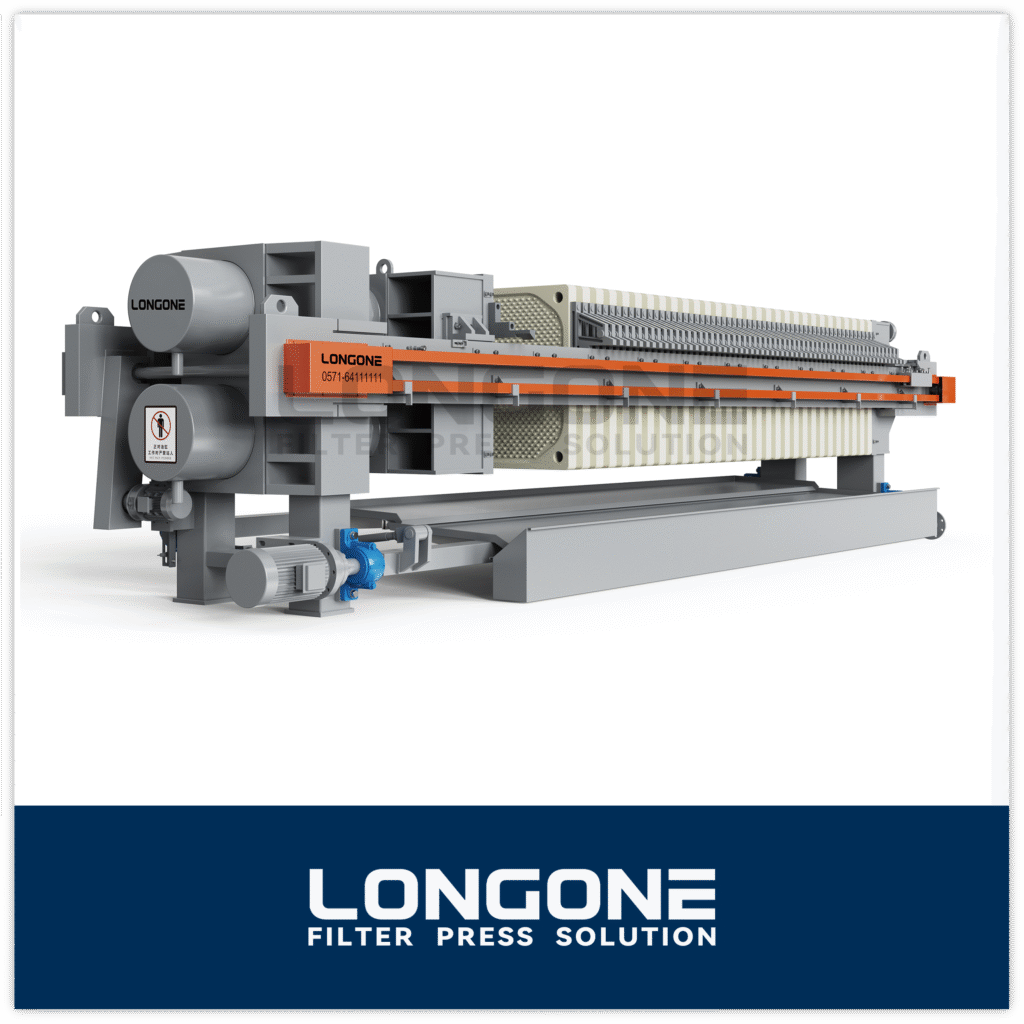

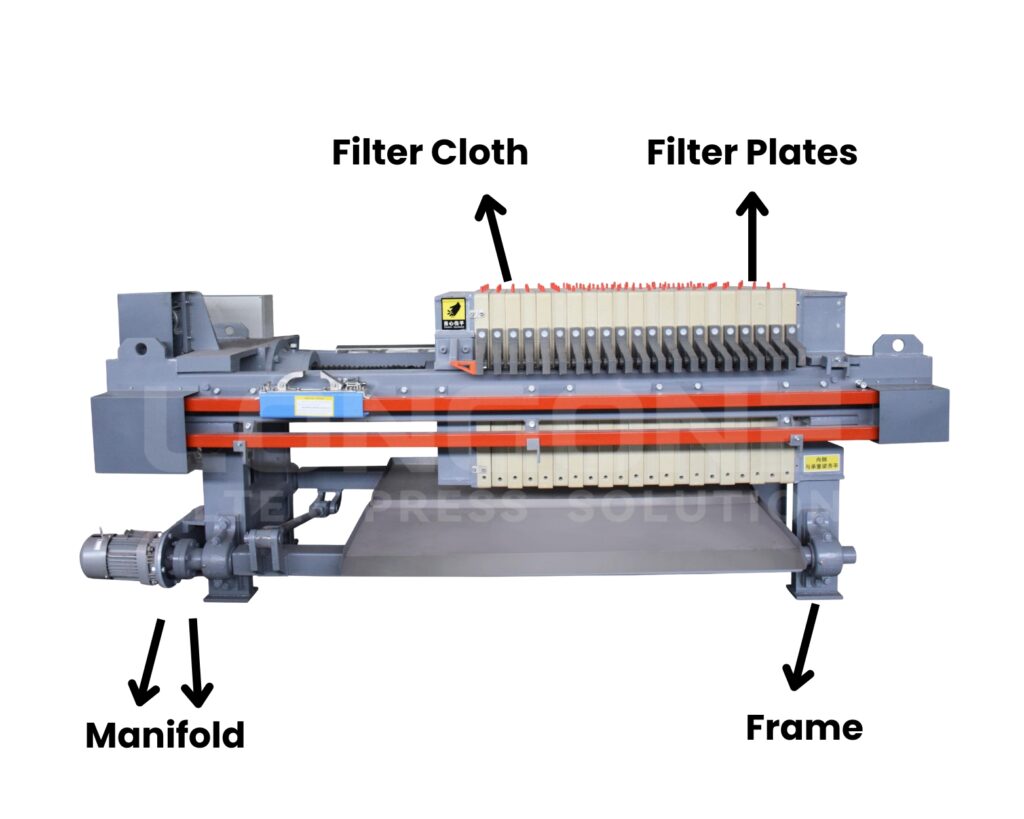

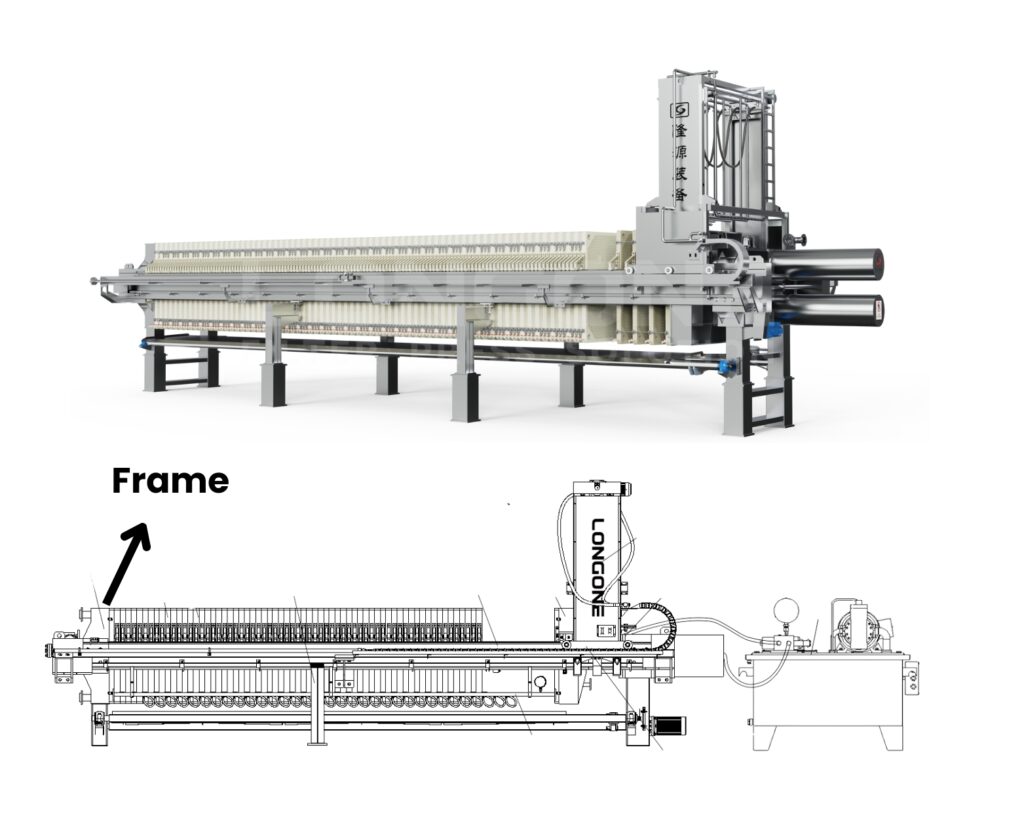

The frame is what holds the filter press together. It has a fixed head, a moving head, and sidebars that hold the filter plates in place and can handle