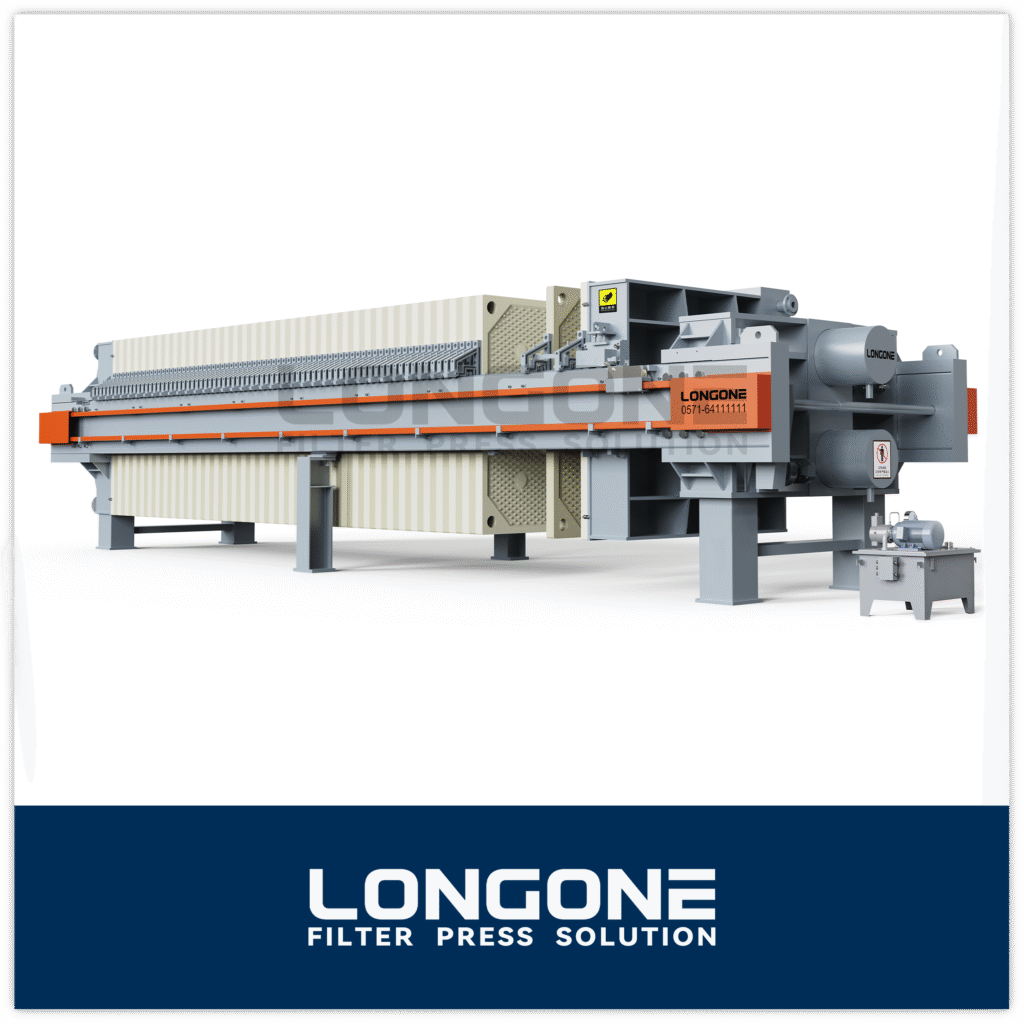

LONGONE is a leading membrane filter press supplier with more than 15 years of experience making, designing, and selling high-quality filtration equipment. We are a reliable Chinese supplier that specialises in providing fully customisable membrane filter press systems that meet international standards and can be used in many different industries, such as food and beverage, mining, wastewater treatment, chemicals, and pharmaceuticals. Our high-tech membrane filter presses are designed to remove as much water as possible, speed up the filtration process, and separate solids and liquids reliably. Our team offers continuous technical support to guarantee smooth installation, optimized performance, and maximum productivity for every project.

