Are you having trouble with inconsistent filtration results? Poor solid-liquid separation can cause costly downtime. Choosing the right filter press will make sure that it works well and costs less to run.

A filter press is an industrial filtration system used for high-efficiency solid-liquid separation. It operates by applying pressure through filter plates and cloths to produce dry cakes and clear filtrate. Different types of filter presses—such as membrane, chamber, or automatic designs—fit various industrial needs, from wastewater treatment to chemical processing.

Let’s explore the main types of filter presses and find which best fits your industrial process.

What Is a Filter Press?

A filter press is one of the best machines for separating liquids and solids in factories. It has a series of filter plates with cloths on them that catch solids while letting liquids through.

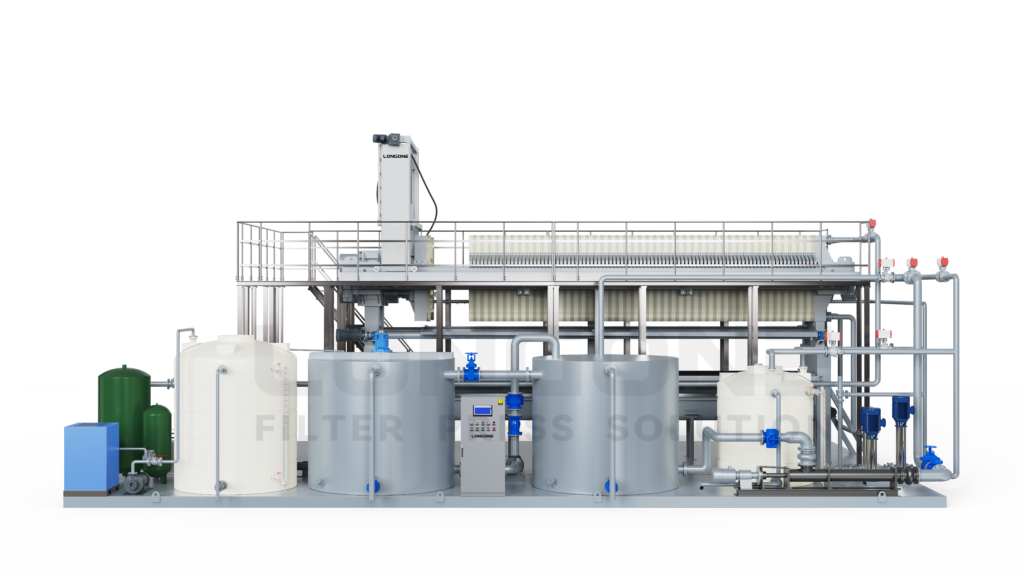

The filter press is a common tool in industrial filtration for treating wastewater, mining, chemicals, and food processing. It separates solids and liquids very well and lowers disposal costs. Because it is modular, it can be easily changed to fit different needs, making it a flexible solution for many industries.

Any process that needs clear filtrate and dry solid output needs a filter press.