high filtration pressures. A rigid, well-balanced frame makes sure that the pressure is evenly distributed, stops vibrations, and keeps all the plates in line while they are working.

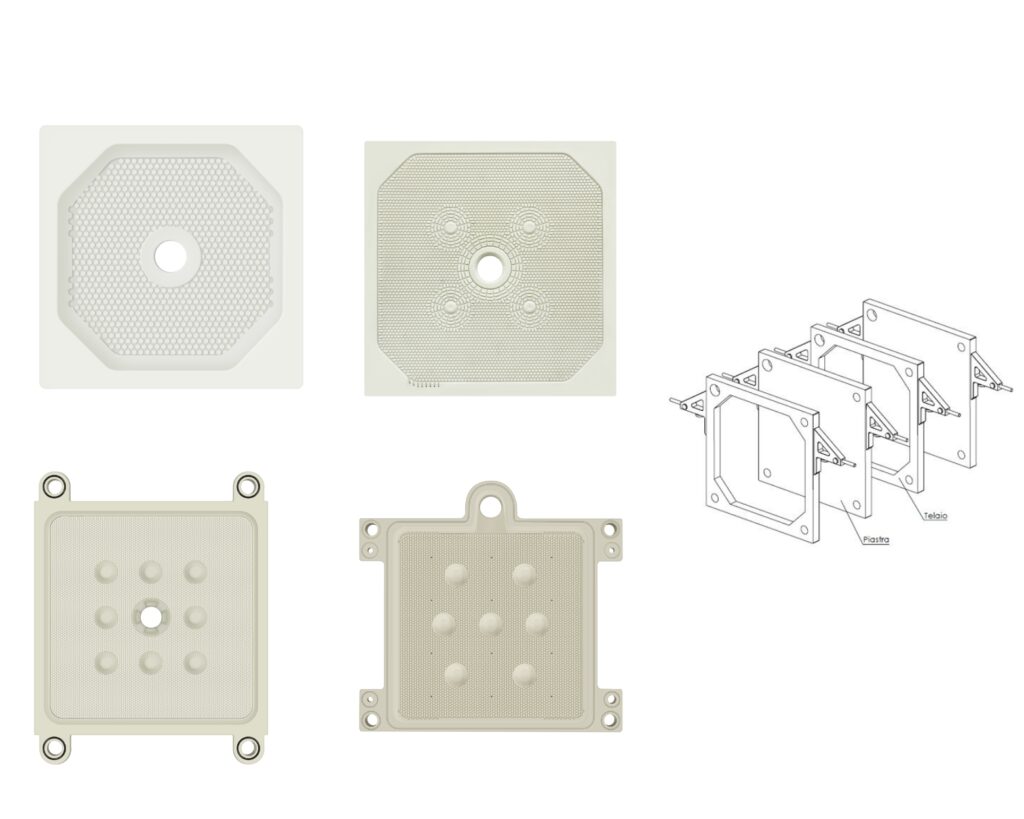

Filter Plates

Filter plates make the filtration chambers and keep the filter cloths in place. The design of the filters affects how well they work, how dry the cake is, and how much they can hold. High-strength polypropylene and stainless steel are the most common materials because they are strong and resistant to chemicals.