Higher Dehydration

Membrane squeezing delivers lower moisture content and drier filter cakes.

Shorter Filtration Cycles

Faster turnaround increases productivity and reduces operational downtime significantly.

Strong Pressure Resistance

Engineered to withstand high filtration pressure for stable, reliable performance.

Easy Maintenance Design

Replaceable membranes and accessible components simplify routine service work.

Enhanced Filtration Quality

Uniform cake structure delivers cleaner filtrate and more consistent solid-liquid separation results.

Corrosion-Resistant

Made with high-quality materials, ensuring a long service life in various corrosive environments.

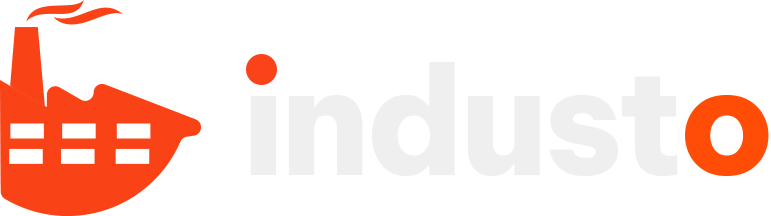

filter press manufacturer

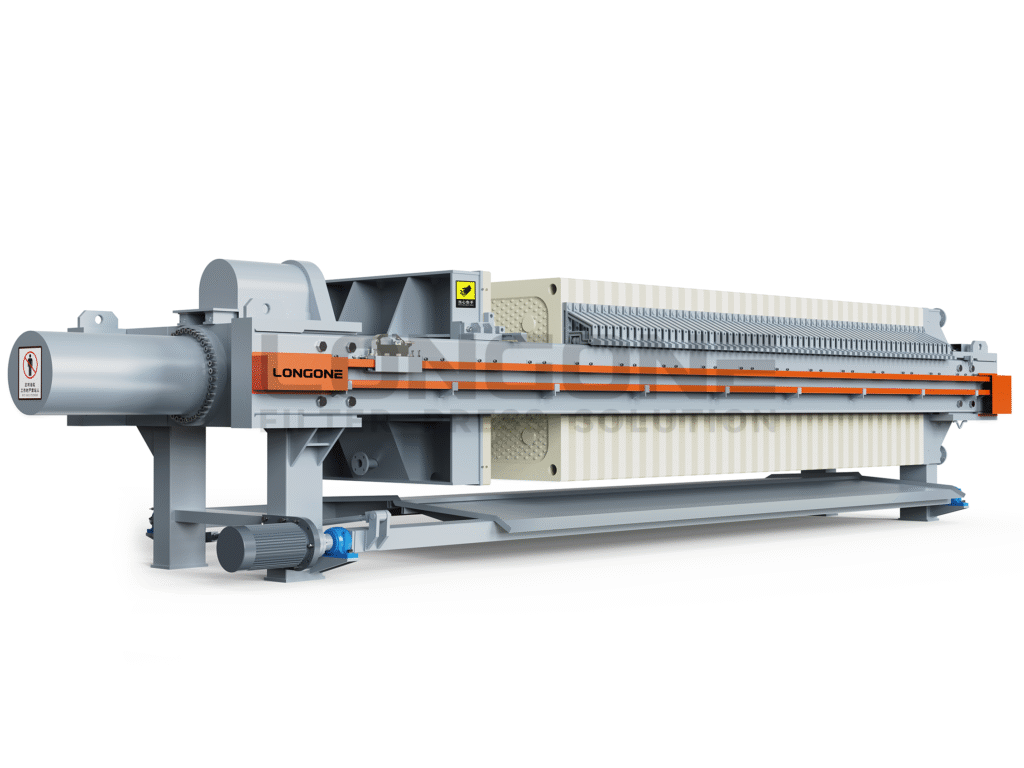

The LONGONE Membrane Filter Press is designed to separate solids and liquids quickly and easily, with better dehydration and shorter filtration cycles. It has advanced membrane plates and multiple feeding options, making it strong, stable, and able to work reliably in tough industrial settings.

