Filter presses are used in many industries, but few people truly understand how they work.

A filter press works by applying pressure to the material. The slurry is pumped into a chamber made of filter plates. The liquid passes through the filter cloth and exits, while the solids form a dry filter cake inside the chamber. This method efficiently separates solids and liquids.

Understanding how does a filter press works will help you choose the right machine.

What Is The Working Principle Of Filter Press?

The working principle of filter press follows a four-stage cycle that ensures effective solid-liquid separation. These stages—Filling, Filtration, Compression, and Discharge—are designed to maximize filtration efficiency, improve filter cake dryness, and reduce overall operating costs.

Let’s look at each stage in detail:

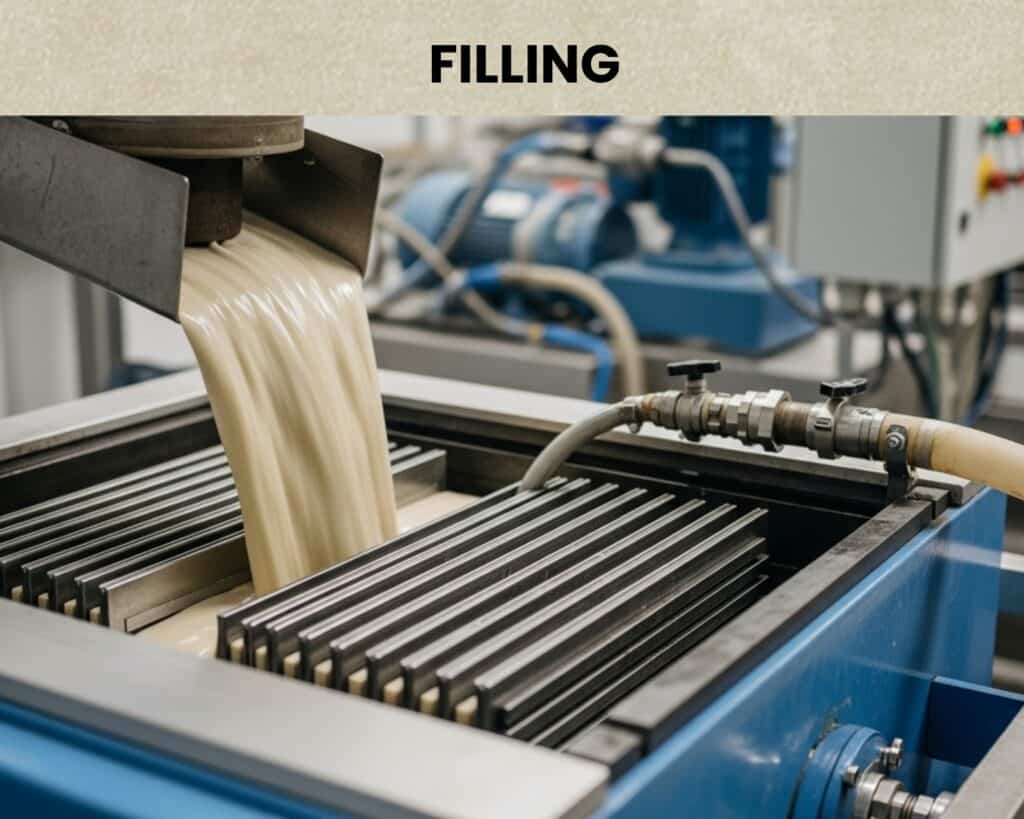

Filling

During the filling phase, the filter press chambers are filled with slurry. To make these chambers, you line up several filter plates and clamp them tightly together. The slurry comes in through a feed inlet and flows evenly into each chamber.

At this point, there are both solid and liquid parts in the chamber, and they are waiting to be separated. The design makes sure that the distribution is even, which prevents pressure imbalances and allows for the best filtration in the next step.

Filling the cake evenly and preventing the filter media from getting partially clogged are both important.