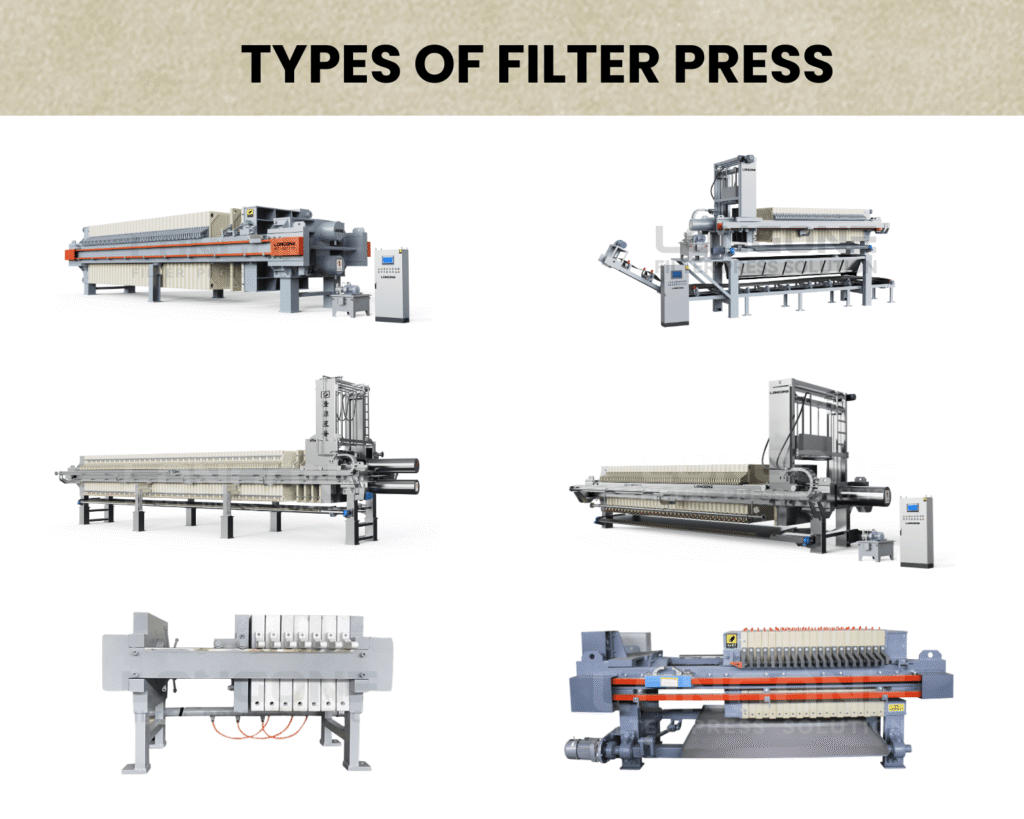

Common Filter Press Types

There are many different types of filter presses to meet different filtration needs. For quick reference, the table below compares their main features, uses, and benefits.

| Type of Filter Press | Main Advantages | Typical Applications | Structure & Working Principle |

|---|---|---|---|

| Membrane Filter Press | Extra squeezing for lower cake moisture, short cycle time | Chemical, pharmaceutical, food industries | Uses flexible membranes to apply secondary compression on the cake after filtration. |

| Frame and Plate Filter Press | Simple, low cost, easy maintenance | Laboratory, pilot projects, small wastewater treatment | Alternating plates and frames create filter chambers for small-scale filtration. |

| Sludge Filter Press | Handles high solids content, strong structure | Municipal & industrial wastewater treatment | Uses high-pressure filtration to dewater sludge efficiently. |

| Automatic Filter Press | Fully automated, minimal labor | Mining, chemicals, large wastewater systems | Equipped with hydraulic + PLC control for continuous operation. |

| Stainless Steel Filter Press | Corrosion-resistant, hygienic | Food, beverage, pharmaceutical industries | Stainless construction prevents contamination and withstands aggressive chemicals. |

| Laboratory Filter Press | Compact, precise testing | R&D, university labs, pilot plants | Miniature design simulates industrial filtration for test runs. |

| Chamber Filter Press | Most common, stable operation, easy automation | Mining, metallurgy, chemical processing | Alternating plates form sealed chambers for efficient slurry dewatering. |

Membrane Filter Press

The membrane filter press uses flexible membranes to put more pressure on the filter cake.

Pros: It removes water quickly, leaves less moisture in the cake, and has shorter filtration cycles.

Uses: Great for the chemical, pharmaceutical, and food industries that need very precise filtration.

Structure and How It Works: The membrane fills with air or water after the chamber is full, which compresses the cake to make it as dry as possible.

Best for businesses that need the filter cake to be as dry as possible.

Frame and Plate Filter Press

The oldest and simplest kind of filter press, it has alternating plates and frames that make filter chambers

Pros: inexpensive, easy to care for, and good for small-scale uses.

Uses: testing in the lab, pilot filtration, and small wastewater projects.

Structure and working principle: Slurry flows into each frame, solids collect on the plate, and filtrate flows out through the outlet.

