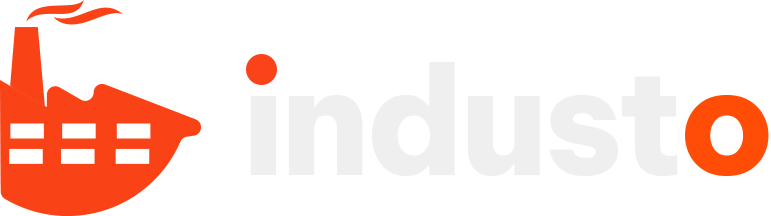

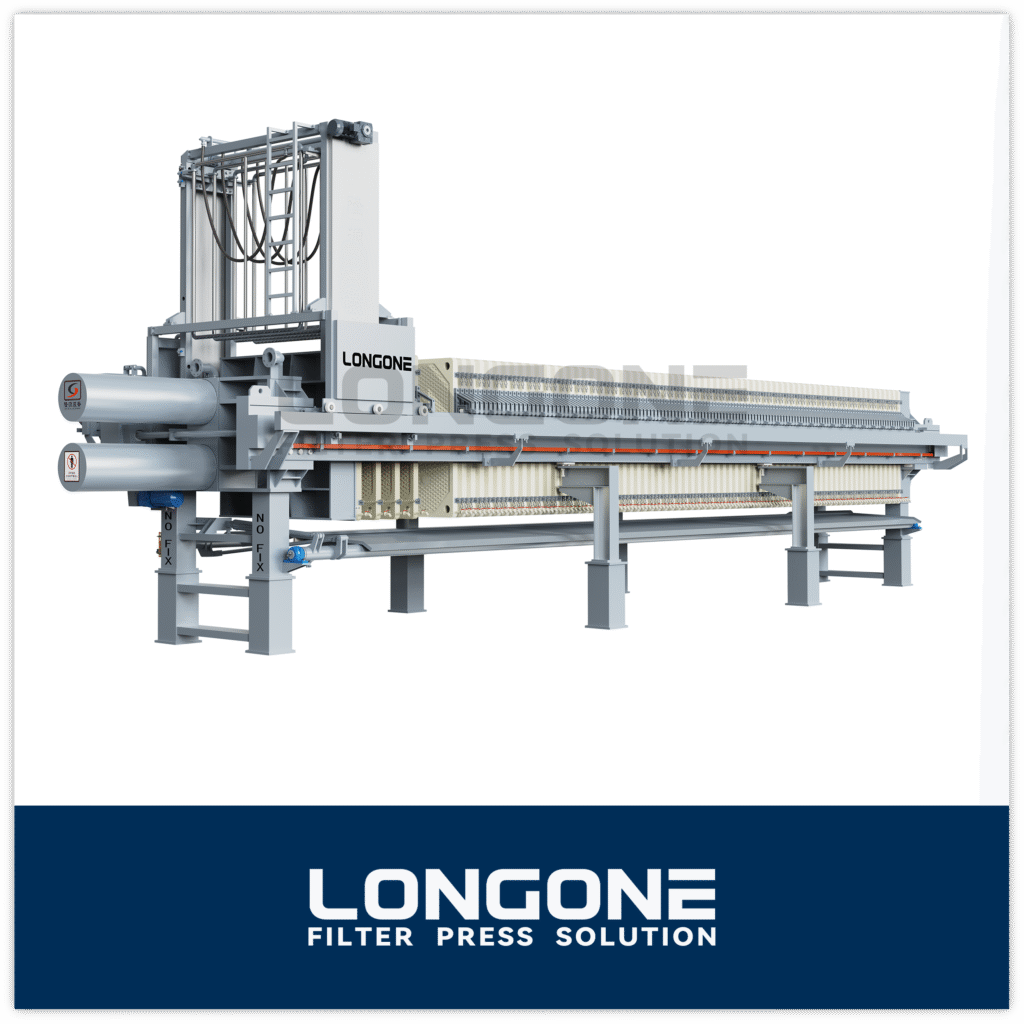

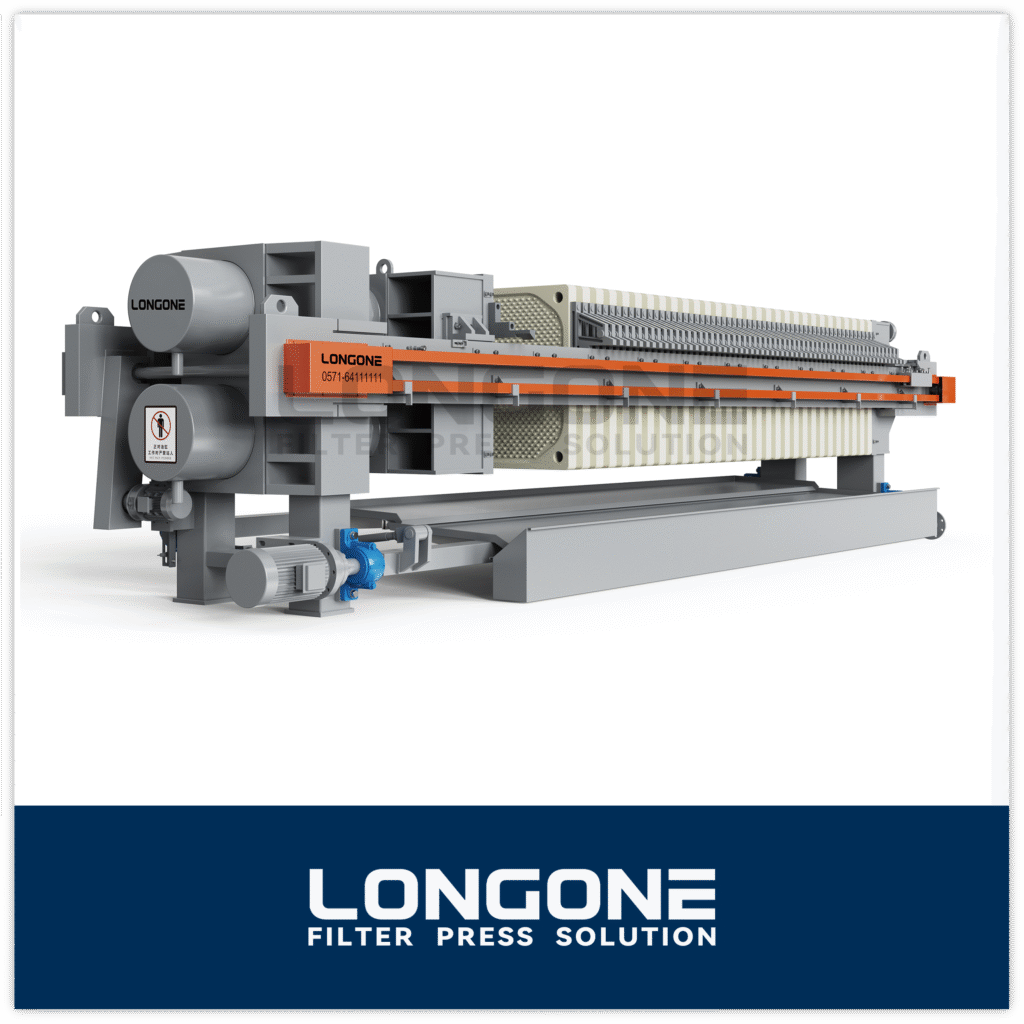

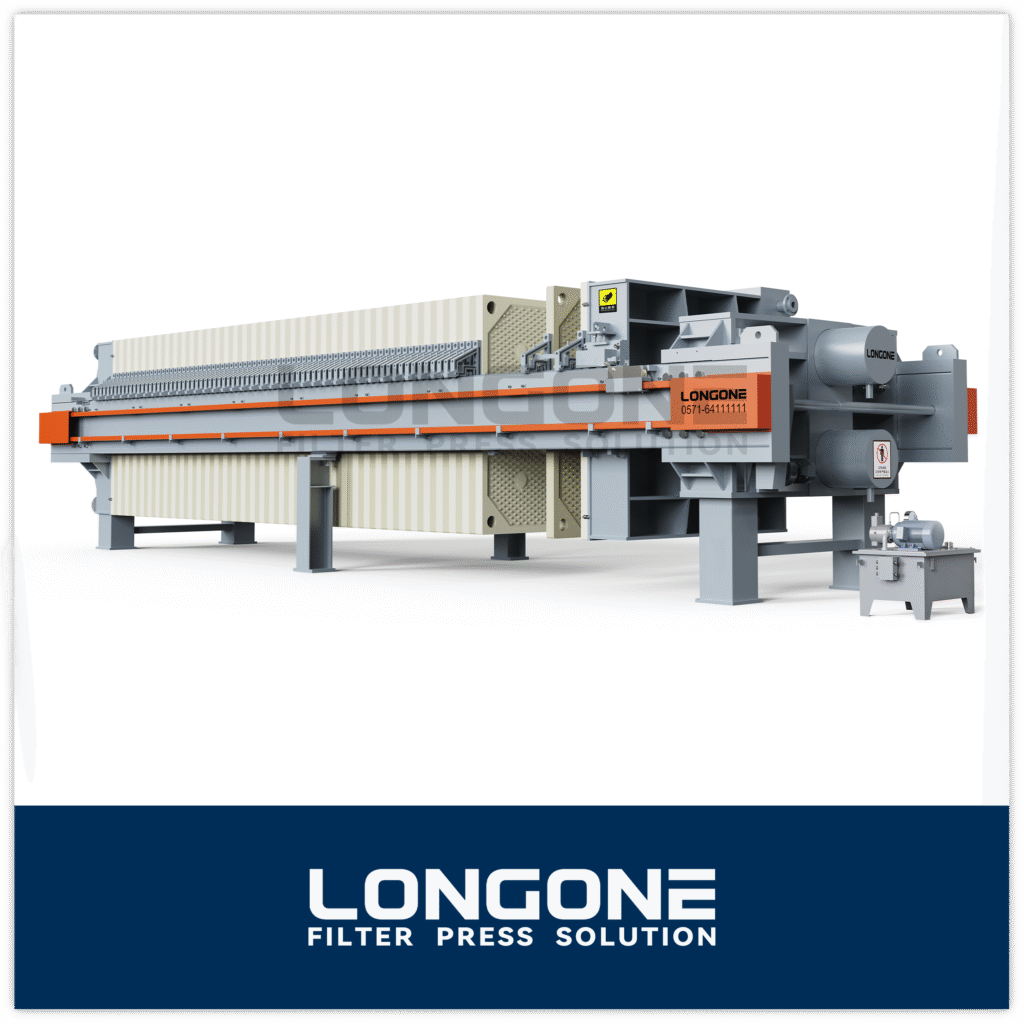

LONGONE is the leading manufacturer of sludge filter press machines in China. We offer reliable and affordable ways to remove water from municipal and industrial wastewater. Our sludge filter presses are made with heavy-duty steel frames, high-performance polypropylene plates, and cutting-edge hydraulic systems to make sure they work well and last a long time. We have a wide range of sizes, filtration capacities, and custom configurations to fit the different types of sludge and processing needs. LONGONE has the right solution for your plant, whether you need to separate solids and liquids quickly, cut down on sludge volume, or run your plant automatically.

- Customizable Designs: Multiple plate sizes, filter cloth options, and automation upgrades.

- High Dewatering Efficiency: Get more solid content with performance that is always the same and can be repeated.

- Full Support: All the spare parts, accessories, and professional technical help you need.