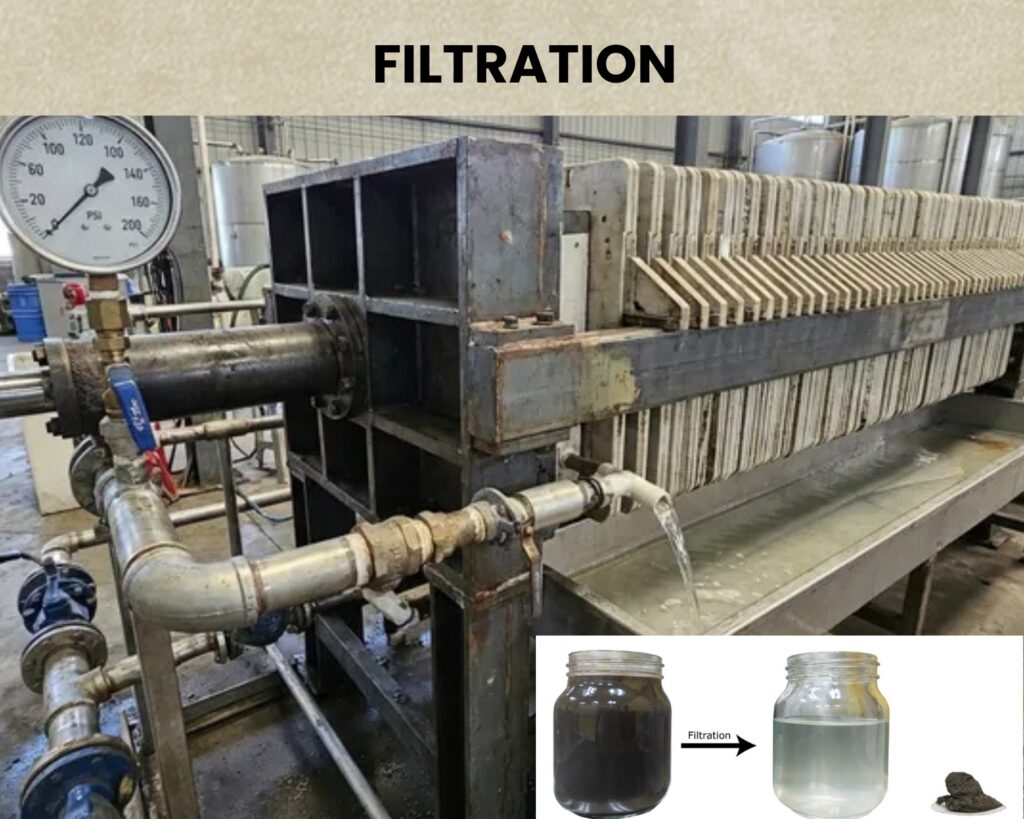

Filtration

The filter cloth on each plate forces the liquid phase through as the slurry fills the chambers. The cloth is a barrier that keeps solids in while letting the clean liquid (filtrate) pass through.

The liquid leaves through drainage ports, leaving behind a layer of solid particles that have been held back. This is the start of the filter cake. This stage goes on until the slurry is completely dry or a certain pressure is reached.

This is the most important part of the process of separating liquids from solids. It is very important for businesses that need high levels of clarity or dry cake output.

Compression (Squeezing)

In advanced systems like a membrane filter press, the compression phase follows the initial filtration. Here, flexible membranes behind the filter cloth inflate using air or water, applying pressure to the filter cake.

This additional pressure squeezes remaining liquid out, significantly reducing the cake’s moisture content. This stage improves both filtration speed and filter cake dryness, which is essential for reducing transport or disposal costs.

Compression is not present in all filter press types but is a key benefit of modern membrane filter press technology.

