- Specifically engineered to integrate seamlessly with LONGONE filter press systems for continuous, automated material handling.

- High-capacity conveying up to 4130 m³/h ensures efficient sludge, cake, and bulk material transportation.

- Customizable belt width, length, and speed to match filter press size and site layout.

- Low energy consumption, minimal wear, and 24/7 operation reduce maintenance costs and downtime.

Designed for Seamless Integration with LONGONE Filter Presses

LONGONE belt conveyor systems are developed as dedicated accessories for our filter press machines, enabling smooth and uninterrupted material transfer before and after filtration.

When integrated with a filter press system, the belt conveyor:

-Ensures continuous feeding and discharge of filter cakes

-Reduces manual handling and downtime

-Enhances dewatering efficiency and plant productivity

The conveyor dimensions, structure, and capacity are precisely matched to the size, output, and operating conditions of the filter press.

Key Features & Advantages

- Continuous and automated conveying for stable material flow

- High conveying efficiency with low energy consumption

- Horizontal and smooth transport, minimizing material loss

- Fully automatic emptying with minimal wear

- 24/7 continuous operation, suitable for heavy-duty industrial use

- Low maintenance cost and long service life

- Modular design, flexible and reliable for different layouts

- Compliant with IS 11592 and CEMA standards

Technical Specifications

| Parameter | Specification |

|---|---|

| Belt Width | 500 – 1400 mm |

| Belt Strength (Fabric) | Cotton canvas: 56 N/mm/layer |

| Nylon / PET woven belt: 100–300 N/mm/layer | |

| Steel Cord Belt Strength | ST630 – ST2000 N/mm |

| Belt Speed | 0.8 / 1.0 / 1.25 / 1.6 / 2.0 / 2.5 / 3.15 / 4.0 / 5.0 m/s |

| Max Conveying Capacity | Up to 4130 m³/h |

Customizable Conveyor Design

LONGONE belt conveyors provide a wide range of customization options to accommodate various filter press configurations and throughput requirements:

-Belt width: 500–1400 mm

-Belt length: Adaptable to the layout of the site

-Various arrangements for internal transport, feeding, and discharge

-Many accessories are available for particular uses.

Customers can choose the best conveyor model based on material properties and production requirements thanks to this flexibility.

Send Your Inquiry Today

LONGONE belt conveyor Supplier

As a specialist supplier of belt conveyors for filter press systems, LONGONE creates belt conveyors that are precisely engineered to operate in perfect harmony with our filter presses. These conveyors are designed to facilitate constant feeding and discharge, guaranteeing steady, automated material flow during the dewatering procedure. Operators can greatly reduce manual handling, increase production efficiency, and maintain a cleaner working environment by integrating the belt conveyor directly into the filter press system.

LONGONE belt conveyors are ideal for transporting filter cake, wet sludge, and other bulk materials after filtration. Each conveyor is customized according to filter press size, throughput requirements, and site layout, ensuring optimal performance and long-term reliability. With high conveying capacity, low energy consumption, and robust construction, our belt conveyors provide a cost-effective and durable solution for industrial and municipal dewatering applications.

Looking for a belt conveyor perfectly matched to your filter press system?

Contact LONGONE today to discuss your application requirements. Our engineering team will provide professional recommendations and customized conveying solutions to optimize your filtration and material handling process.

