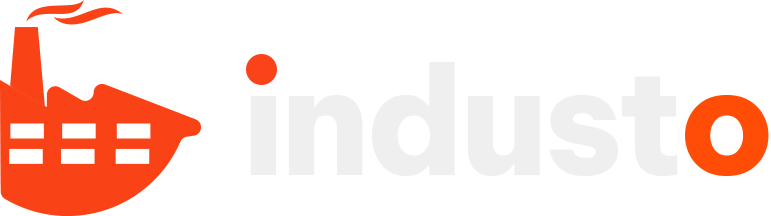

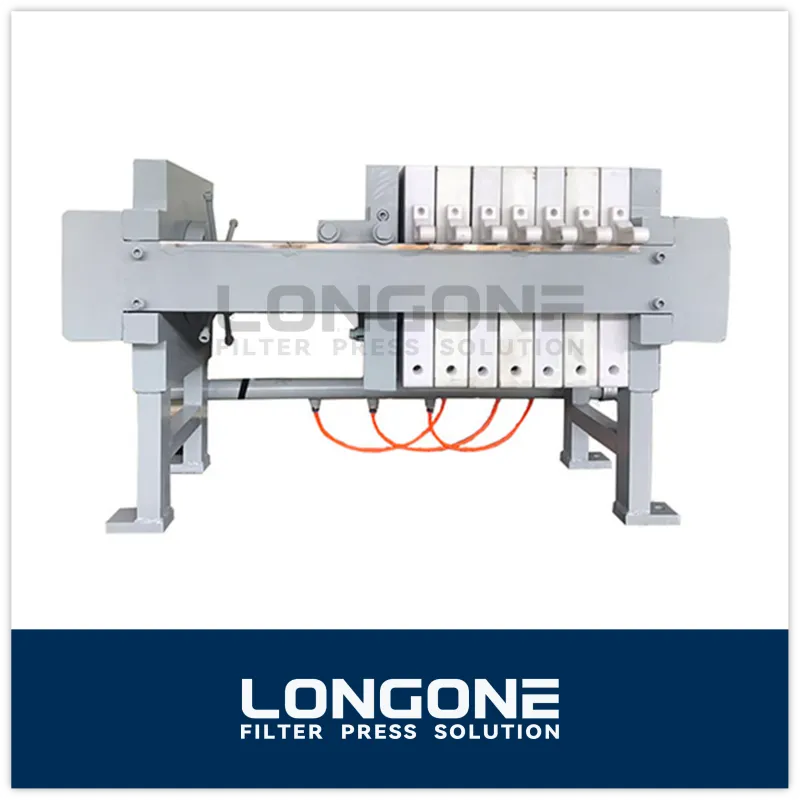

Longone is a top manufacturer of China frame and plate filter presses. We provide reliable and effective solid-liquid separation solutions for a wide range of industries, including chemicals, mining, wastewater treatment, and food processing. Our frame and plate filter presses have a simple design, are easy to use, and work reliably, making them great for both regular and heavy-duty jobs. We offer complete filtration solutions, including filter plates, filter cloths, pumps, conveyors, and accessories, to ensure excellent filtration efficiency and long-lasting durability. Our engineers have a lot of experience and can design systems that are just right for your needs.