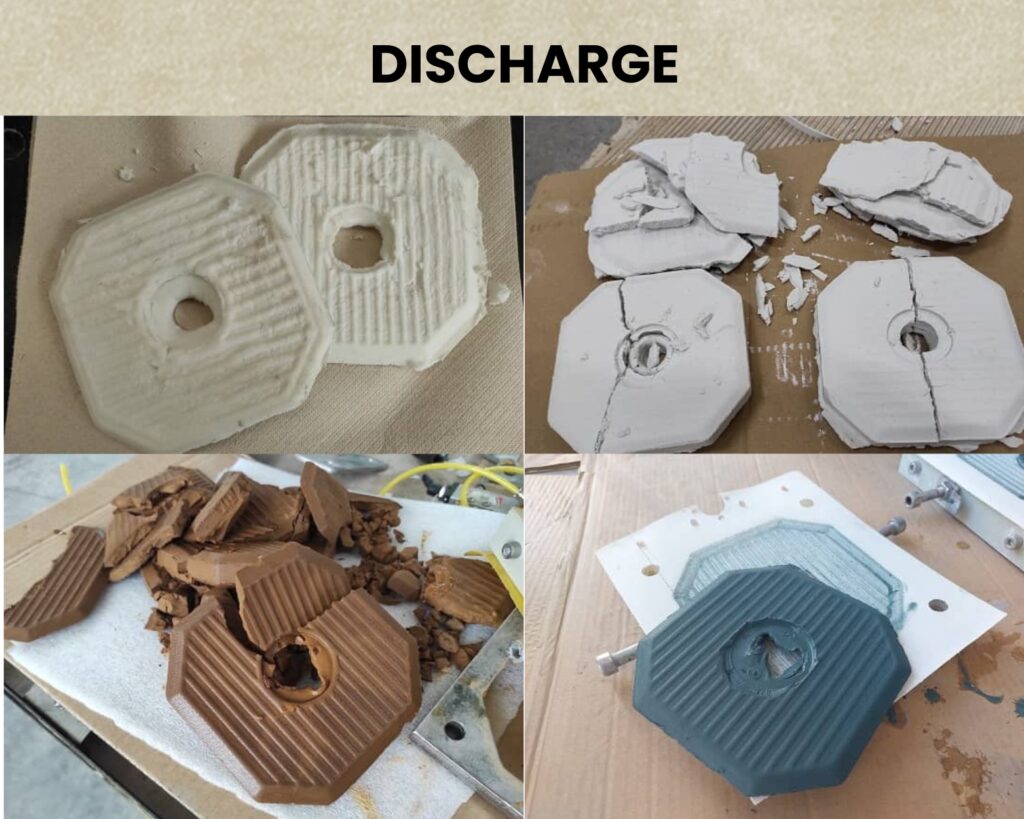

Discharge

Once filtration and compression are complete, the filter press opens. Plates are separated one by one to allow automatic or manual discharge of the filter cakes.

In automated systems, plate shifters and cake fall systems enable fast unloading without human intervention, reducing labor costs and downtime. Cakes typically fall into a conveyor or bin for further processing.

After cake removal, the cloth may be cleaned, and the plates are closed again for the next cycle.

A smooth discharge phase ensures long-term equipment reliability and stable production output.

What Is A Filter Press Used For?

Filter presses are used across a wide variety of industries that demand efficient solid-liquid separation. Some of the most common applications include:

- Mining and Mineral Processing: Recover fine particles and recycle process water.

- Chemical Manufacturing: Purify fluids or recover valuable solids.

- Municipal Wastewater Treatment: Dewater sludge before transportation or landfill.

- Food & Beverage: Clarify juices, oils, and other food-grade liquids.

These applications benefit from a filter press’s ability to produce low-moisture filter cakes and minimize liquid loss.

Works well in industries that need to separate solids from liquids.

What Are The Disadvantages Of Filter Press?

Despite their advantages, filter presses can come with certain limitations:

- Long Cycle Times: Especially for large volumes or fine particle slurries.

- Labor Intensity: Manual systems require more handling.

- Cleaning & Maintenance: Filter cloths need frequent cleaning or replacement.

Fortunately, modern automatic filter press designs overcome many of these problems through:

- Automated plate shifting and cake discharge

- Cloth washing systems

- Programmable cycle control

Additionally, custom filter press solutions can be tailored for specific materials, reducing inefficiencies.

Automation addresses most of the downsides.

What Is The Working Principle Of Plate And Frame Filter Press?

The plate and frame filter press is a classic design that uses plates and frames that alternate to make chambers. Slurry flows into the frames, where solids build up, and liquid flows through filter cloth on the plates next to it.