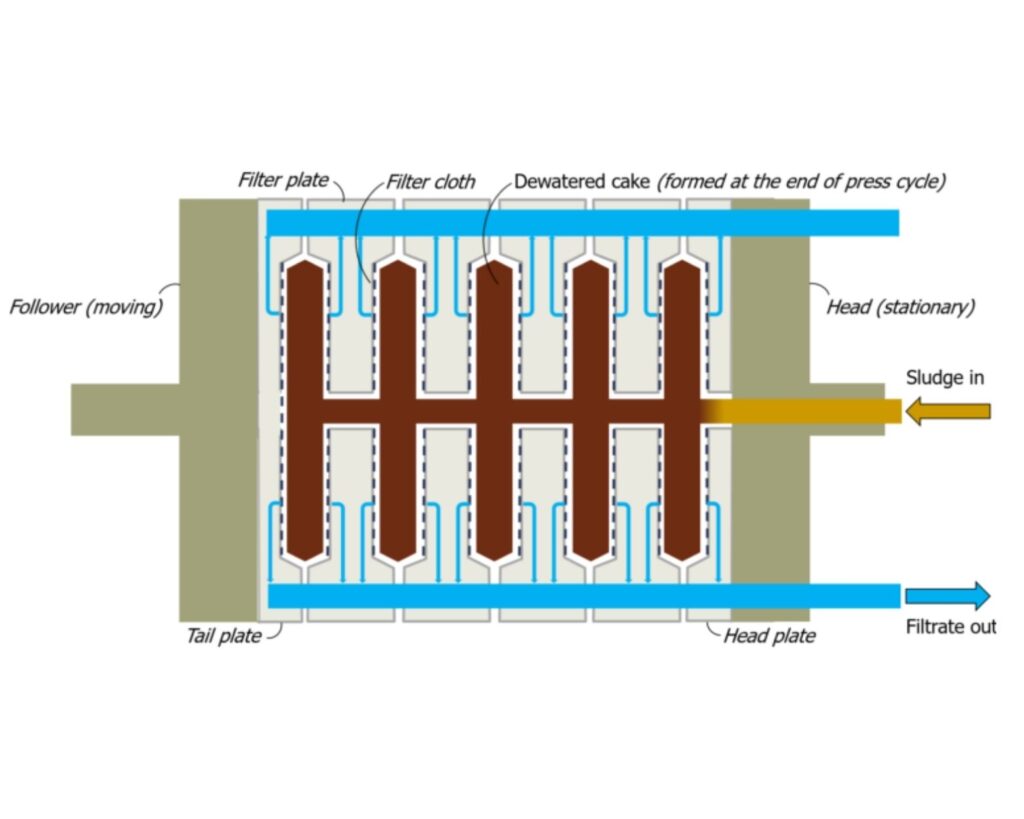

A sludge filter press is a machine that separates solid and liquid waste. It is used to remove water from sludge that comes from treating municipal and industrial wastewater. It pushes water through filter cloths using mechanical or hydraulic pressure while keeping solids inside the filter chambers. This creates compact filter cakes that are easy to handle.

The LONGONE sludge filter press is very good at removing water, works well all the time, and costs very little to run. It has a lot of solid content, filters well, and can be set up in different ways, so it works with a lot of different types of sludge and helps cut down on the amount of waste that needs to be thrown away or recycled.

Sludge Filter Press manufacturer

Product Name: Sludge Dewatering Filter Press

Brand Name: LONGONE

Type: Semi-automatic, Fully Automatic, Fully Automatic

Customization: Supported

Filter Press Price: Negotiable

Minimum Order Quantity: 1 unit

Processing capacity: 4,500 – 90,000 gallons/day

Cake solids content: 30–35% (standard)

High-end equipment can achieve: up to 80% solids content (depending on sludge properties)

China Sludge Filter Press

| Plate Size | Press Capacity |

|---|---|

| 470mm | 1–5 cu.ft. |

| 630mm | 2–10 cu.ft. |

| 800mm | 5–30 cu.ft. |

| 1000mm | 40–150 cu.ft. |

| 15000mm | 100–300 cu.ft. |

Fast and reliable filter press supply

Shipping Coverage: Global.

Packaging: Container.

Lead Time: 15-30 days. May vary depending on your order requirements.

Payment Options: T/T, LC, OA.

Shipping Methods: CIF. FOB, CFR, and more.

Delivery Time: 30-45 days. Specific ETA depending on your location and shipping methods.

Customization supported

LONGONE makes sludge filter presses that can be fully customized to fit different types of sludge, processing needs, and installation conditions. Every system can be designed to meet your needs, from the size of the plate to the level of automation, to make sure that it works as well as possible and lasts for a long time.

- Plate Sizes & Chamber Capacity: Multiple sizes from 470–1500 mm with optional expansion.

- Filter Plate & Cloth Configurations: Different materials, patterns, and pore sizes.