- Custom-Engineered Solutions

- High-Quality Filtration Components

- Professional Technical Support

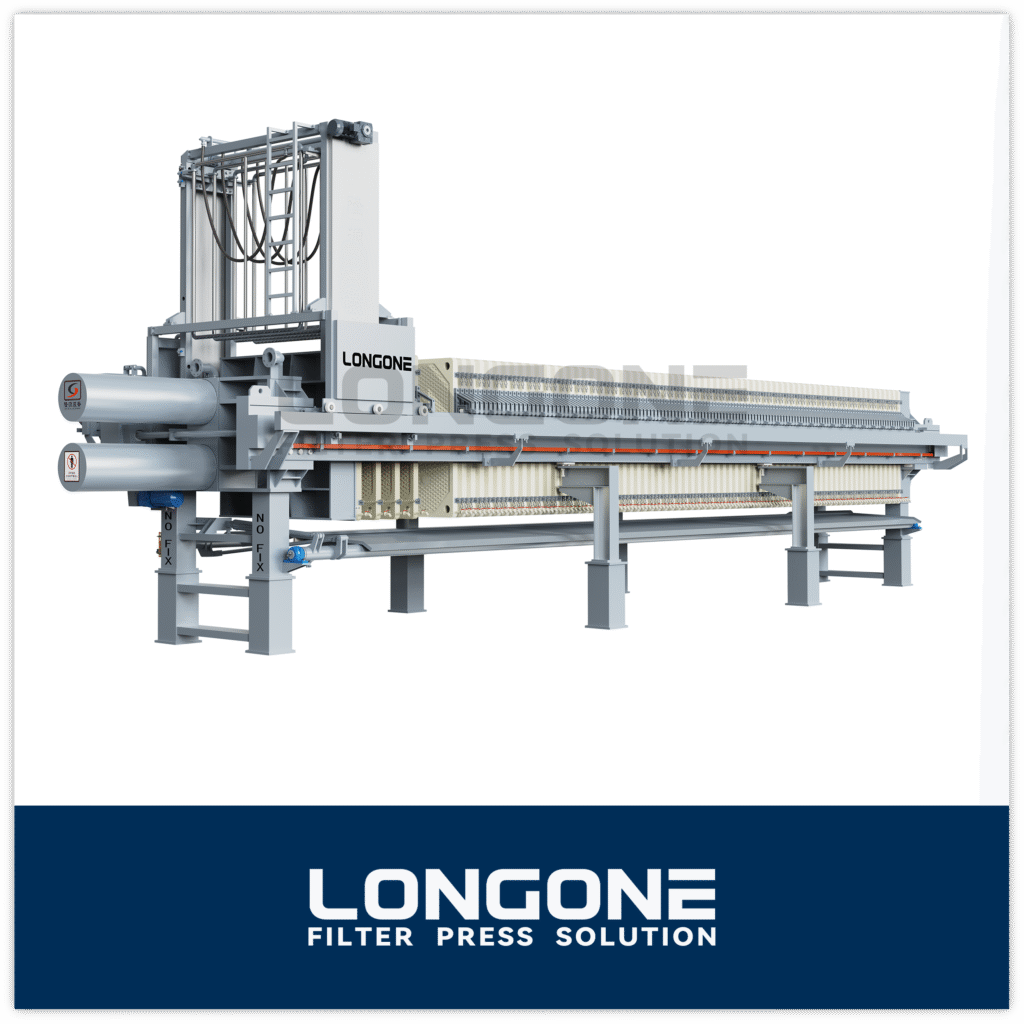

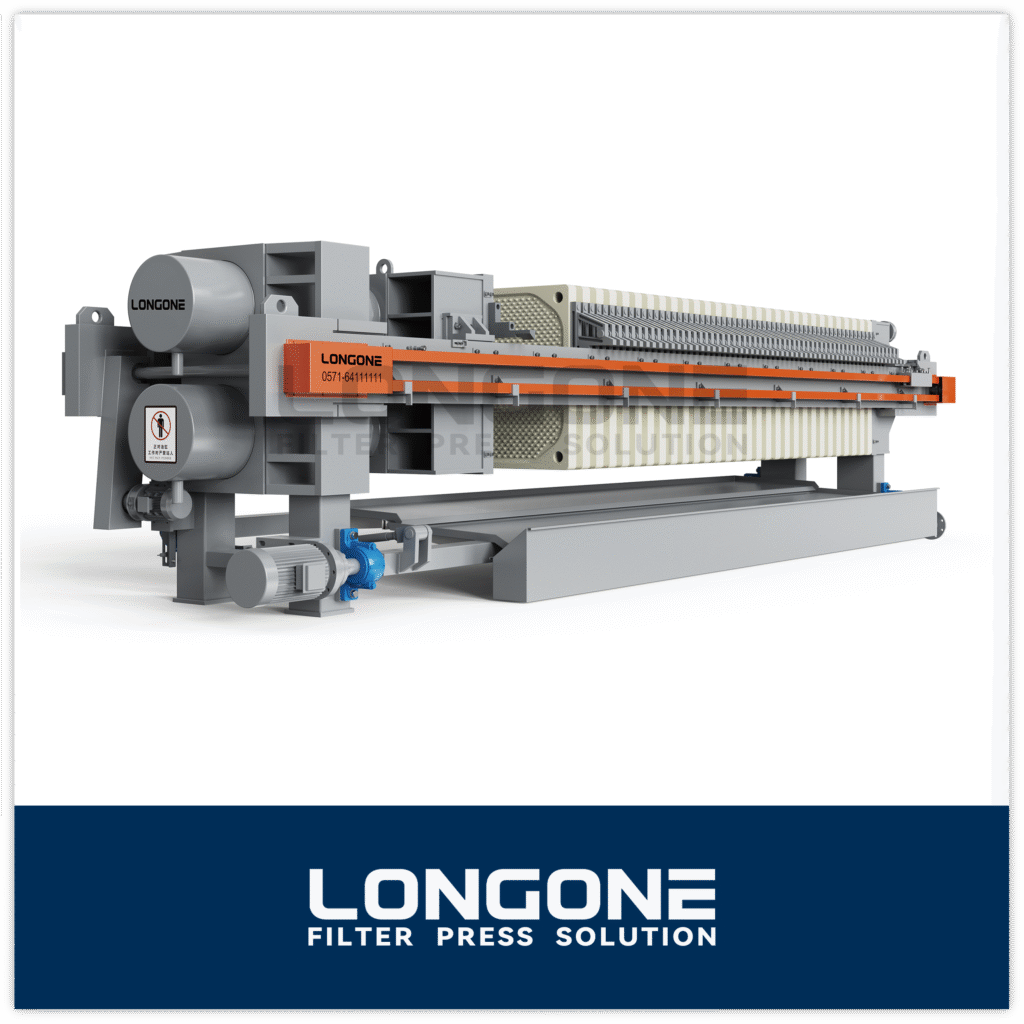

Our plate and frame filter presses have plates that last a long time, a precise chamber design, and a way to make cakes that works well. They work well for standard filtration tasks and give consistent results across a wide range of industrial uses.