This type is often used in labs or small batch operations where being able to see, control, or get to the machine is important.

It’s not used as much these days, but it’s still useful when low throughput and flexibility are more important than automation.

Great for basic or small-scale filtering needs.

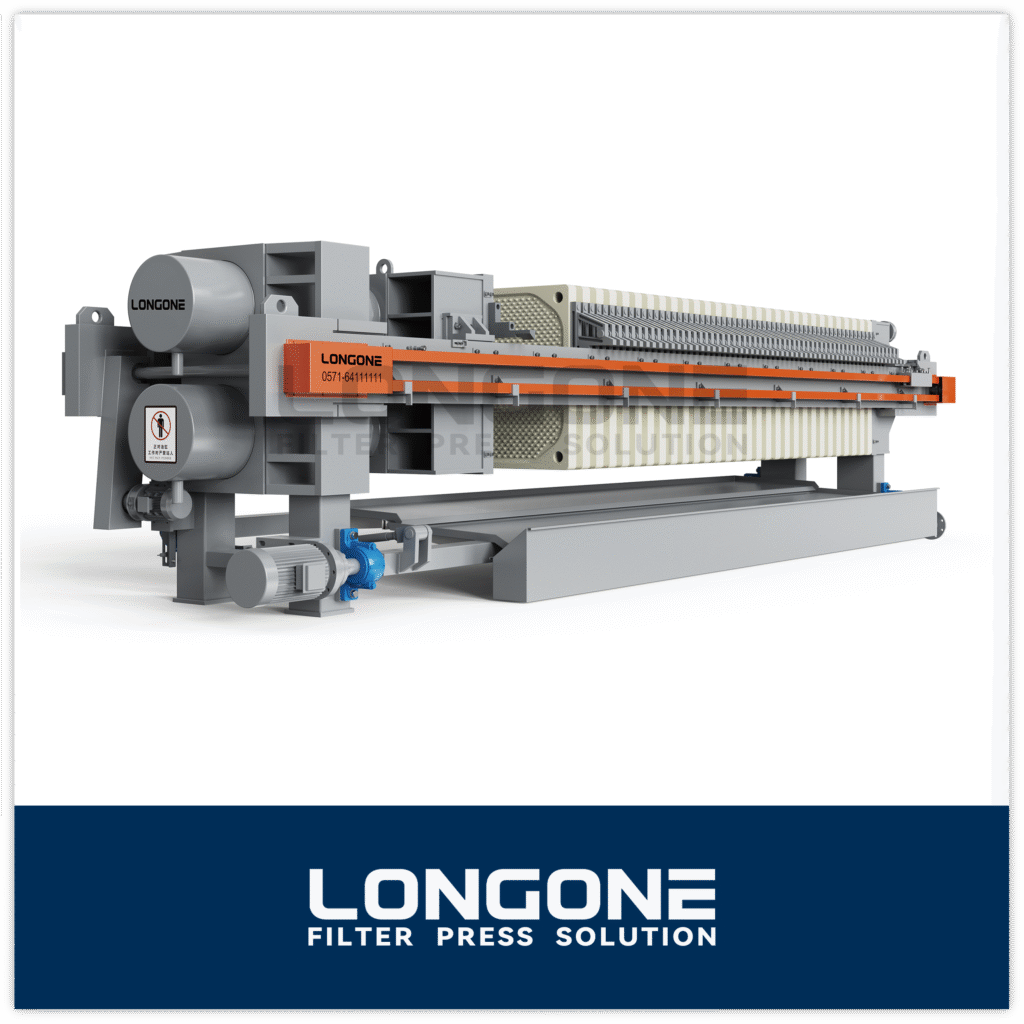

How Does A Membrane Filter Press Work?

A membrane filter press goes beyond regular filtration by using squeezing technology. After the filtering stage, air or water is used to compress the cake and make the membranes bigger.

This extra pressure makes the cakes much drier and speeds up the cycles. The outcome is:

- Higher throughput

- Lower disposal volume

- Reduced post-treatment costs

Membrane filter presses are great for industries like metallurgy, pharmaceuticals, and food waste treatment where keeping the filter cake dry is very important.