- Product Name: Membrane Filter Press

- Brand Name: LONGONE

- Place of Origin: Hangzhou, China

- Filter Plates Type: Membrane type, rubber membrane type

- Feeding methods: Top feeding, center feeding, corner feeding

- Material: High-grade stainless steel (304, 316L), carbon steel Q345

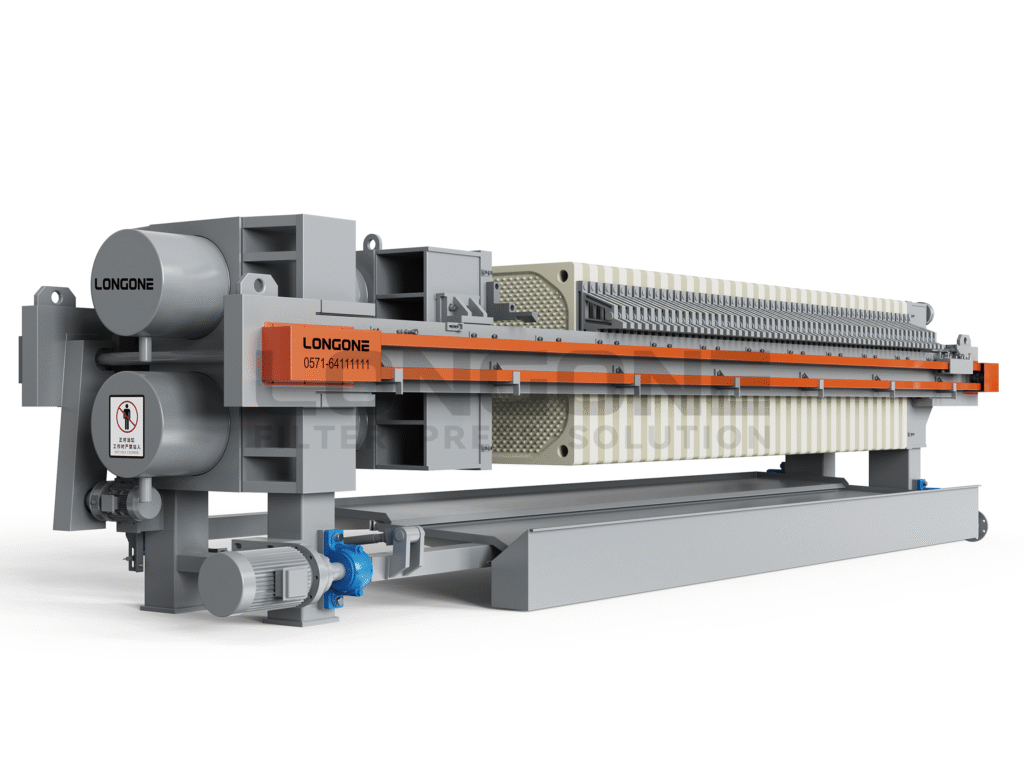

Membrane Filter Press specs

| Item | Specification |

|---|---|

| Filter Plates Size | 250mm×250mm to 2000mm×2500mm |

| Filtration Area | 0.16m² to 1600m² |

| Filter Pressure | 0.6 MPa to 6.0 MPa |

| Filtration Temperature | -40℃ to 120℃ |

| Filter press Hydraulic System | Manual, semi-automatic, or fully automatic options |

LONGONE makes membrane filter press systems that can be fully customised to meet the needs of your process, capacity, and industry. Our engineering team makes sure that our filters work at their best by:

- Custom plate materials and membrane types to fit the needs of the chemical, pharmaceutical, mining, or wastewater industries.

- You can choose to automate plate shifting, drip trays, washing cloths, and safety systems.

- Sizes and filtration areas that are made just for your production scale.

LONGONE makes sure that your membrane filter press runs more efficiently, has less moisture, and is reliable for a long time by customising it exactly to your needs.

Why choose us?