Send Your Inquiry Today

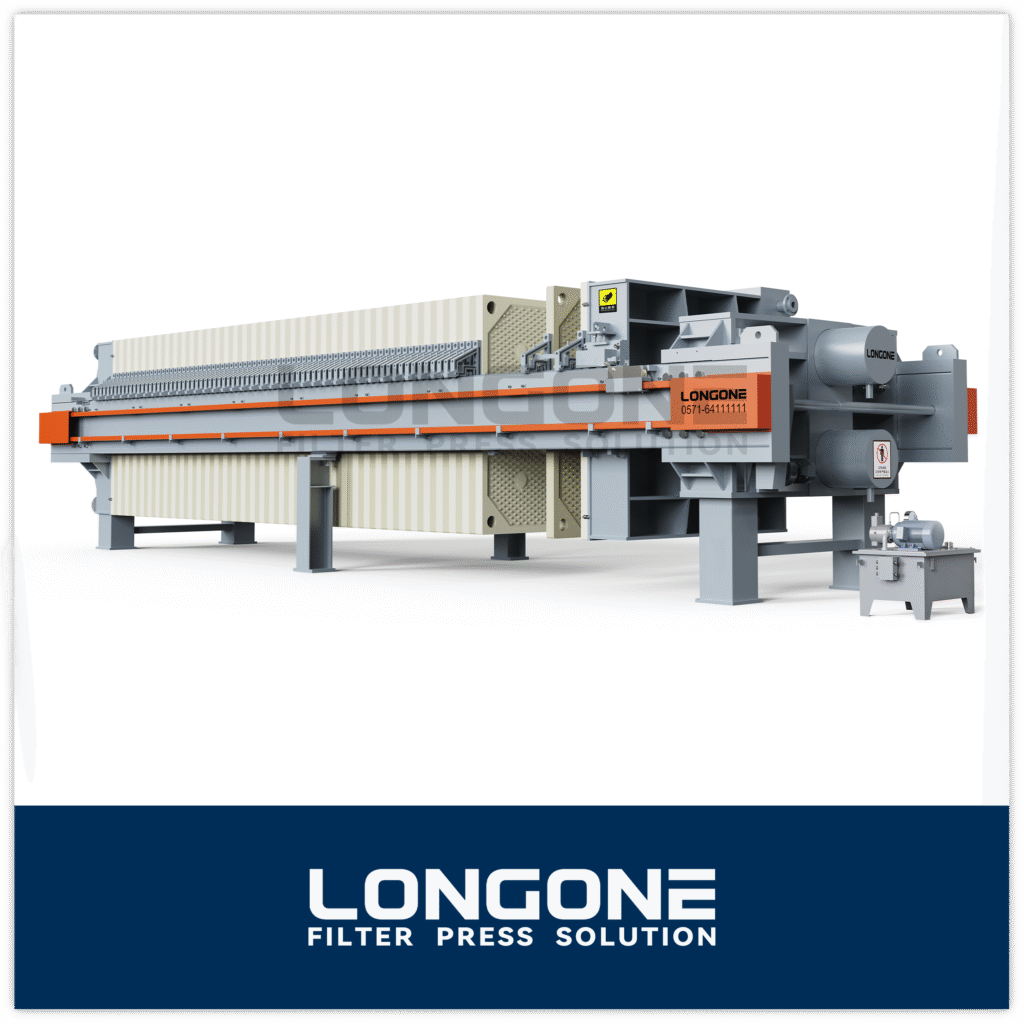

Related products

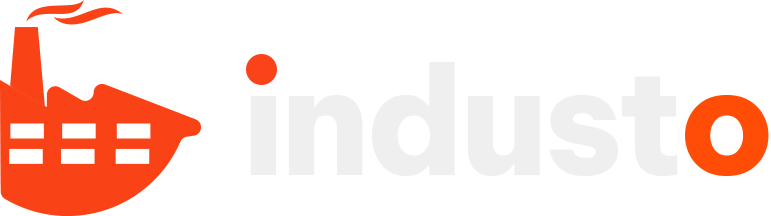

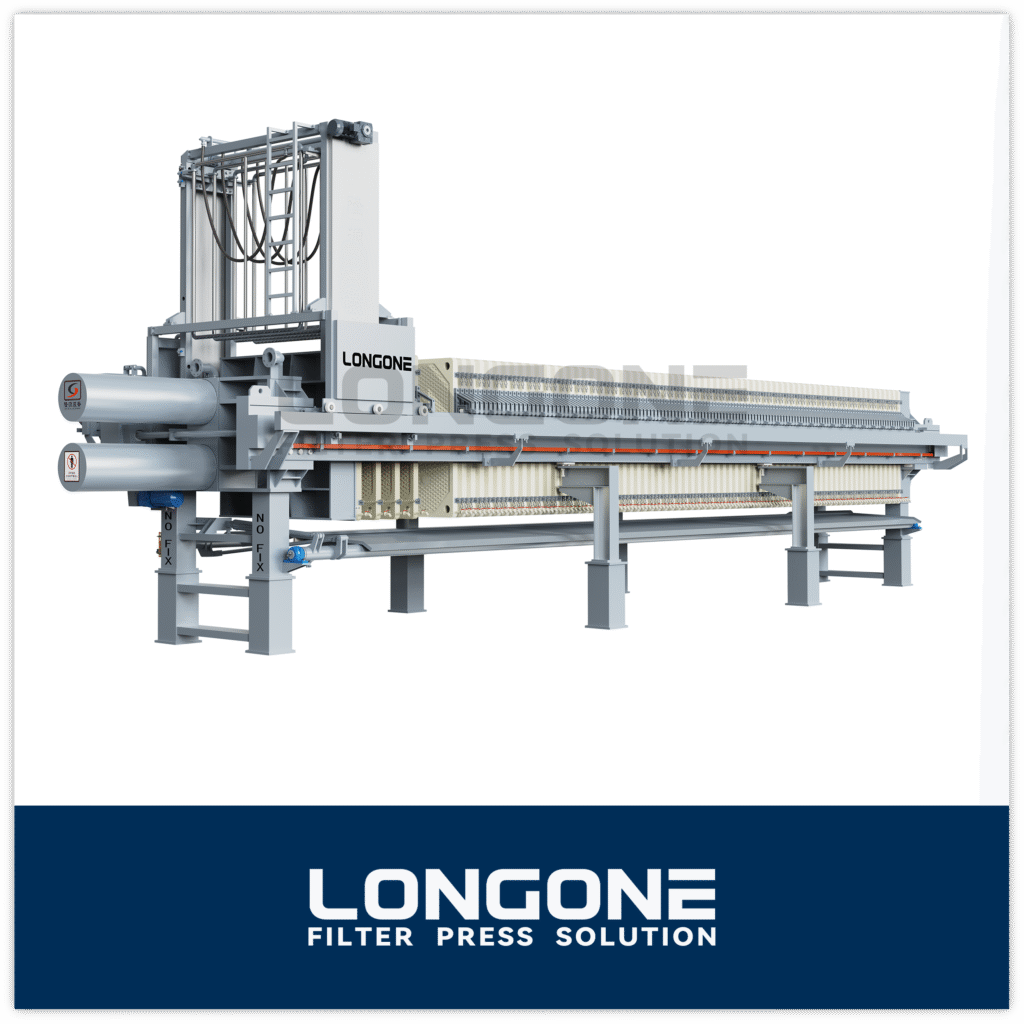

