We are a professional lab filter press manufacturer that focuses on making laboratory-scale filtration equipment that works as well as industrial-grade equipment but is smaller and easier to use. Our lab filter presses are made for research institutions, pilot plants, universities, and small-batch production settings that need solid-liquid separation that is accurate, repeatable, and quick. We offer solutions that help with process development, quality control, and material testing in many industries. Our products are customizable, built to last, and have high filtration accuracy.

- Comprehensive Manufacturing Capability: Full OEM/ODM service covering sintering, machining, welding, polishing, painting, and assembly.

- High Filtration Precision: Allows for precise lab analysis by supporting micro-filtration, cake washing, and high-pressure dewatering.

- Customizable Designs: You can change the filter plate material, the number of plates, the structure, the feeding method, and the extra systems to fit your project.

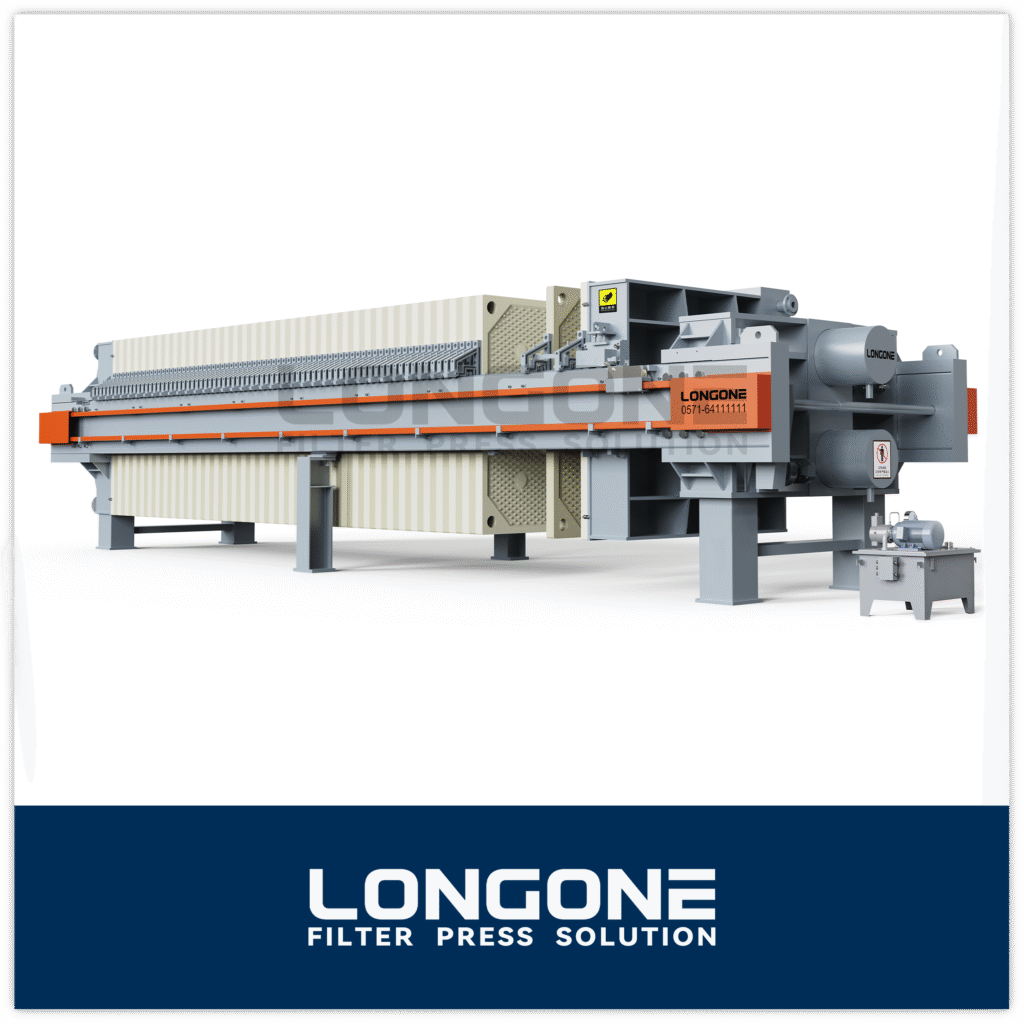

Filter Press manufacturer

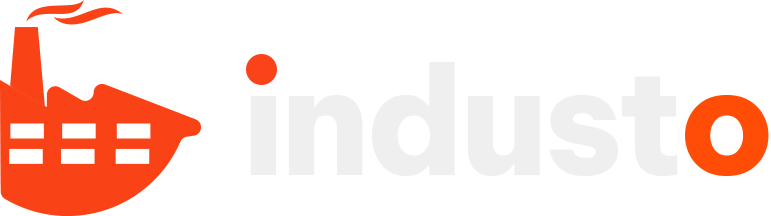

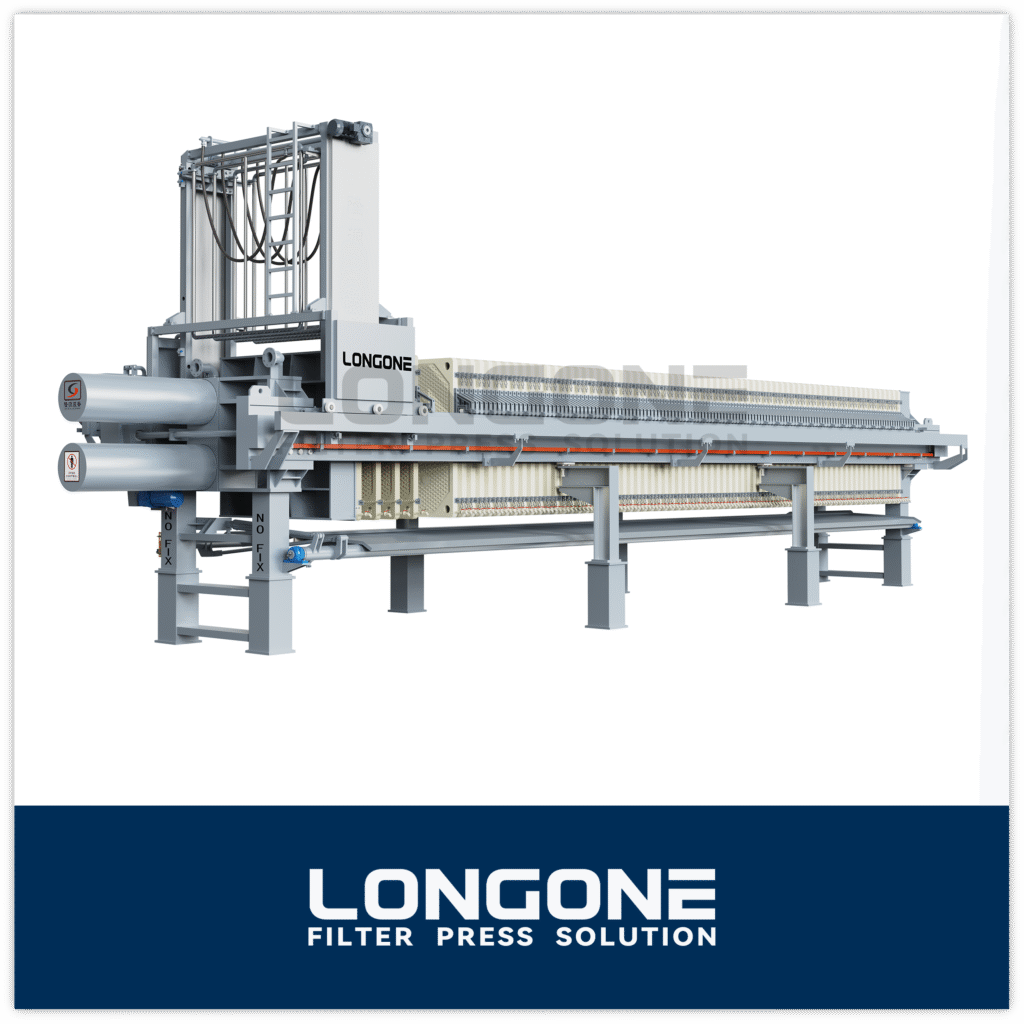

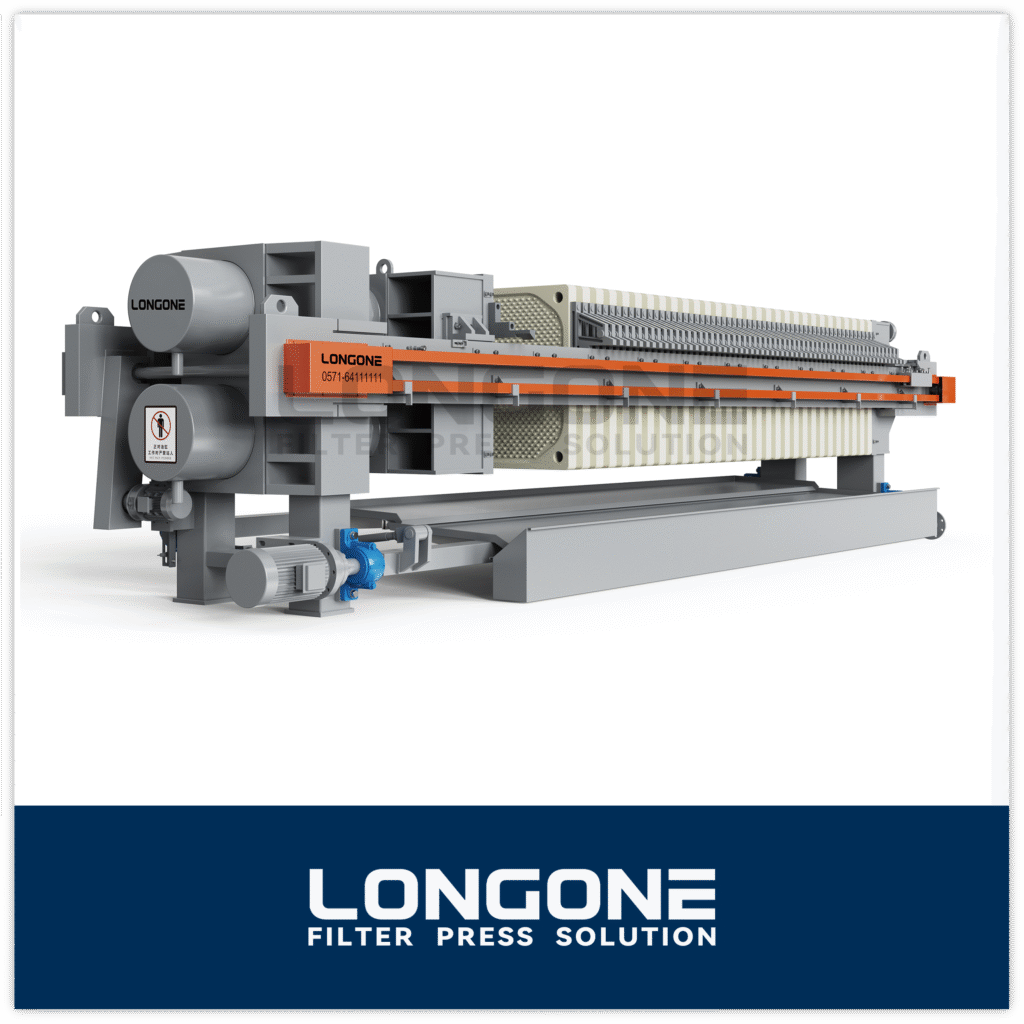

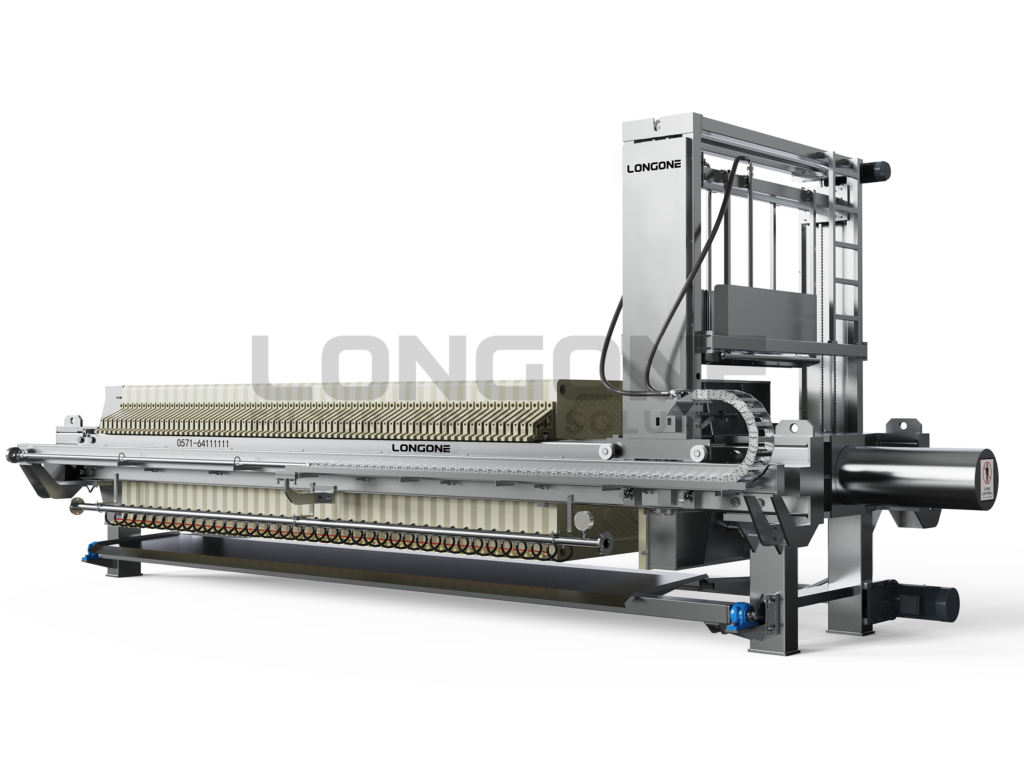

Product Name: stainless steel filter press

Brand Name: LONGONE

Material: High-grade stainless steel (SS304, SS316, SS316L)