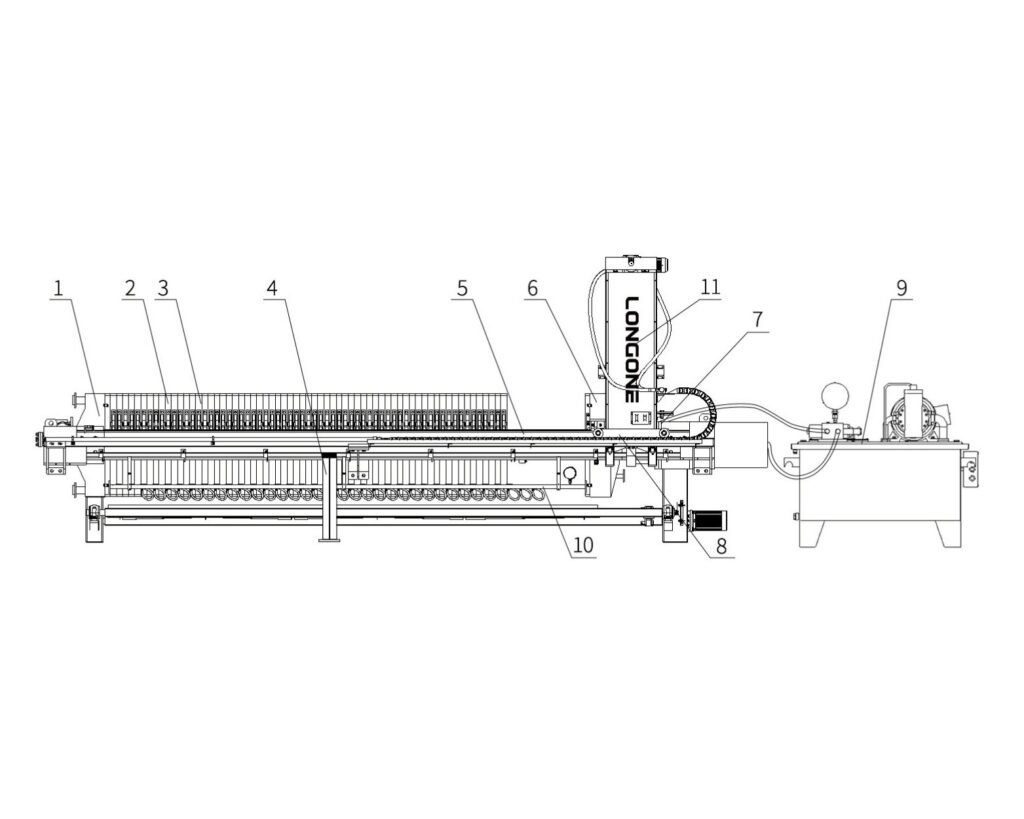

Structure Composition

A plate and frame filter press consists of key components working together to achieve effective solid-liquid separation:

- Filter Plates & Frames: Alternately arranged to form filtration chambers.

- Filter Cloth: Fixed on plates to retain solids and allow filtrate to pass.

- Thrust Plate & Pressure Plate: Clamp the plate pack tightly under hydraulic force.

- Hydraulic System: Provides the necessary pressure for sealing and filtration.

- Beams & Support Structure: Ensure stability during operation.

- Filtrate Collection System: Directs the clarified liquid to discharge outlets.

Together, these elements create a stable, sealed environment for efficient batch filtration.

- Feeding: A feed pump pushes slurry into the inlet, where it slowly fills alternating plate-and-frame chambers.

- Filling: The plates compress under hydraulic force, which seals the chambers. The slurry is then directed towards the filter cloth, and the filtrate leaves through drainage channels.

- Filtration: When pressure is applied, liquid flows through the cloth, leaving solids behind as a compact filter cake on each plate.

- Washing: The wash liquid flushes the cake to get rid of soluble impurities and make the final cake better.

- Drying: Keeping up the pressure or using compressed air for a short time lowers the amount of moisture left in the cake.

- Cake discharge: the hydraulic plates separate, and cakes are taken out by hand or machine. The plates are cleaned and put back together for the next cycle.

Advantages & Limitations

Pros

1. High Filtration Efficiency: The filter has a large area and can remove a lot of water, which makes the filtrate clear and the filter cakes small.

2.Simple and strong design: Fewer moving parts mean fewer breakdowns and easier daily maintenance.

3.Wide Range of Uses: Works with chemicals, food and drink, wastewater treatment, mining, pharmaceuticals, and more.

4.Saving energy and being good for the environment: low energy use with effective solid recovery.

Limitations

1.Labour-intensive Operation: Needs to be unloaded and cleaned by hand, which means more work for the workers.

2.Variability in the process: The type of filter cloth, the composition of the slurry, and the operating parameters all have a big effect on the results of filtration.