Great for small or test filtration systems.

Sludge Filter Press

Sludge Filter Press

Designed to handle thick, heavy sludge from municipal and industrial wastewater systems.

Advantages: Strong structure, high-pressure resistance, automatic cake discharge.

Applications: Common in wastewater treatment and environmental engineering.

Structure & Working Principle: Sludge is pumped into chambers, water is removed under high pressure, forming compact, easy-to-handle cakes.

Perfect for dewatering heavy sludge efficiently.

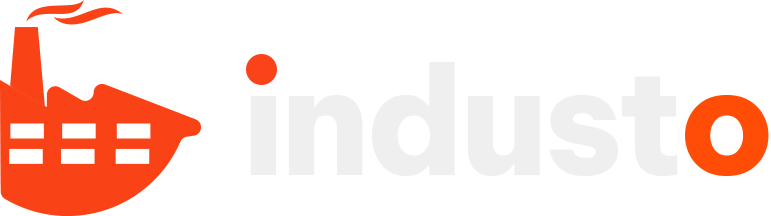

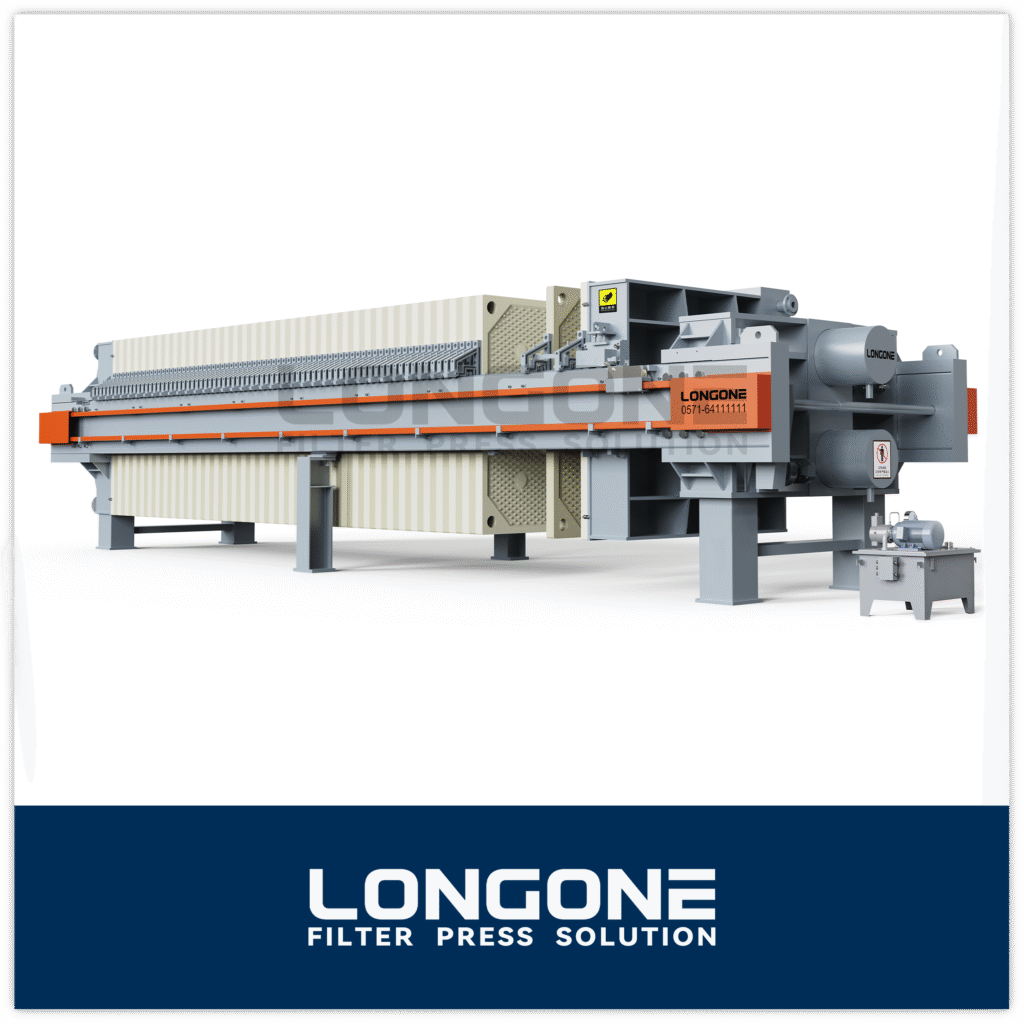

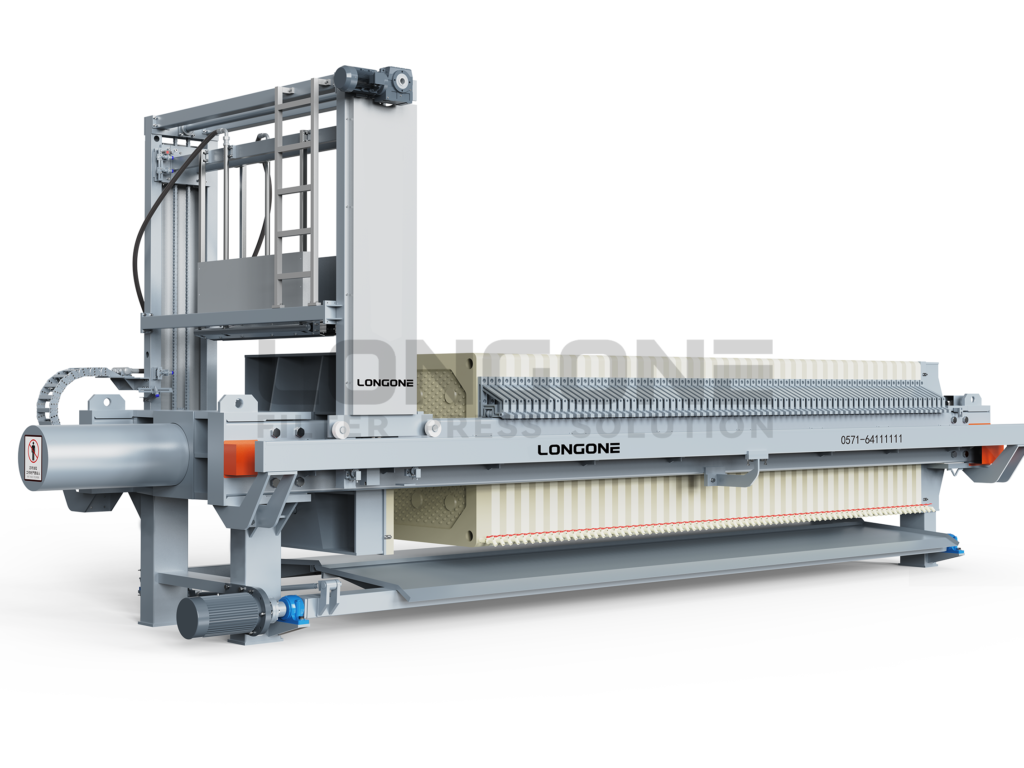

Automatic Filter Press

A system that is fully automated and takes care of pressing, moving plates, and getting rid of cakes.

Pros: Less work, consistent quality, and the ability to work from a distance.

Uses: chemical plants, mining, and places that treat industrial wastewater.

Structure and Working Principle: It has hydraulic and PLC control, which lets it run continuously without anyone having to watch it.

In short, this is great for big, continuous production lines.