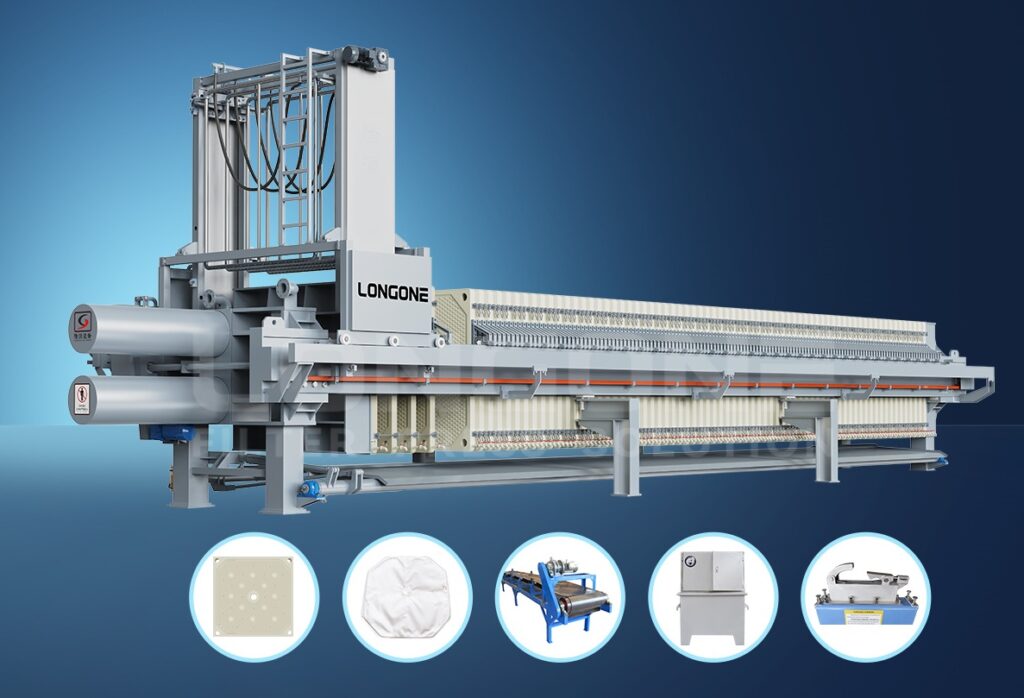

- Automation Upgrades: Automatic plate shifter, cloth washing system, pump control, and PLC operation.

- Structural Enhancements: Elevated stands, platforms, covers, and tailored layouts.

Advantages of Sludge Filter Press

High Solid Content

Produces dense filter cakes with significantly reduced moisture levels.

Efficient Dewatering

Strong filtration pressure ensures fast and consistent sludge dewatering.

Low Operating Cost

Minimal energy consumption and limited operator intervention required.

Stable Performance

Reliable structure provides long-term, repeatable filtration results.

Wide Applicability

Suitable for various municipal, industrial, and mineral sludge types.

Customizable Configuration

Multiple plate sizes, cloth materials, and automation options available.

Easy Maintenance

Simple filter cloth replacement and convenient system cleaning.

Environmentally Friendly

Reduces sludge volume and supports sustainable waste management.

Our dedicated R&D team is always working on new filtration technologies that make dewatering more efficient, make equipment last longer, and come up with new ways to treat sludge that meet the needs of different industries.

We offer expert technical advice, help with choosing the right model, help with installation, and responsive after-sale service to make sure everything runs smoothly, increases productivity, and keeps customers happy for a long time.

Every sludge filter press undergoes rigorous material selection, precision manufacturing, and multi-stage testing to guarantee stable performance, long service life, and consistent filtration results in demanding environments.

How a Sludge Filter Press Works

The sludge filter press uses pressure to separate solids and liquids.

- Feeding Sludge: The sludge pump sends sludge to the spaces between the filter plates.

- Filtration Stage: Water is pushed through the micropores in the filter cloth at a pressure of 7 to 20 bar.

- Cake Formation: Solids get stuck in the filter chambers, which slowly turns them into a filter cake with a lot of solids.

- Filtrate Discharge: The plant’s wastewater treatment system gets the filtrate back.

- Cake Discharge: The dry solids fall on their own or with help after the filter plates open.

Sludge Filter Press Selection Guide

Choosing the right sludge filter press makes sure that it works well and lasts for a long time. Think about these important things:

Sludge Type: Different sludges require specific filter cloth materials and press types.

Processing Capacity: Select a model based on daily or hourly sludge production.

Filter Cake Moisture: Ensure the press can achieve the desired solid content for disposal or recycling.

Automation Level: Choose manual, semi-automatic, or fully automated systems based on labor and budget.

Installation Space: Consider the available site area for proper press dimensions and layout.

Proper selection maximizes performance, reduces operating costs, and extends equipment lifespan.

Related products

To meet different application needs, we also offer a full range of filtration solutions, such as the Chamber Filter Press, Frame And Plate Filter Press , Membrane Filter Press, Stainless Steel Filter Press, and Lab Filter Press.

HQ Address

No.111 Fengxiang Road, Tonglu Economic Development Zone, Hangzhou, Zhejiang Province

Email Address

info@longonefiltra.com