- Membrane Filter Plates

These high-tech plates have membranes that can stretch when air or water pressure is applied after the first filtration. The extra squeeze lowers the moisture in the cake, speeds up the cycle time, and increases the throughput. This is great for industries that need to control moisture very precisely.

- Chamber Filter Plates

Chamber plates create sealed chambers between adjacent plates. Slurry enters these spaces, solids accumulate on the cloth, and filtrate exits through discharge channels. This design is simple, efficient, and ideal for general industrial applications.

- Plate and Frame Filter Plates

The classic plate-and-frame setup has plates and frames that switch places, making it easy to clean and check. Even though it’s not as common in big plants these days, it’s still perfect for labs and specialty production lines.

- CGR Plates

CGR plates have a rubber gasket molded around the plate perimeter to prevent leakage. They are the preferred option when processing corrosive or valuable materials requiring absolute containment.

- Custom Filter Plates

Every application has unique requirements. Our company provides custom filter plate design and manufacturing services, including specialized materials, dimensions, and membrane configurations. Whether you need corrosion-resistant stainless steel plates or high-pressure polymer plates, our engineers can tailor solutions to your exact process needs.

(Contact us for detailed specifications or custom drawings.)

Filter Cloth

The filter cloth is the part that filters out solids while letting liquids through. When choosing materials like polypropylene, polyester, or nylon, you should think about how well they work with chemicals, how quickly they filter, and how big the particles are. The right type of cloth makes sure that the cake comes out easily, doesn’t get stuck, and is as clear as possible. Cleaning and replacing things properly are important for long-term performance.

Piping and Valves

The manifold system delivers slurry to the filter chambers and removes filtrate through discharge outlets. Typically made from stainless steel or polypropylene, it includes feed inlets, filtrate outlets, and wash lines controlled by valves. A balanced piping design ensures uniform slurry distribution, smooth discharge, and minimal pressure drop throughout the system.

Hydraulic System

The hydraulic system gives the filter plates the pressure they need to close and seal. It can be manual, semi-automatic, or fully automatic, depending on how it is set up. The hydraulic cylinder pushes the movable head forward, which keeps the plates tight while they are being filtered. Maintaining proper oil quality, seal integrity, and system pressure ensures consistent operation and prevents leakage.