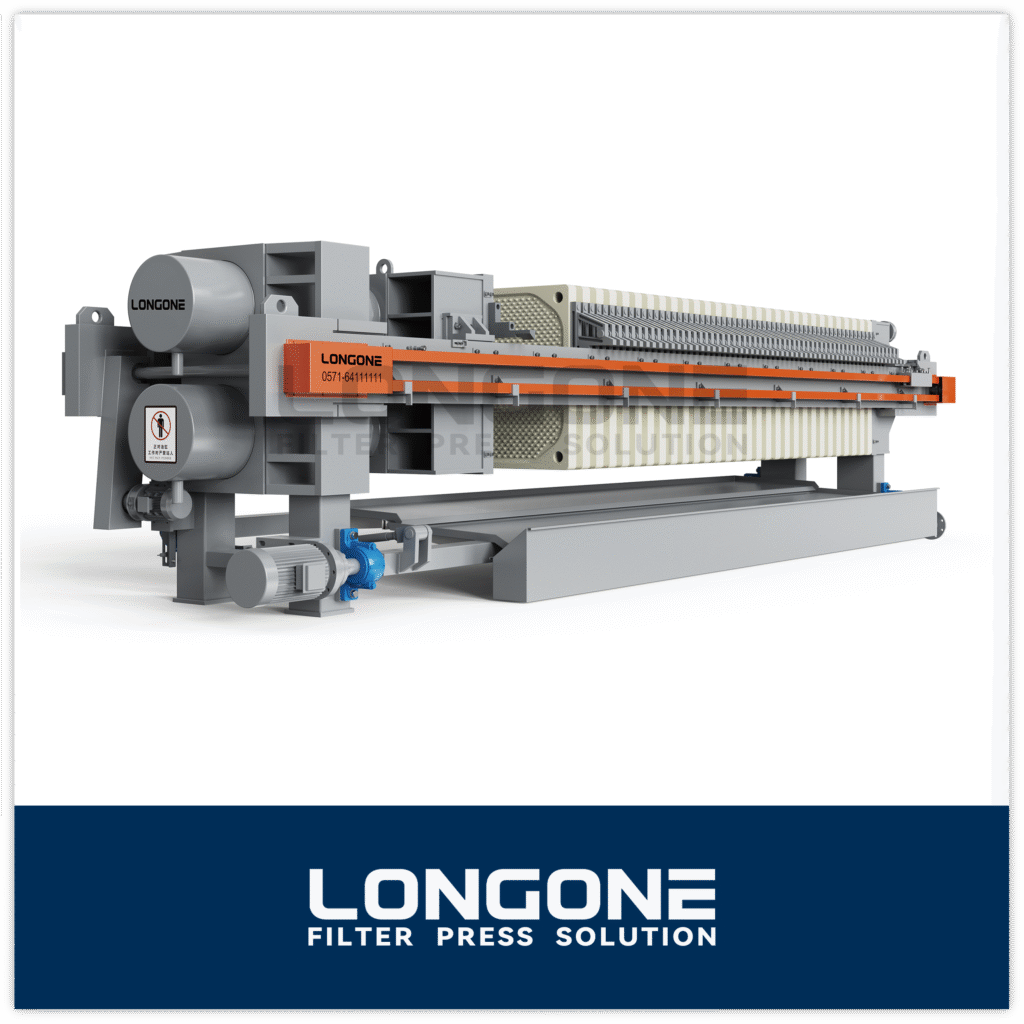

In addition to belt conveyors, we also supply filter presses designed for seamless system integration and efficient dewatering solutions.