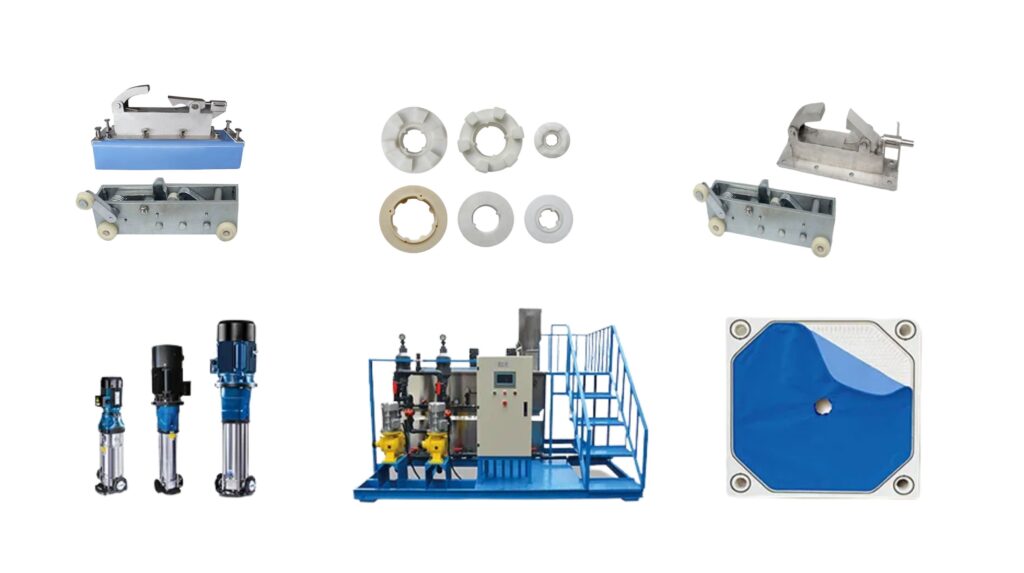

We sell frame and plate filter presses as well as other important tools and accessories that will help you get the most out of your filtration processes.

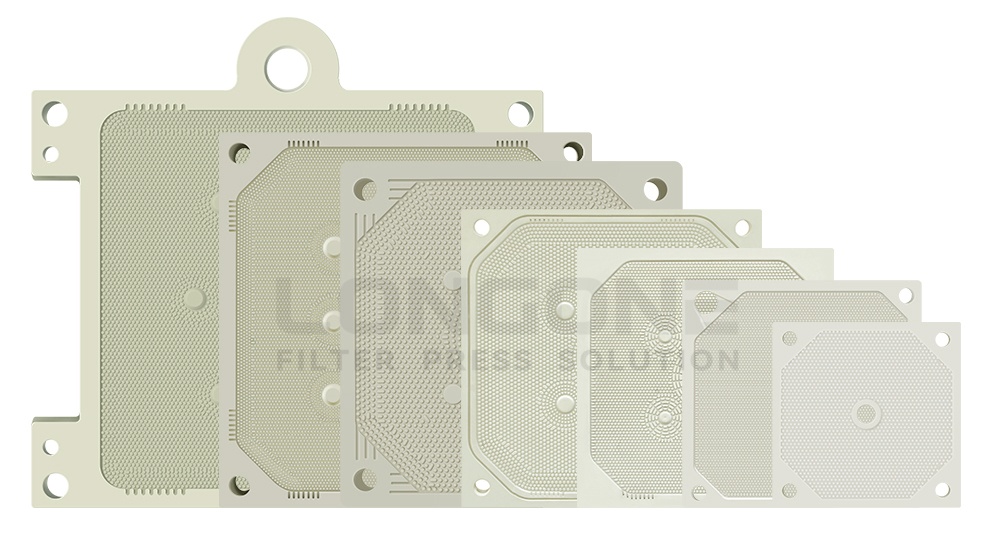

Our high-quality filter plates make sure that solid-liquid separation works reliably, lasts a long time, and works with many different filter press models. This makes filtration more efficient and makes the product clearer.

Our strong conveyors are made to safely and efficiently move filter cakes, which cuts down on the amount of work needed and makes handling them easier after filtration.

A full set of filter press accessories, such as cloths, seals, and hydraulic parts, makes sure that the equipment runs smoothly, is easy to maintain, and lasts longer.

Welcome to visit our factory

We sincerely welcome every customer to visit our factory for exchange and discussion. Please contact our staff via the button below, and we will arrange a visit for you as soon as possible.

Related products

To meet different application needs, we also offer a full range of filtration solutions, such as the Chamber Filter Press, Membrane Filter Press, Sludge Filter Press, Stainless Steel Filter Press, and Lab Filter Press.

HQ Address

No.111 Fengxiang Road, Tonglu Economic Development Zone, Hangzhou, Zhejiang Province

Email Address

info@longonefiltra.com