Customization: Supported

Filter Press Price: Negotiable

Minimum Order Quantity: 1 unit

Application Areas: Pharmaceutical Preparation, Plasma Separation, Chemical Filtration, Food and Beverage Industry, Beer and Wine Production

Filtration precision: 200 mesh, 300 mesh coarse filter cloth to 0.22μm, 0.45μm fine filter paper, filter membrane.

Key Advantages

Our stainless steel filter press is designed to provide better filtration, a longer service life, and a steady level of product purity. It is made with high-tech materials and precise craftsmanship to make sure that solid-liquid separation works well in a wide range of industries. This equipment works steadily, hygienically, and reliably to meet the high standards of production, whether it is used for coarse filtration or fine clarification.

Key Advantages:

– High-Purity Filtration

– Durable Construction

– Flexible Configuration

– Leak-Free Operation

Our stainless steel filter press provides high-purity filtration, long-lasting durability, and dependable performance in tough industrial settings, making sure that the output is clean and the operation is efficient.

1. Prevents contamination with full stainless-steel contact parts

2.Supports fine filtration down to 0.22μm

3.Ensures hygienic processing for sensitive industries

4.Ideal for food, beverage, and pharmaceutical applications

1.Corrosion-resistant SS304/SS316/SS316L construction

2.Extended service life under high pressure and temperature

3.Stable performance in harsh chemical environments

4.Lower maintenance requirements

1.Fast filtration cycles with optimized flow paths

2.Compatible with manual, semi-automatic, or fully automated systems

3.Minimal product loss with optional CGR gasketed plates

4.Flexible configurations tailored to various filtration processes

filter press Solution

Felxible Payment

We accept T/T, L/C at straight, PayPal, and more methods.

Quality Assurance

Quality control at every stage of the manufacturing process.

Effective Logistic

Safe and reliable logistics services covers more than 30 countries.

Customize Service

We can tailor a filter press to your specific needs.

How the Stainless Steel Filter Press Works

The stainless steel filter press works by using a closed pressure-filtration process that is meant to separate solids and liquids quickly. The slurry is pumped into chambers made by stainless steel filter plates while the machine is running. The liquid goes through the chosen filter cloth or membrane when there is pressure, and solid particles build up inside the chamber to make a compact filter cake. After the filtration is done, the plates open and the filter cake comes out. The system can do coarse filtration, fine filtration, clarification, or sterilization by using different types of filters and plates. This lets it meet the needs of many different industries.

Technical parameters

| Specs | Details |

|---|---|

| Filtration Area | 0.16 m² to 1600m² |

| Feeding Type | Top feeding, center feeding, corner feeding |

| Filter Pressure | 0.6 MPa to 6.0 MPa |

| Filtration Temperature | -40℃ to 120℃ |

| Hydraulic System | Manual, semi-automatic, or fully automatic options |

Customized Solutions to Fit Your Filtration Needs

You can fully customize our stainless steel filter press to fit your process, product features, and production environment. We offer custom configurations to help you get the best performance and reliability, whether your main concerns are hygiene, capacity, automation, or filtration accuracy.

- Material Selection:Choose SS304, SS316, or SS316L based on corrosion resistance and sanitation requirements.

- Filter Plate Types:Membrane, recessed chamber, plate & frame, or gasketed (CGR) plates for different filtration outcomes.

- Automation Levels:Manual, semi-automatic, or fully automatic hydraulic systems for improved efficiency.

- Process Adaptation:Top, center, or corner feed; adjustable filtration area, pressure, and temperature to suit your application.

Shipping and Delivery

We ship all over the world and make sure that your package is safe and that the logistics are well-coordinated. We make sure that our filter presses and accessories get to your facility on time and with full tracking, export paperwork, and protection.

Related products

To meet different application needs, we also offer a full range of filtration solutions, such as the Chamber Filter Press, Frame And Plate Filter Press , Membrane Filter Press, and Sludge Filter Press.

HQ Address

No.111 Fengxiang Road, Tonglu Economic Development Zone, Hangzhou, Zhejiang Province

Email Address

info@longonefiltra.com