In short, it’s best for dry filter cakes and faster cycles.

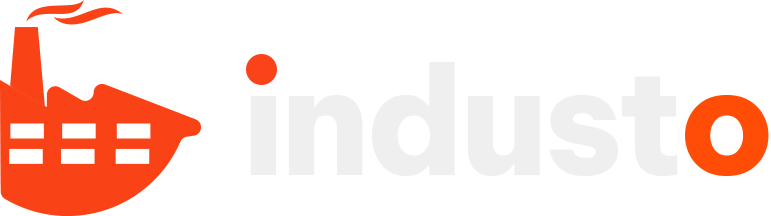

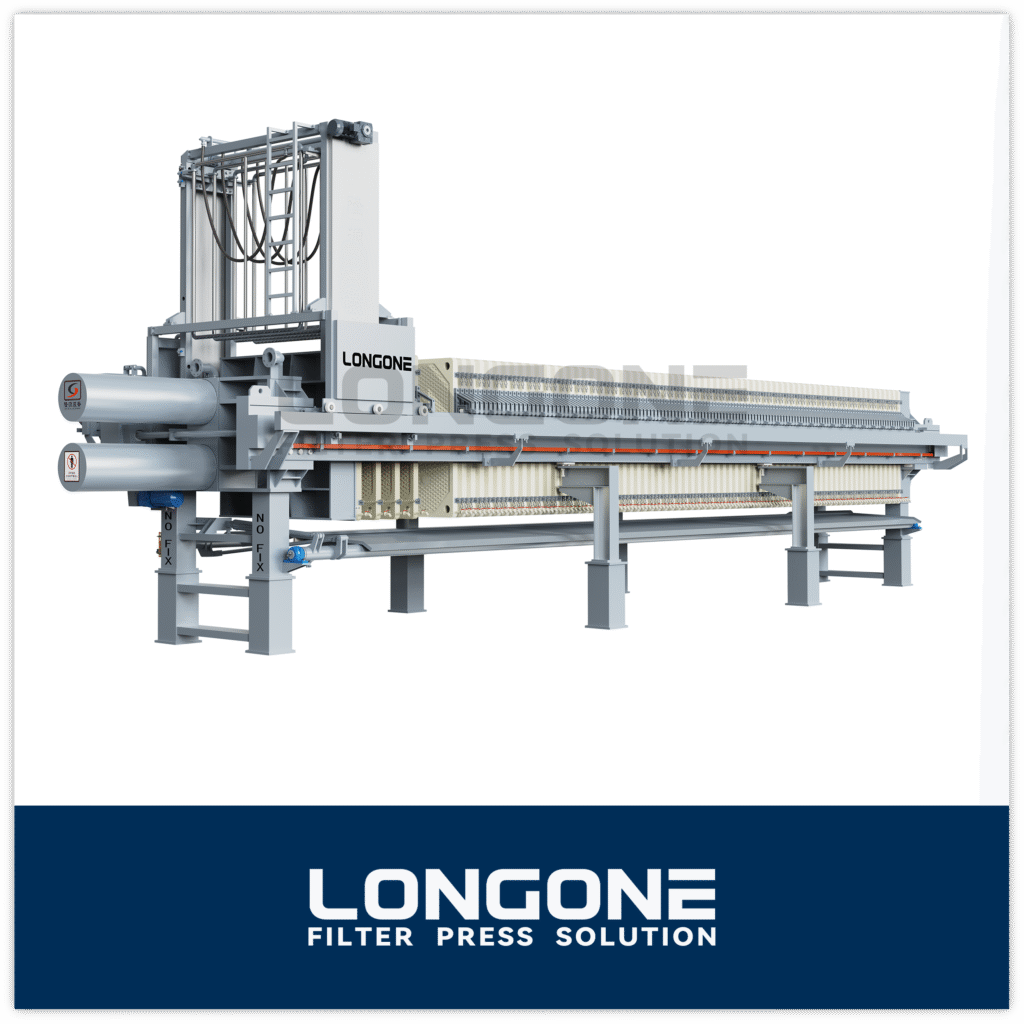

How Does A Chamber Filter Press Work?