15+ years of experience

Our engineering team delivers proven membrane filter press solutions with stable performance, technical reliability, and industry-leading filtration results.

Good product quality

We use high-quality stainless steel, strong frames, and advanced membrane plates to make sure that our products last a long time, don't rust, and are strong.

Customized Solutions

We customise each system to fit your exact process and production needs, from the materials used for the plates to the ways they are fed and the options for automation.

Global After-Sales Support

LONGONE helps with installation, spare parts, troubleshooting, and long-term technical support to keep plants running smoothly and efficiently.

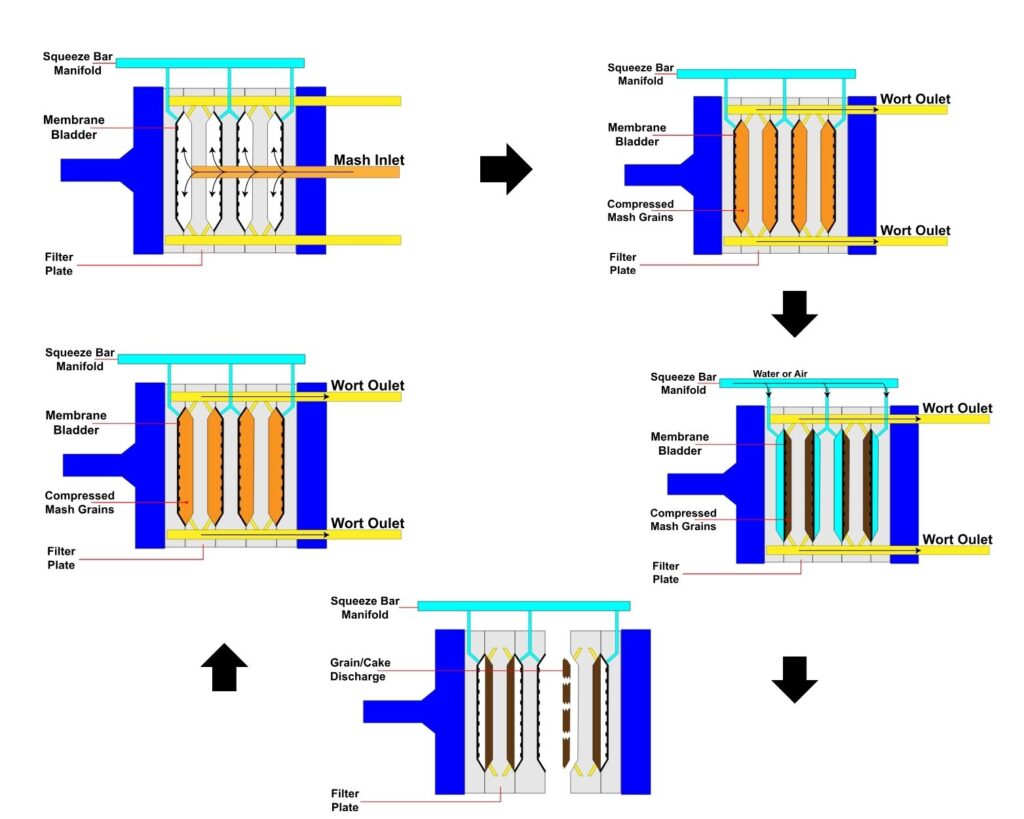

Membrane Squeezing Filtration Process

The membrane filter press works by squeezing and drying the material in a very effective way that maximises the separation of solids and liquids. The steps in the process are:

Pressure Sealing: The filter chamber is tightly sealed to keep the filtration pressure steady.

Feeding and Primary Filtration: The slurry enters the chamber and forms an initial filter cake through standard chamber filtration.

Filter Cake Washing: When needed, clean liquid flows through the cake to get rid of dirt.

Before Dewatering: The system stabilises before the membrane squeezing starts.

Membrane Squeezing and Final Dehydration: Flexible membranes expand to compress the cake, which lowers the moisture content and speeds up the cycle time.

