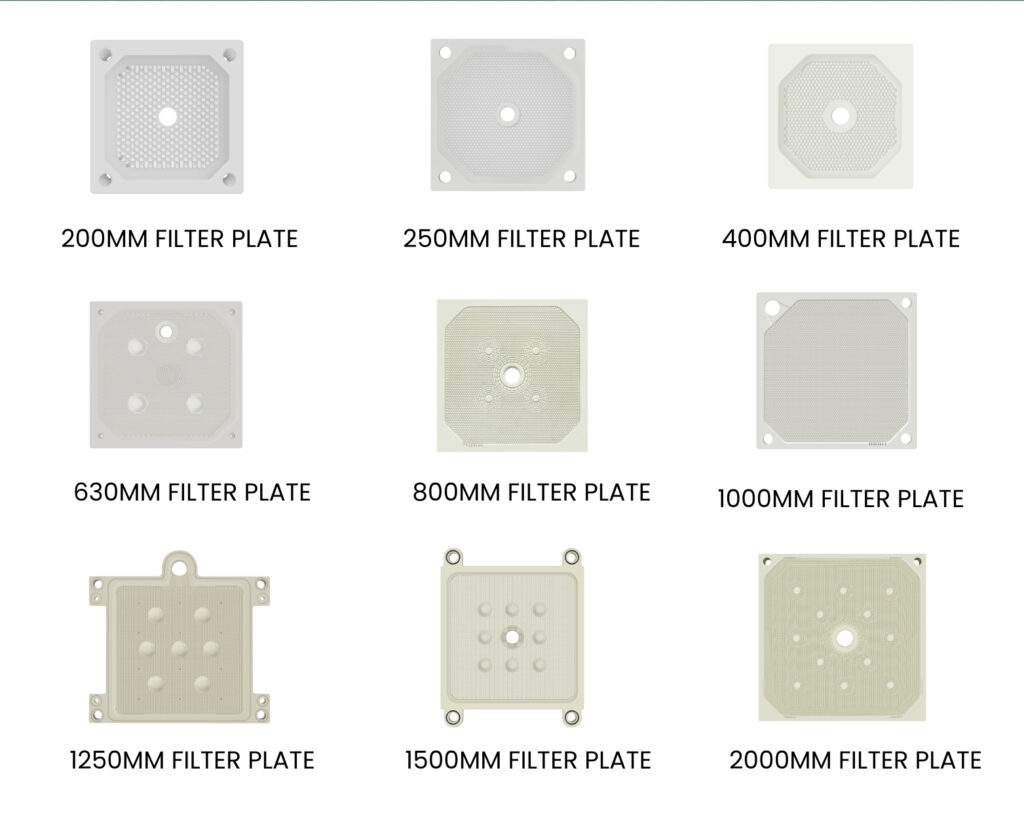

Filter Press Plates Manufacturer

LONGONE is a top Chinese company that makes high-quality filter press plates for a wide range of applications that separate liquids from solids. Our plates are stronger, more stable, and better at filtering because they are made with advanced engineering, precision molding technology, and long-lasting polypropylene materials. We have chamber plates, membrane plates, CGR plates, and plate-and-frame designs that work with most filter press brands around the world. LONGONE has reliable products and expert technical support to meet your operational needs, whether you need standard sizes or fully customized solutions for mining, chemical processing, wastewater treatment, or metallurgy.

Types of Filter Press plate

We sell chamber plates, membrane plates, CGR plates, and plate-and-frame plates. A wide range of industrial filtration systems can use them, and they all function well and last a long time.

Filter Plates manufacturer

Chamber filter plates are the most common type of plate used for standard filtration because they work well and are very stable. LONGONE makes chamber plates out of high-strength polypropylene that can be used in a wide range of industries and filtration situations.

Key Advantages:

– Strong design that can handle high filling and operating pressure

– Great sealing ability with the option of a CGR (gasketed) structure

–Works with systems that shift plates mechanically

– Little leaking and less need for maintenance

–Great for mining, chemicals, treating wastewater, and other industrial uses

Filter Plates manufacturer

Membrane filter plates are made for jobs that need faster filtration cycles and better dewatering. LONGONE makes high-quality polypropylene membrane plates that work better for squeezing and can easily adapt to different slurry conditions.

Key Advantages:

– Secondary membrane squeezing helps get rid of more moisture.

– Shorter filtration cycle to get more done

– Best for slurries with a lot of solids or that can be compressed easily

– Better washing and cleaner filtrate

– Good for tough industries like mining, metallurgy, chemicals, and sludge treatment

Filter Plates manufacturer

LONGONE makes filter press plates that can be fully customized to meet the specific needs of different industries. Our engineers make sure that the plate design, materials, feed positions, sealing structures, and plate thickness are all perfect for the best filtration performance and long-term reliability.

Choices for Customization:

– Types of feed: center, corner, or top feed

– Structures: non-gasketed, CGR, chamber, membrane, or plate-and-frame

– Materials: reinforced PP and special blends of polymers

– Custom thickness, filtration area, and pressure ratings for cakes

– Special designs for use in high-temperature, corrosive, or abrasive situations

Filter Plates manufacturer

| Plate Size | Press Capacity |

|---|---|

| 470mm | 1–5 cu.ft. |

| 630mm | 2–10 cu.ft. |

| 800mm | 5–30 cu.ft. |

| 1000mm | 40–150 cu.ft. |

| 15000mm | 100–300 cu.ft. |

LONGONE's Service

Professional Engineering Team

Provides operational analysis and filter plate selection

Rapid Response

Offers quotations, technical consultation, and after-sales support

Multi-Industry Experience

Covers hydrometallurgy, chemical industry, electroplating, mining, environmental protection, etc.

Global Coverage

Suitable for major international brand filter presses

We use advanced molding technology and strict dimensional control to make our plates. This makes them stronger, more stable, and able to last longer in tough industrial filtration conditions.

We make chamber, membrane, CGR, and plate-and-frame designs out of high-quality polypropylene that is very resistant to chemicals, seals well, and works with most filter press brands around the world.

LONGONE delivers tailored filtration solutions based on slurry characteristics, pressure requirements, cycle time, and industry needs, supported by a technical team offering full consultation and after-sales service.

Common Issues for Filter Press Plates

Because filter press plates work under high pressure and run all the time, they can wear out over time. Regular checks and timely replacements help keep the filtration system running smoothly and prevent unexpected downtime.

Some common problems are:

1. Plate changes shape because of too much pressure over time

2. Cracks that happen because of wear and tear or impact

3. Leakage due to worn gaskets or bad sealing

4. Less effective filtration because of surface wear

5. Having extra plates on hand makes sure that operations run smoothly and that production losses are kept to a minimum, especially in important industrial processes.

Operating Conditions to Consider When Selecting Filter Plates

You need to look at the actual working conditions and the properties of the material to choose the right filter press plate. LONGONE suggests plates based on the needs of your particular process.

Important Things to Think About:

1. Type of slurry, amount of solids, and properties of the particles

2. Needed cake dryness, washing speed, and filtering speed

3. Pressure for operation, pressure for squeezing, and frequency of cycles

4. The material’s chemical compatibility and level of wear

5. Desired thickness of the cake and depth of the filtration chamber

Choosing the right plate improves dewatering performance, extends the life of the system, and keeps it running smoothly.

HQ Address

No.111 Fengxiang Road, Tonglu Economic Development Zone, Hangzhou, Zhejiang Province

Email Address

info@longonefiltra.com