The chamber filter press has recessed plates that make evenly spaced filtration chambers. These chambers are filled with slurry, and the cloth lining lets the liquid through while keeping the solids inside.

It is favored for:

- High-pressure capacity

- Robust structure

- Continuous, stable operation

Modern chamber presses also support automatic cake discharge, reducing labor and improving efficiency in large-scale operations like wastewater treatment or mining.

Reliable, rugged, and suited for heavy-duty use.

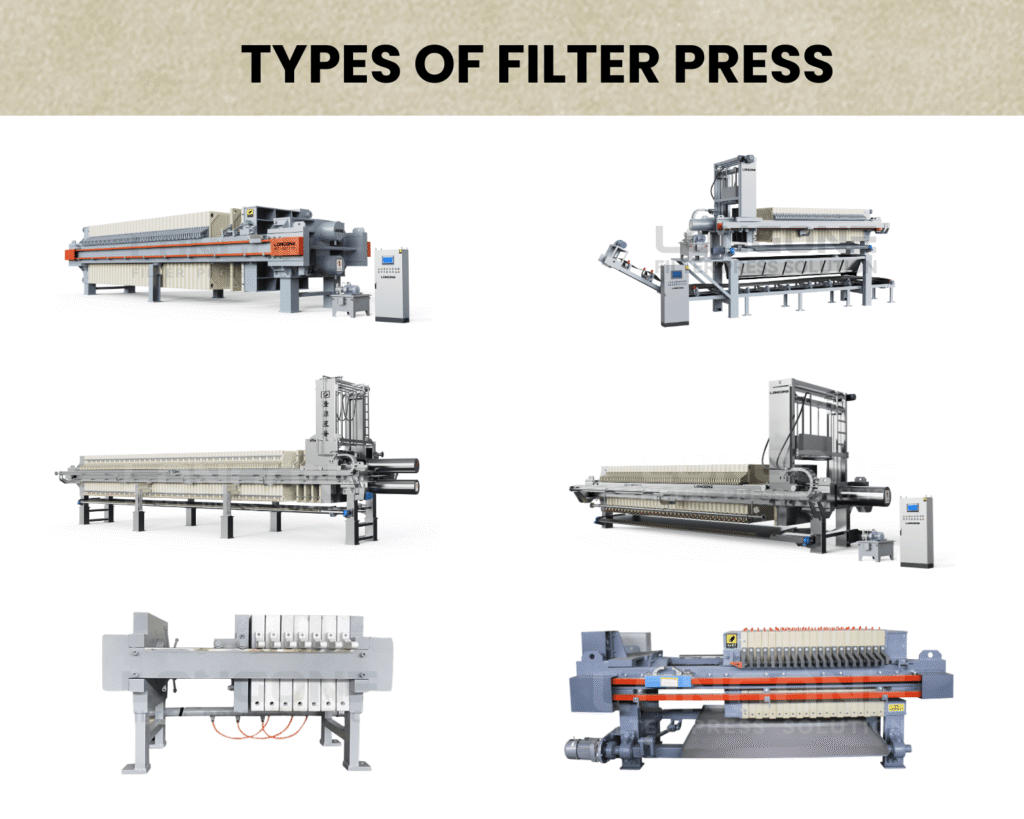

How To Choose The Right Type Of Filter Press?

Selecting the right filter press involves evaluating your process needs:

Slurry characteristics: Is it fine, abrasive, or high in solids?

Required dryness: Need ultra-dry cakes? Choose a membrane filter press.

Cycle speed: Automatic filter presses shorten turnaround time.

Labor availability: Consider full automation if labor is limited.

Custom requirements: Go for a customized filter press system.

Working with a supplier who offers consultation and flexible design ensures you get a solution tailored to your industry and application.

Match press type with process demands.

Conclusion

Understanding the four-stage working principle—Filling, Filtration, Compression, and Discharge—is key to optimizing performance and choosing the right filter press for your operation.