Advantages of Membrane Filter Press

Compared to traditional chamber filter presses, the membrane filter press has many performance advantages, including higher efficiency and lower operating costs. Some of the main benefits are:

- Higher Dehydration Efficiency: Membrane squeezing significantly reduces cake moisture, achieving drier solids and improved disposal or recycling value.

- Shorter Filtration Cycles: Faster turnaround time increases production capacity and overall plant efficiency.

- Strong Pressure & Corrosion Resistance: Reinforced frames and premium materials ensure stable performance under high pressure and harsh chemical conditions.

- Easy Maintenance: Replaceable or welded membrane options allow quick maintenance without changing the entire filter plate.

- Enhanced Process Control: Adjustable membrane volumes and pressure settings support precise, reliable filtration for various industries.

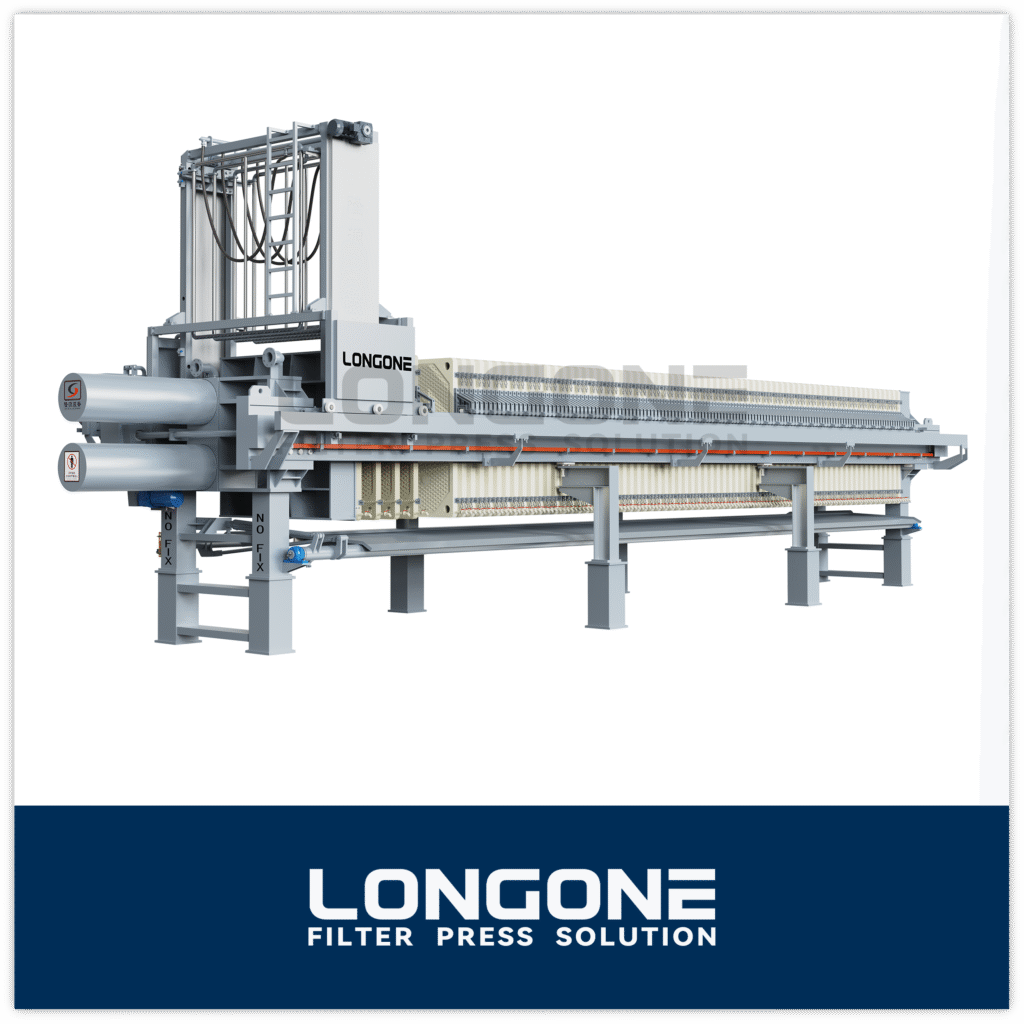

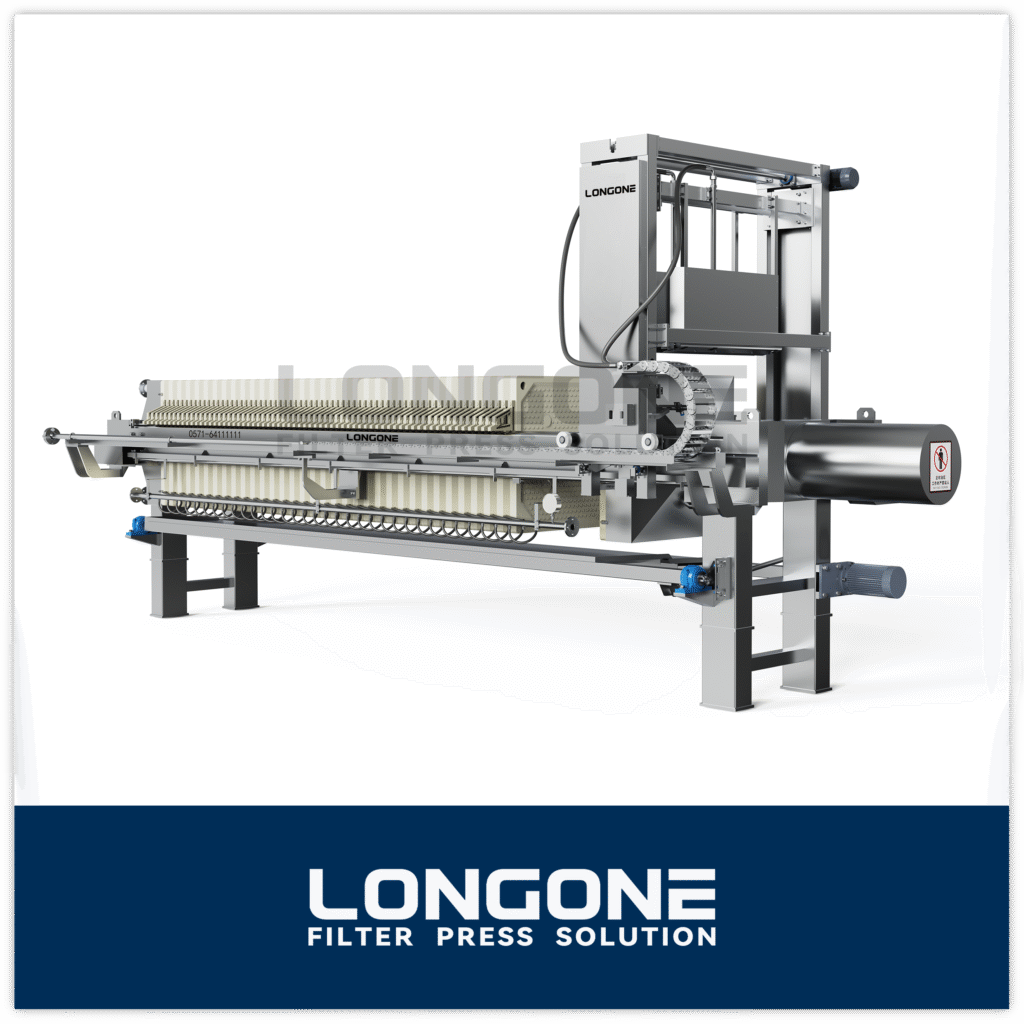

Related products

To meet different application needs, we also offer a full range of filtration solutions, such as the Chamber Filter Press, Frame and Plate Filter Press, Sludge Filter Press, Stainless Steel Filter Press, and Lab Filter Press.

HQ Address

No.111 Fengxiang Road, Tonglu Economic Development Zone, Hangzhou, Zhejiang Province

Email Address

info@longonefiltra.com