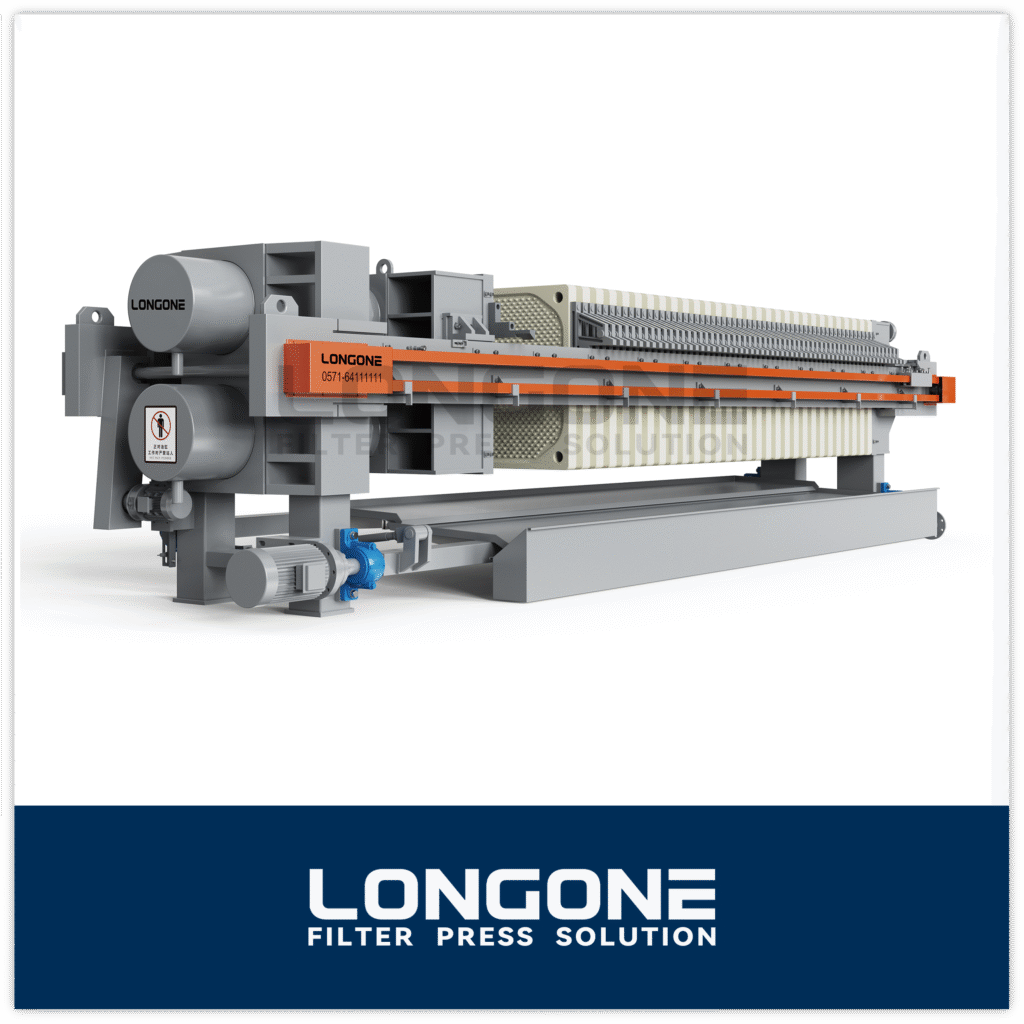

Stainless Steel Filter Press

Built from corrosion-resistant stainless steel for hygienic and chemical applications.

Advantages: Long service life, easy cleaning, and excellent resistance to aggressive chemicals.

Applications: Food & beverage, pharmaceutical, and fine chemical industries.

Structure & Working Principle: Similar to a chamber press but constructed with stainless components to prevent contamination.

Designed for clean or corrosive environments.

Laboratory Filter Press

A small model used for research and testing filtration on a small scale.

Benefits: You can control the filtration parameters very precisely, and you only need a small amount of sample.

Uses: research and development departments, colleges and universities, and pilot filtration tests.

Structure and Working Principle: A small plate and frame structure that mimics industrial processes.

In short, this is the best way to test filter media and improve processes.