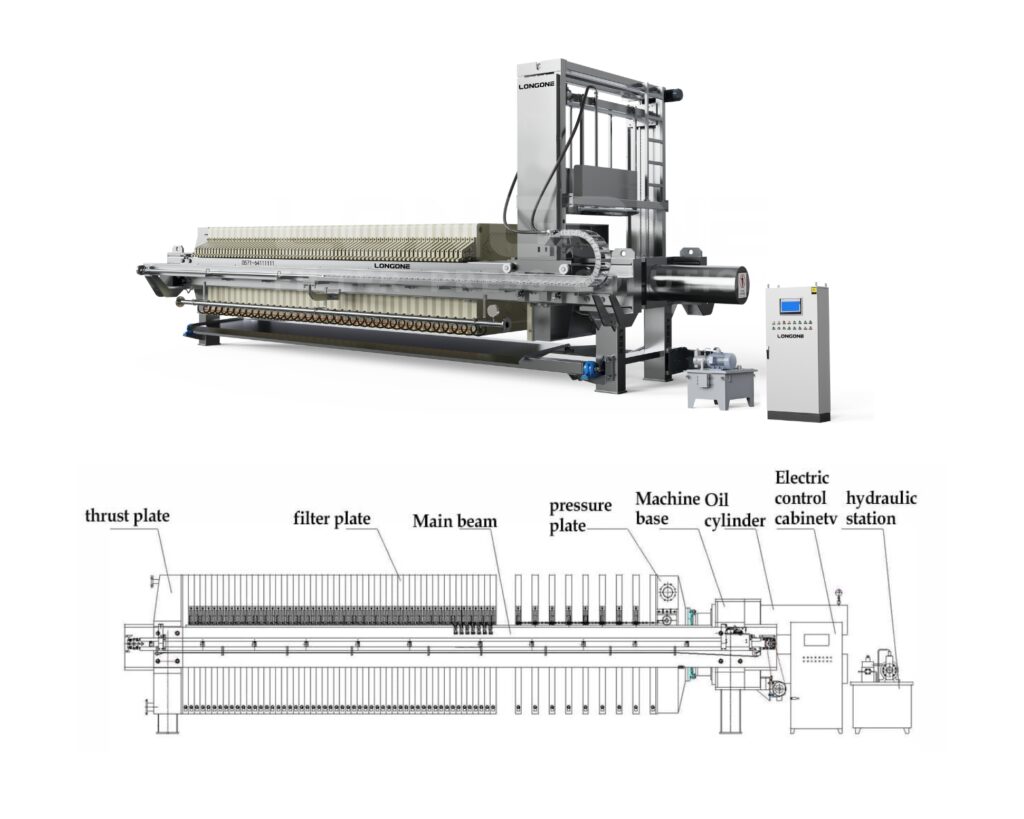

Filter Press Components Diagram

A filter press is a highly integrated system where each component plays a specific role. Below is a summarized list that helps you match the physical diagram with actual parts in the equipment.

| Component | Description / Function | Typical Material |

|---|---|---|

| Frame | Structural support that holds all other components | Carbon steel / Stainless steel |

| Filter Plates | Create chambers for filtration; hold filter cloth | Polypropylene / Stainless steel |

| Membrane Filter Plates | Use air or water pressure to squeeze the cake | PP with rubber membrane |

| Filter Cloth | Retains solids and allows liquid flow | Polypropylene / Polyester |

| Manifold System | Directs slurry and filtrate flow | Stainless steel / PP |

| Hydraulic System | Provides closing and pressing force | Steel cylinder & hydraulic pump |

| Feed Pump | Delivers slurry into the chambers | Diaphragm / Piston pump |

| Control Panel | Automates cycle and safety operations | PLC-based unit |

| Drip Tray & Cake Discharge | Collects filtrate and releases solids | Steel / Polymer coating |

How Filter Press Filtration Works?

The filter press working principle is straightforward yet highly efficient. When filtration begins, slurry is pumped into the filter chambers formed by the plates and cloths.When pressure is applied, the liquid goes through the cloth while the solids stay behind, slowly forming a thick filter cake. As the pressure rises, the moisture is pushed out until the filtrate is clear. The hydraulic system lets go of the plates when the cycle is over, and the cake falls off so it can be picked up. This process can be done over and over again, and it makes sure that the filtrate is clear, the dryness is high, and the machine runs on less energy.

What Are the Applications of Filter Presses in Different Industries?

Filter presses are used wherever solids and liquids must be separated efficiently:

- Wastewater Treatment: Sludge dewatering and water recovery.

- Chemical Processing: Catalyst separation and pigment filtration.

- Food & Beverage: Juice clarification, sugar refining, edible oil filtration.

- Mining and Metallurgy: Metal recovery and tailings management.

- Pharmaceuticals: Sterile filtration and active ingredient recovery.

Their adaptability and component customization make them a preferred choice across diverse industries.

How to Make or Assemble a Filter Press?

Putting together a filter press requires accuracy and proper alignment. The first step is to put the main frame in place and fasten the sidebars. To make sealed chambers, filter plates and cloths are put in place one after the other. Then, the manifold system connects to the feed and discharge lines. The press is ready to use once the hydraulic unit is connected and tested for pressure. A final test makes sure that the plate moves smoothly, seals properly, and doesn’t leak, which are all important steps for long-term reliability.

Maintenance Tips for Filter Press Components

Regular maintenance ensures consistent efficiency and safety. Clean filter cloths to prevent clogging, inspect plates for damage, and check hydraulic oil regularly. Flush the manifold lines, tighten structural bolts, and replace seals or gaskets when worn. Routine preventive care minimizes downtime, reduces energy costs, and extends the life of your filter press components.

Summary

Understanding filter press components—from the frame to the hydraulic system—helps engineers and operators improve filtration efficiency and reliability. With proper maintenance, quality materials, and customized plate designs, your filter press can deliver long-lasting performance and cleaner, drier output across any industrial application.