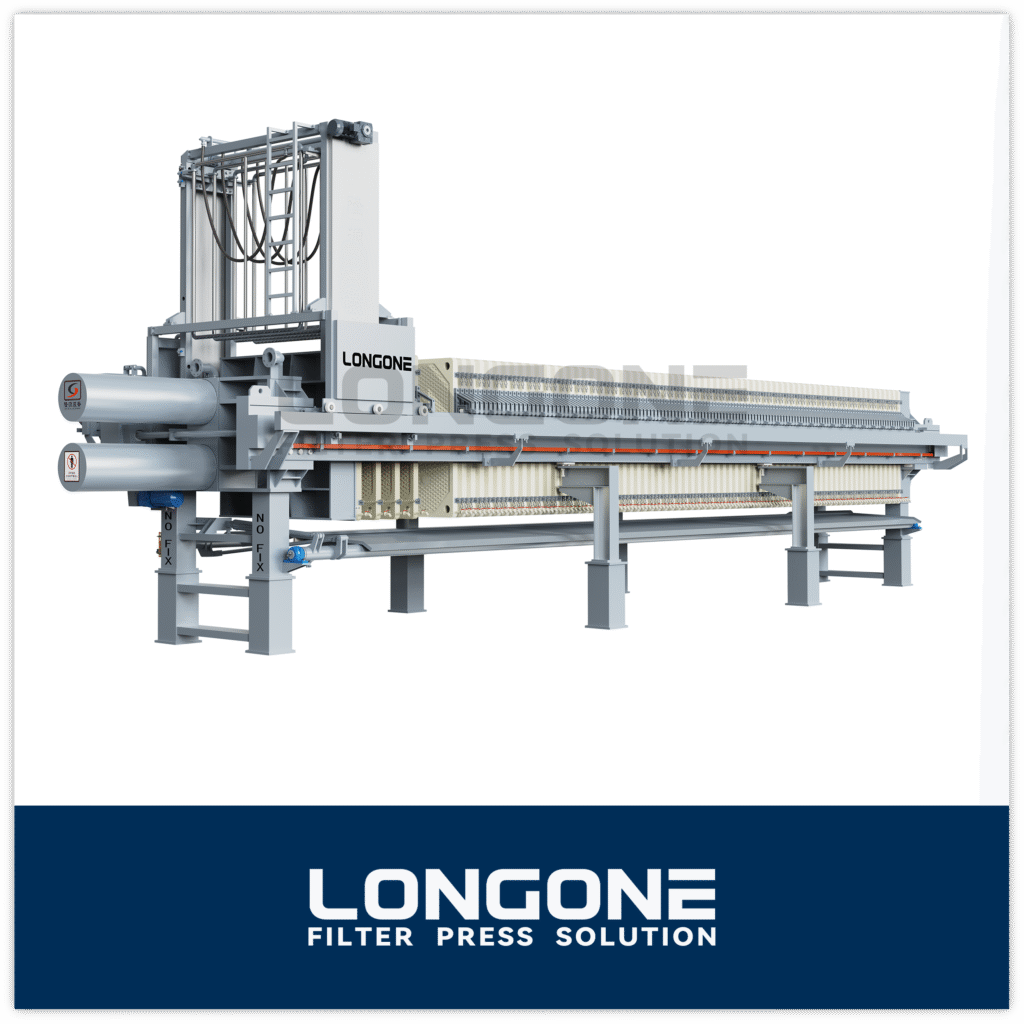

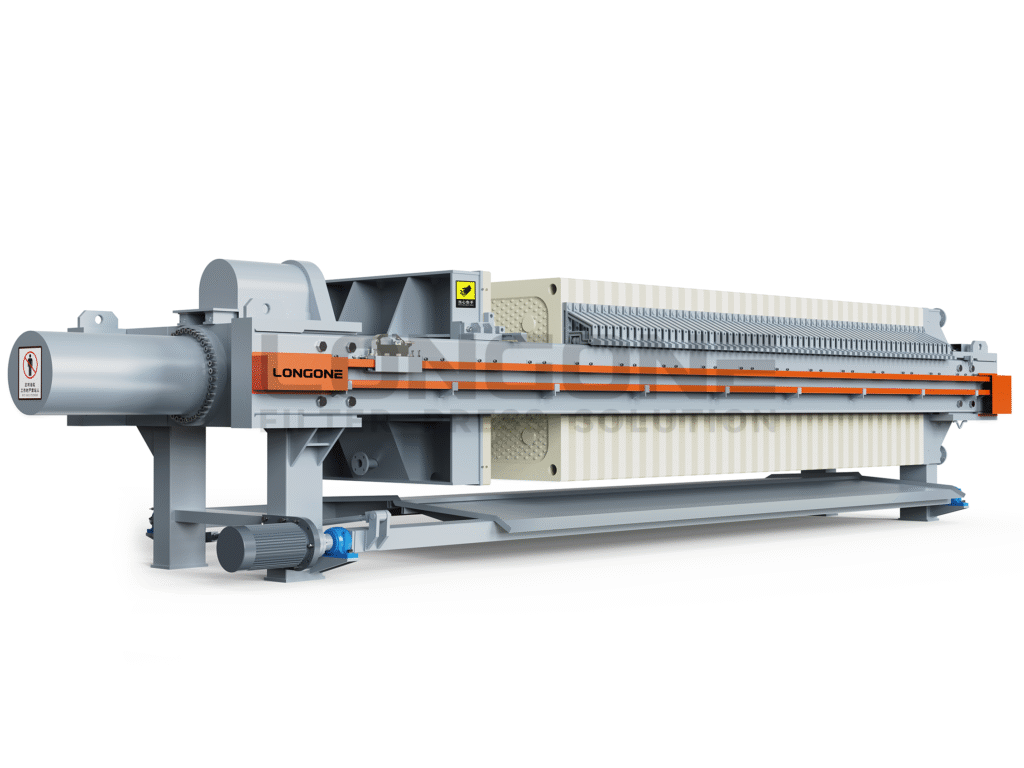

Chamber Filter Press

The most widely used type in industrial filtration.

Advantages: Stable performance, simple design, easy automation.

Applications: Mining, chemical, and metallurgical sectors.

Structure & Working Principle: Alternating plates form closed chambers where slurry is pumped; solids stay, filtrate flows out.

The most cost-effective and popular industrial filter press design.

What Is the Working Principle of a Filter Press?

A filter press works in a cycle: it fills, filters, presses, and empties. Slurry goes into each chamber, and solids build up on the cloth to make a cake. Mechanical or hydraulic pressure pushes out the liquid, leaving behind dry solids. When they are done, the plates separate and the cakes come out.

This process guarantees very efficient solid-liquid separation, making it perfect for custom filtration solutions in all fields.

In short, filter presses use pressure to separate clear liquids from solid particles.

Find the Perfect Filter Press for Your Filtration Processes

Choosing the right industrial filter press depends on your slurry characteristics, cycle time, and automation needs.

At Longone Corporation, we specialize in customized filtration solutions—from membrane to automatic filter presses—engineered for optimal performance in wastewater treatment, mining, and chemical processing.

Our systems offer robust construction, high automation, and long-term reliability, helping you reduce downtime and operation costs.

Contact us at info@longonefiltra.com

to find the best filter press for your project.

Summary

There are different kinds of filter presses for different industries, from small lab units to fully automatic systems. You can choose the best equipment for your process if you know what they are and how they work. Longone helps you get high-efficiency solid-liquid separation by making custom designs and giving you expert help.

FAQ

Q1:What is the best filter press for cleaning up wastewater?

A chamber or membrane filter press is best for industrial wastewater because it makes dry cakes and is easy to use.

Q2: How often do you need to take care of a filter press?

It is best to check every 3 to 6 months, which should include cleaning the plates and checking the hydraulics.

Q3: Can filter presses deal with materials that corrode?

Yes. You can safely use aggressive chemicals with a stainless steel filter press or plates that won’t rust.

Q4: What makes the time it takes to filter?

The thickness of the cake, the pressure of the feed, and the concentration of the slurry all affect how long the cycle lasts.

Q5: Does Longone make custom designs?

Of course. Longone makes custom filtration solutions for a wide range of industries and process needs.